Novel high-speed motor train unit non-power bogie

A technology for high-speed EMUs and power bogies, which is applied in the directions of bogies, devices for lateral relative movement between the underframe and the bogies, and railway car body components, which can solve the problem of unfavorable lightweight design of bogies. , The overall structure of the bogie is complex, and the stress concentration at the joint is large, so as to improve the welding process, optimize the dynamic performance, and reduce the stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

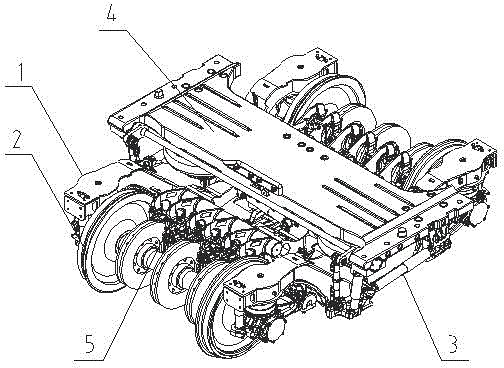

[0015] Such as figure 1 As shown, the non-power bogie of the high-speed EMU mainly includes a frame 1, a wheel-to-axle box positioning device 2, a secondary suspension device 3, a corbel device 4, and a foundation brake device 5.

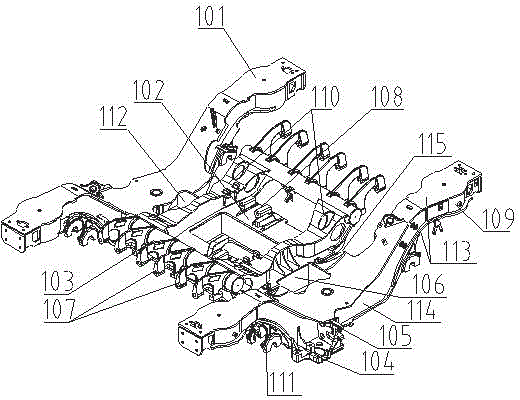

[0016] Such as figure 2 As shown, the frame includes a pair of side beams 101 connected to each other through a pair of cross beams 102. The cross beams and side beams form a hollow box structure. Longitudinal beams 106 are also box structures between the beams. The cross beams 102 adopt four It is welded from one piece of steel plate, and the cross beam side vertical plate 112 is directly inserted into the side beam upper and lower cover plate 113 and connected with the side beam side vertical plate 114; The plates are connected with variable cross-sections through the transition piece 115 . A pair of small longitudinal beams 110 are welded on the longitudinal beam 106, and a pair of brake beam round steel pipes 103 are welded at the ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com