Secondary knocking device for aluminum ingot de-molding of aluminum ingot production line

A production line and aluminum ingot technology, applied in the field of aluminum ingot demoulding device, can solve the problems of manpower waste, cost increase, low safety, etc., and achieve the effect of avoiding manpower waste, avoiding production accidents and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

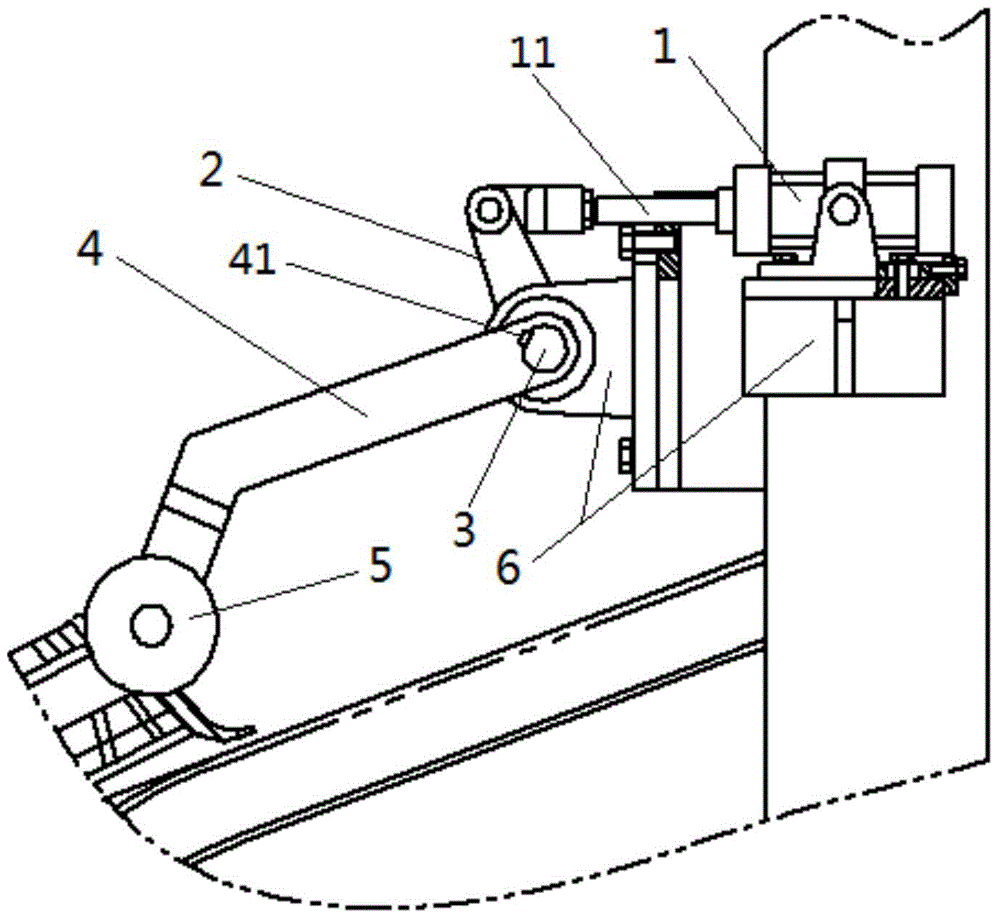

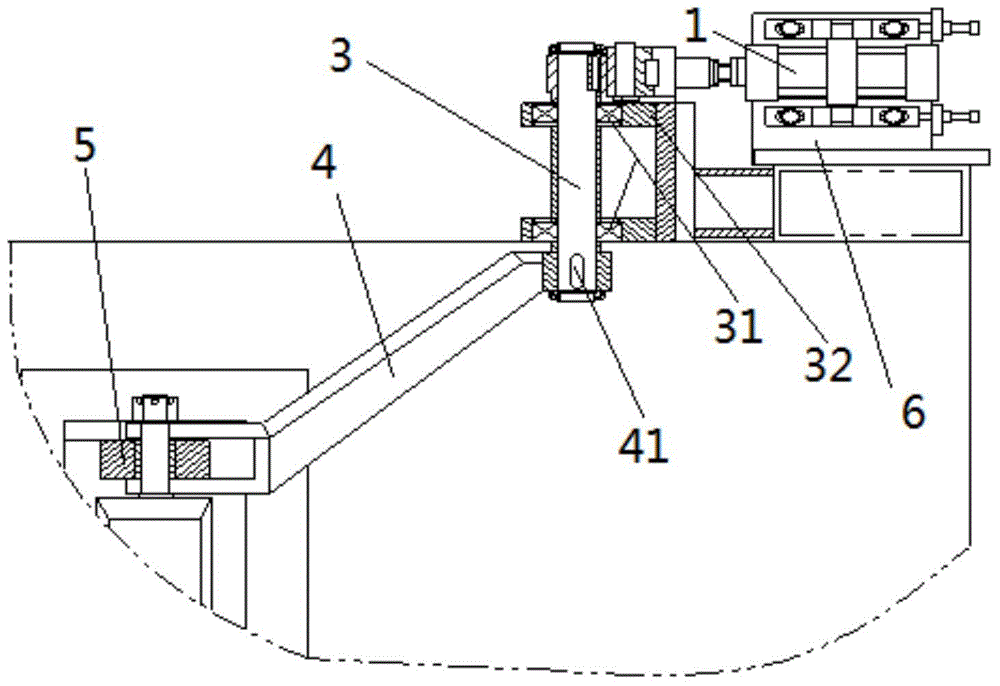

[0016] Such as figure 1 with figure 2 As shown, a secondary knocking device for aluminum ingot demoulding of an aluminum ingot production line includes a cylinder 1, a crank 2, a rotating shaft 3, a connecting rod 4, a hammer 5 and a monitoring device (not shown); the cylinder 1 It is a pneumatic cylinder with a single piston rod, and the cylinder 1 is fixed on the console 6 of the demoulding device of the aluminum ingot production line; the rotating shaft 3 is provided with two bearings 31, and the inner ring of the bearing 31 is fixedly connected with the rotating shaft 3, The outer ring of the bearing 31 is fixedly connected with the bearing mounting frame 32 fixed on the console 6; the free end of the piston rod 11 of the cylinder 1 is correspondingly provided with one end of the crank 2, and a pin or a bolt is arranged in the through hole, so that The free end of the piston rod 11 is rotatably connected to one end of the crank 2, the rotating shaft 3 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com