Automatic liquor blending system based on electronic tongue and near infrared spectrum fusion detection

A near-infrared spectroscopy and electronic tongue technology, applied in the field of liquor automatic blending system, can solve problems such as uneconomical, labor-consuming and time-consuming, and the inability of wine tasting staff to give intermediate indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and concrete example further illustrate:

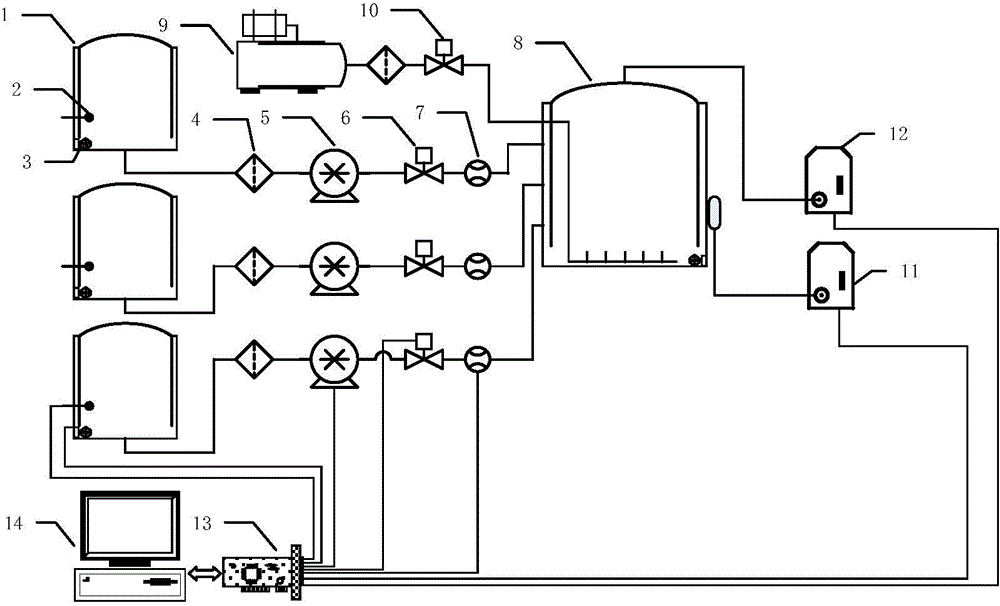

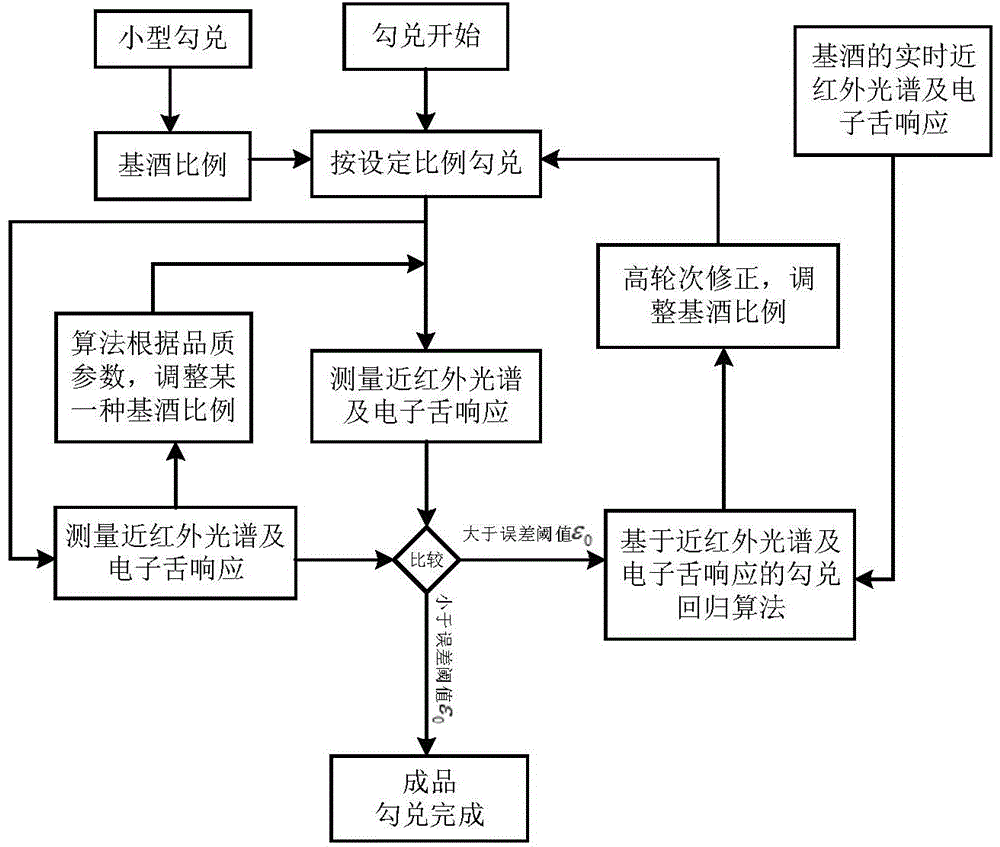

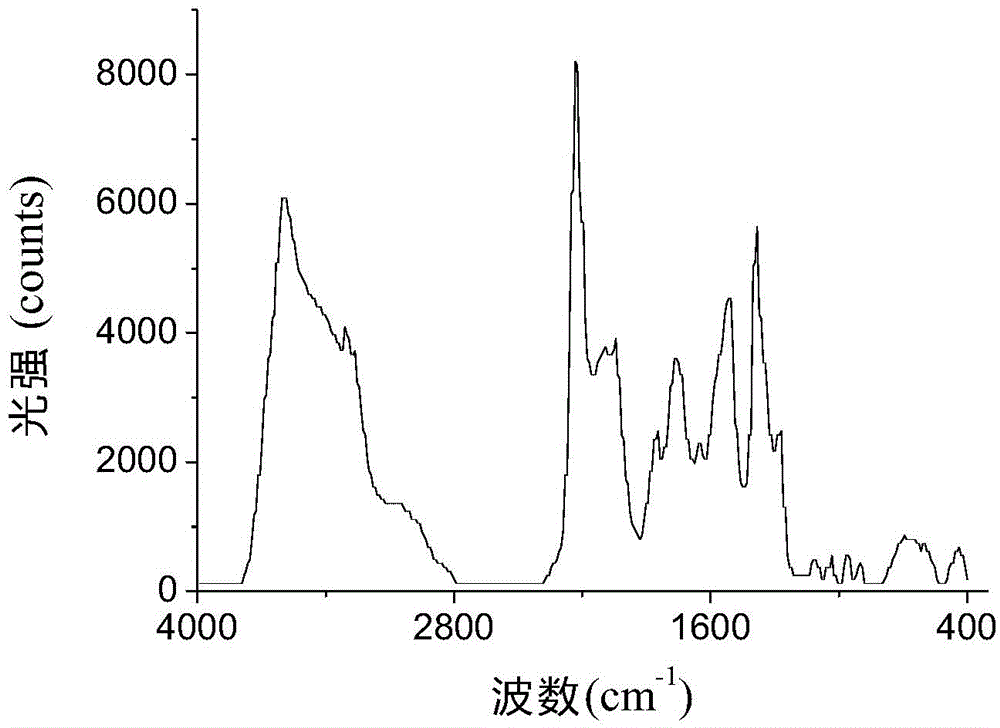

[0020] Before blending, a large number of representative base wine samples should be selected first, and their electronic tongue response and near-infrared spectrum information should be measured to obtain such image 3 The near-infrared spectrum shown and as Figure 4 The electronic tongue response signal is shown. And through mathematical tools such as principal component analysis and partial least squares regression, the quantitative relationship between electronic tongue, spectral information and quality parameters was established. According to the blending process figure 2 , at the beginning of the blending, the initial ratio of each base wine is set according to the formula determined by the small-scale blending (small-pan hook), and the electronic tongue response and spectral information of the small-scale blending products are recorded. After the large-scale blending st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com