Hard alloy combined screw tap

A cemented carbide and composite technology, applied in the direction of metal processing equipment, tangent devices, manufacturing tools, etc., can solve the problems of difficult high-speed cutting, poor heat resistance and wear resistance, easy to break, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The cemented carbide composite tap of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

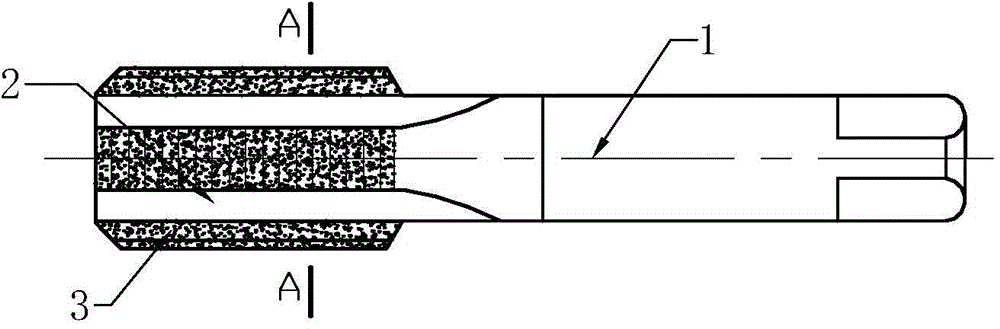

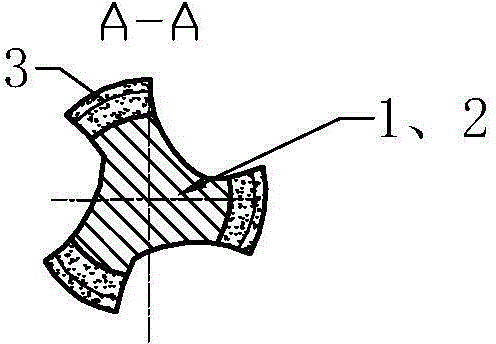

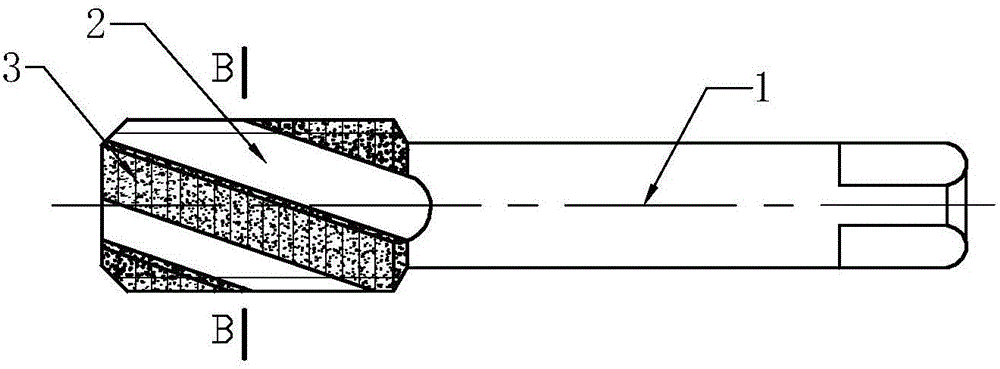

[0019] As shown in the figure, the cemented carbide composite tap of the present invention includes a rod part 1 and a cutting part 2. The cutting part 2 is divided into an inner and outer two-layer structure, and the inner layer structure of the cutting part 2 and the rod part are integrally formed of steel materials. The matrix is formed, that is to say, the lower end of the shank is provided with a cutting part. The shank of the tap and the inner structure of the cutting part 2 (the matrix of the tap) are preferably the same material with high toughness, and the outer structure of the cutting part 2 is a belt. The outer ring 3 with a cutting edge, the outer structure of the cutting part 2 is made of cemented carbide material, that is to say the outer ring is made of cemented carbide material, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com