Permanent magnet synchronous direct-drive lifting machine with gear

A permanent magnet synchronous and hoist technology, applied in electromechanical devices, mechanical equipment, control of mechanical energy, etc., can solve problems such as limiting the application of permanent magnet synchronous motors, occupying a large space, and unable to give full play to the advantages of permanent magnet synchronous motors. , to achieve the effect of reducing manufacturing cost and operating cost, reducing volume and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

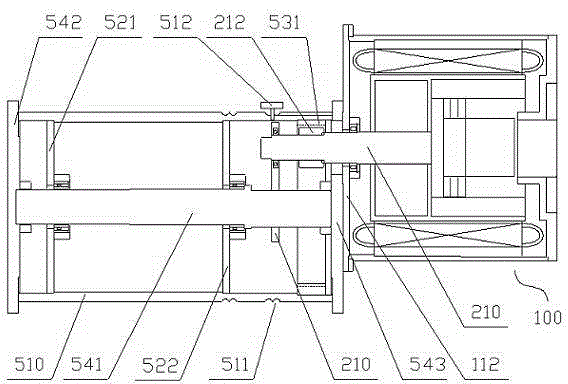

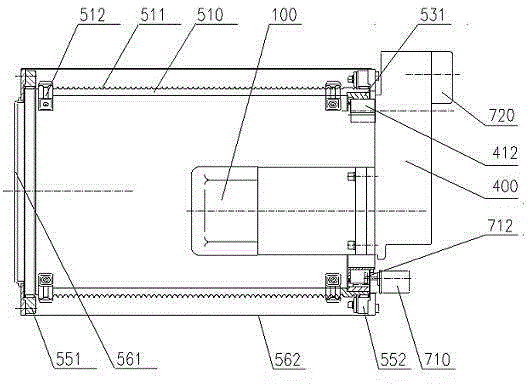

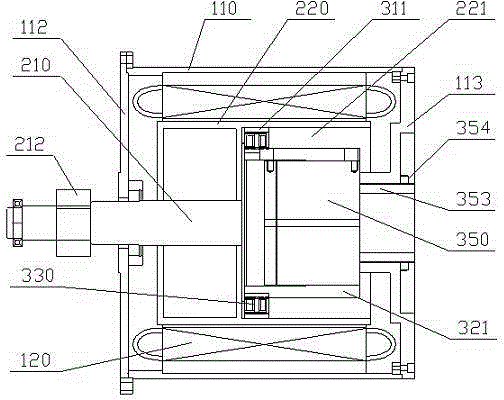

[0012] see Figure 1-5 , a gear permanent magnet synchronous direct-drive hoist disclosed in the present invention includes a hoist base (not shown), a reel 510 rotatably mounted on the hoist base, and a reel for driving the reel to rotate The reel driving device, the outer surface of the reel can usually be provided with a rope groove 511, and is provided with a rope pressing plate or other rope fixing device 512, and the reel driving device uses the permanent magnet synchronous motor 100 as the prime mover, An inner ring gear 531 is provided on the inner wall of the reel, and the driving output gear of the reel driving device meshes with the inner ring gear of the reel. During installation, the outer edge of the inner ring gear can be closely attached to the inner wall of the drum, for example, by means of interference fit or transition fit, and can be set on one side or both sides of the inner ring gear For fixing or protecting the ring gear cover and other parts of the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com