Biological fermentation tank with good cooling performance

A bio-fermentation tank, cooling performance technology, applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, biomass post-treatment, etc., can solve the problems of complex manufacturing and processing, and achieve simple production, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

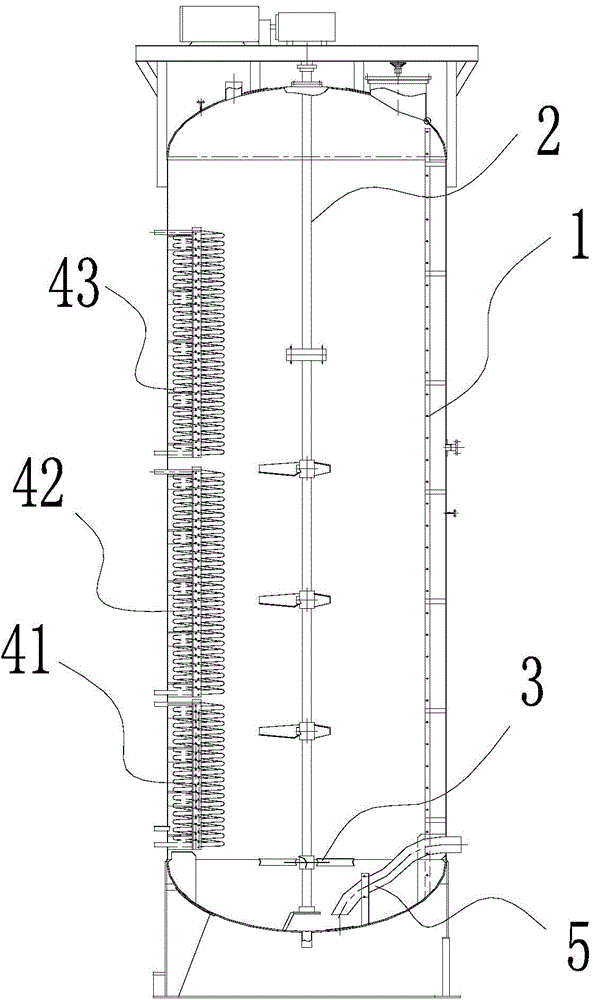

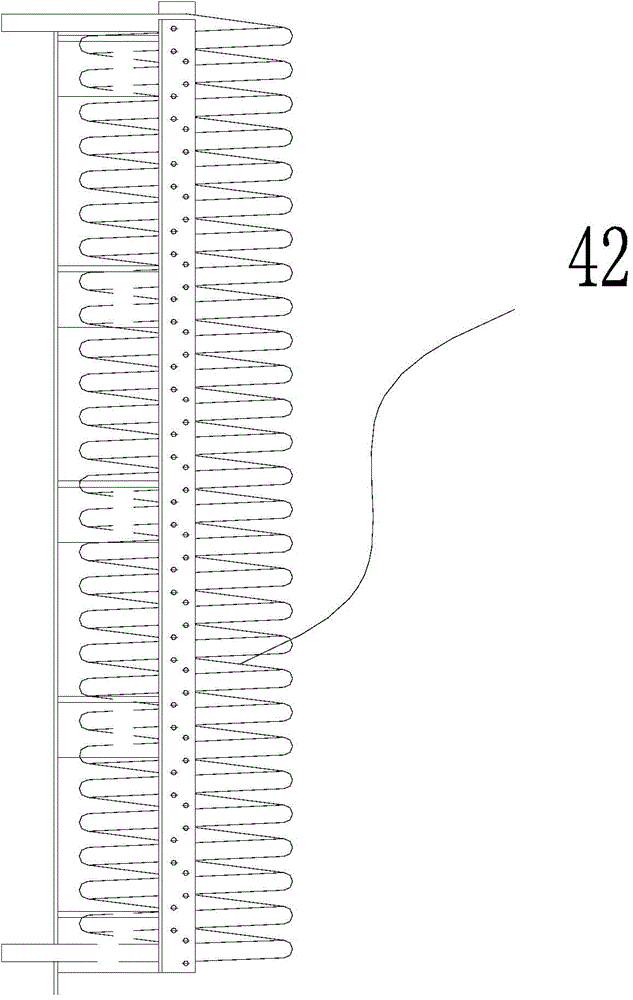

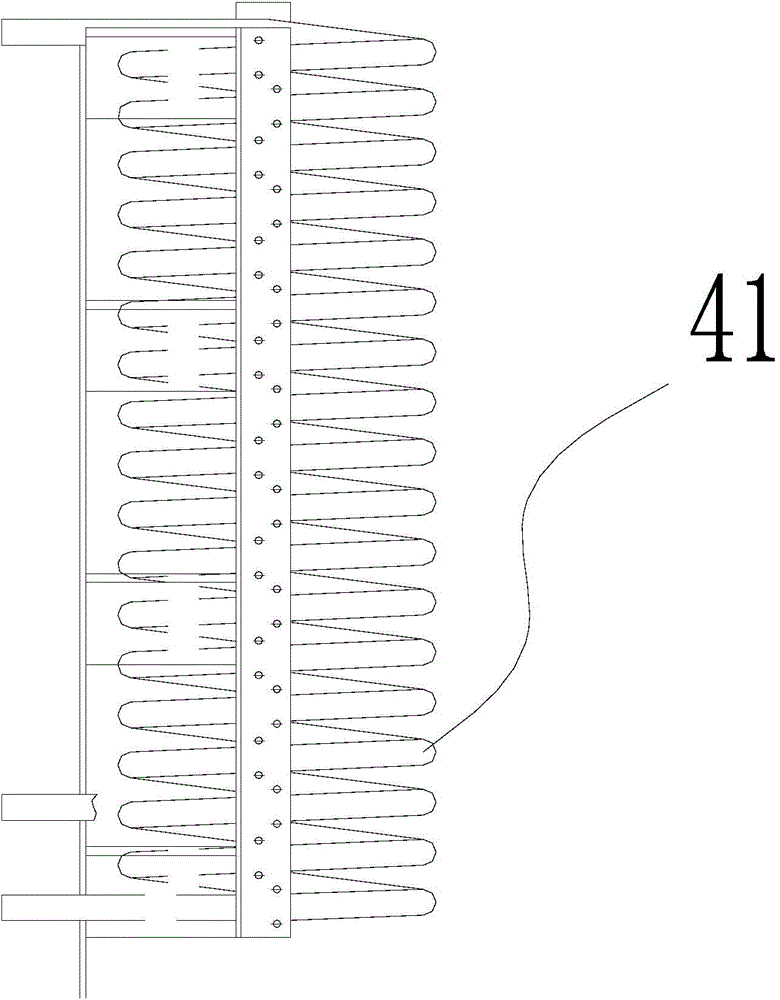

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a biological fermentation tank includes a tank body 1, a coiled tube assembly, an air pipe 5 and a stirring shaft 2, the stirring shaft 2 is vertically arranged in the tank body 1, the stirring shaft 2 is provided with stirring blades 3, and the coiled tube assembly It is arranged on the inner wall of the tank body 1 , and the air tube 5 communicates with the inner cavity of the tank body 1 . A fixed plate is fixed on the snake tube assembly, the fixed plate is fixed to the inner side wall of the tank body through the rib plate, and U-shaped bolts are used for fixing between the fixed plate and the snake tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com