Polishing grinding machine for LED ceramic bracket

A technology for ceramic brackets and grinding machines, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. It can solve the problems of inconsistent polishing surface effects, low processing efficiency, and affecting processing efficiency. To achieve the effect of ensuring the quality of polishing and grinding, improving the processing efficiency and improving the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

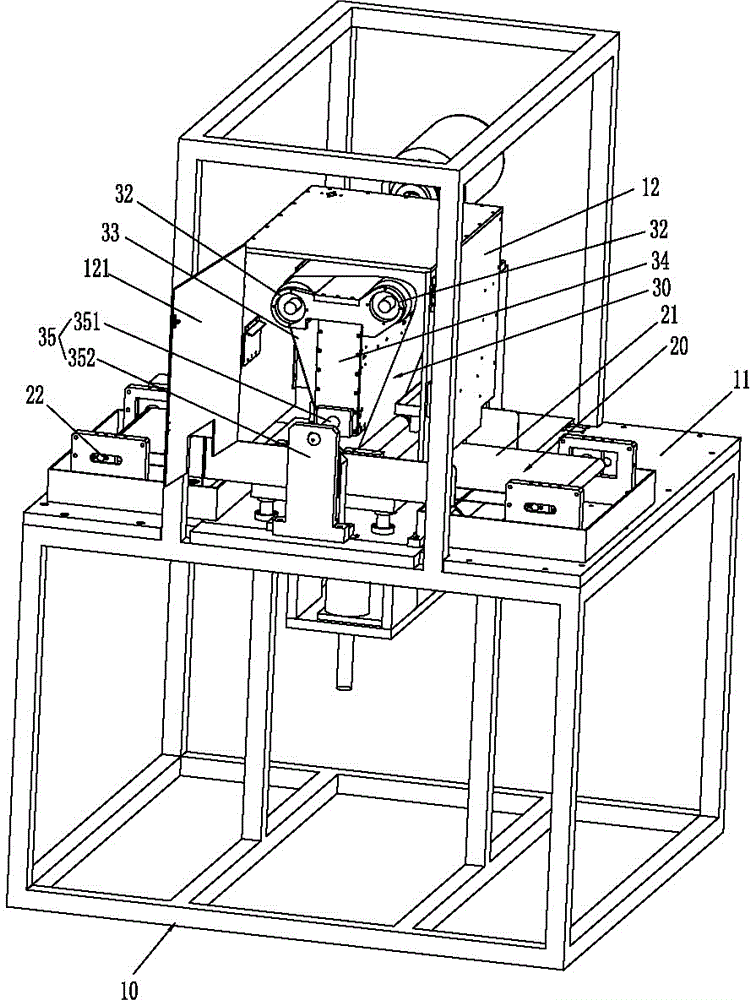

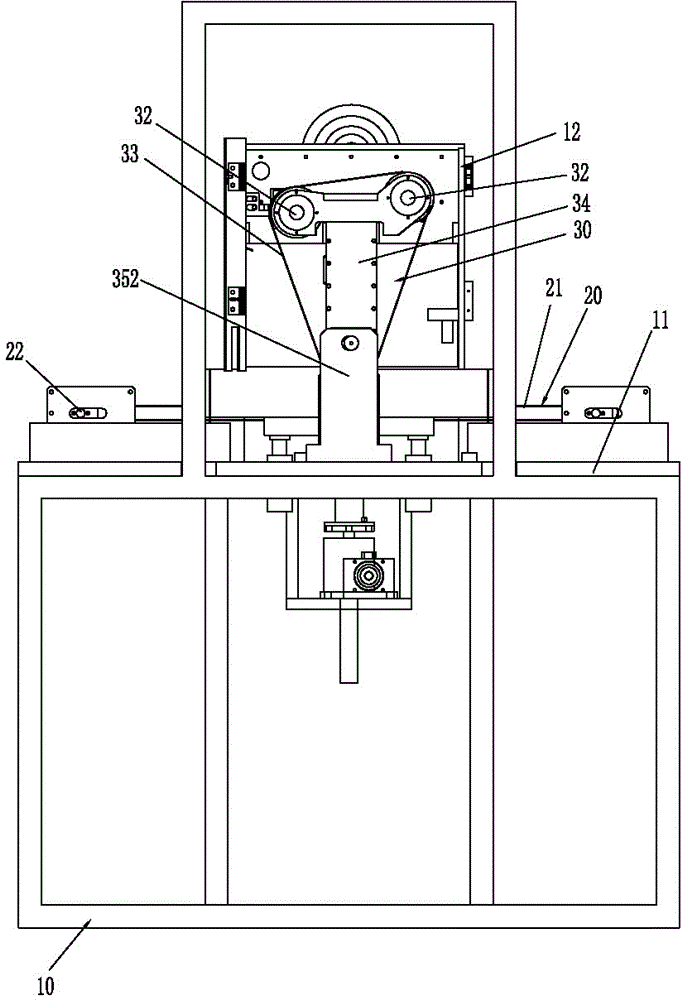

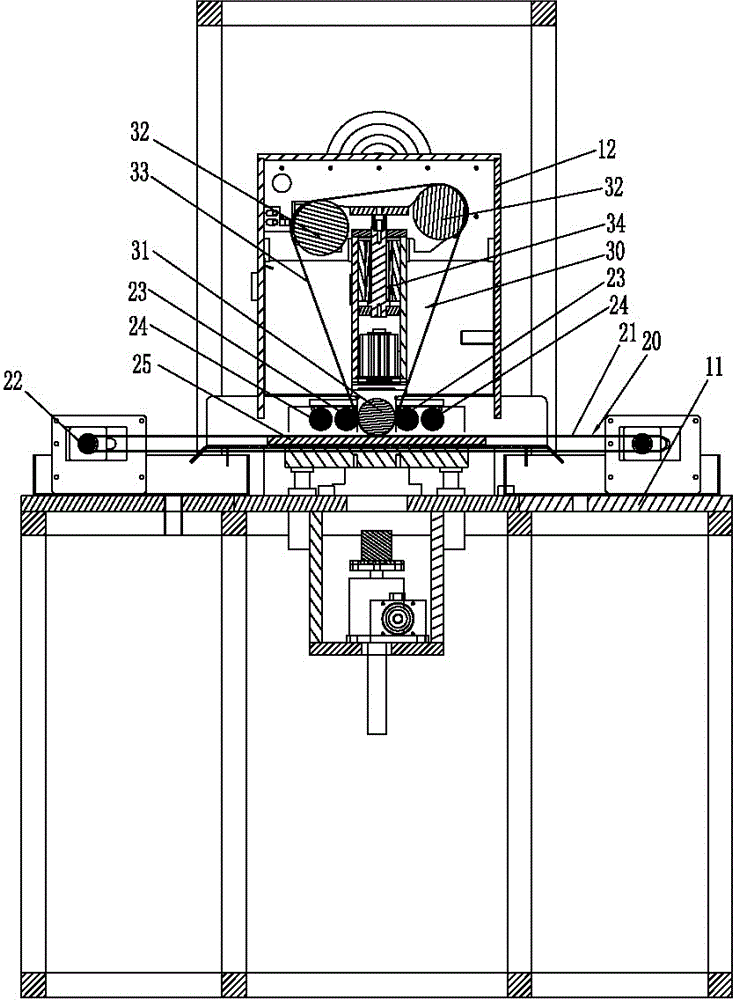

[0045] Please refer to Figure 1 to Figure 8 As shown, it has shown the concrete structure of the embodiment of the present invention, and it comprises frame 10, workpiece conveying device 20, polishing and grinding device 30 and PLC controller 41, wherein, is formed with polishing and grinding work on this frame 10 The platform 11, the workpiece conveying device 20 and the polishing and grinding device 30 are arranged on the polishing and grinding working platform 11, and the PLC controller 41 is connected and controlled to the workpiece conveying device 20 and the polishing and grinding device 30 respectively.

[0046] The workpiece conveying device 20 includes a conveyor belt 21, a conveyor roller shaft 22 for driving the conveyor belt 21 to move horizontally, and a motor for driving the conveyor roller shaft 22. The aforementioned PLC controller 41 is connected and controlled to the motor. Here, the The motor is defined as the first motor 42; the conveyor belt 21 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com