Washer

A washing machine and machine body technology, applied in the field of washing machines, can solve the problems of large space occupation, high cost, manual cleaning of water storage tanks and filter screens, etc., and achieve the effect of convenient installation/disassembly and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

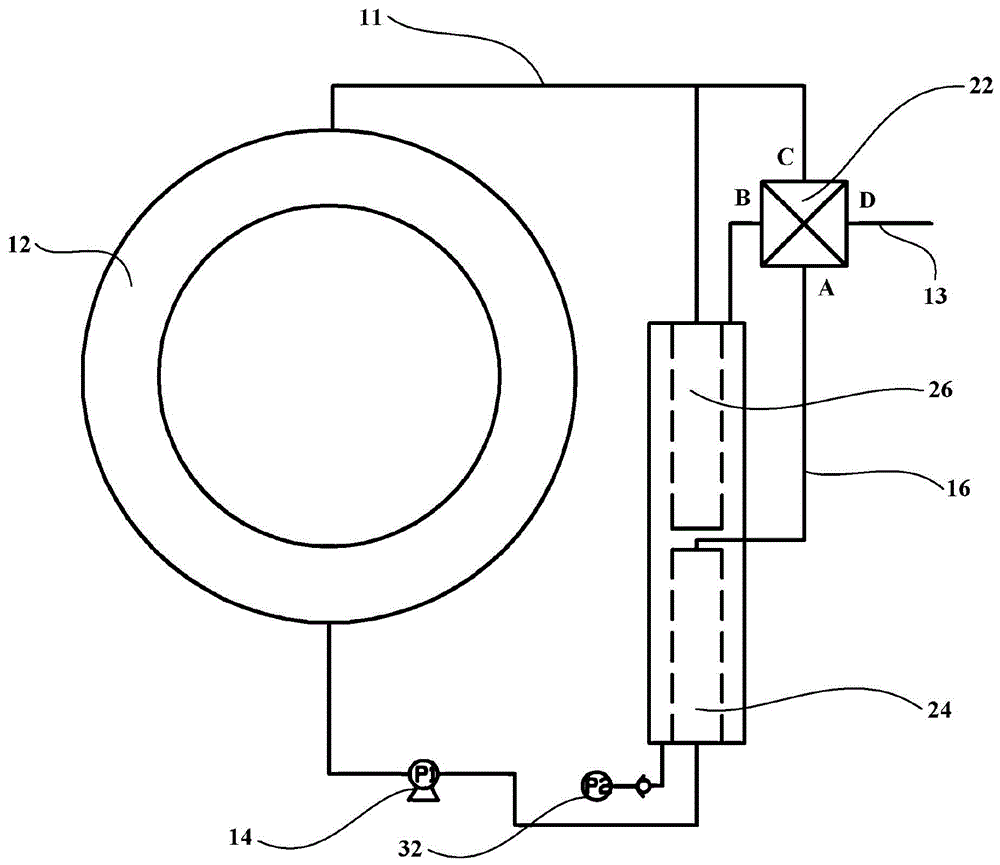

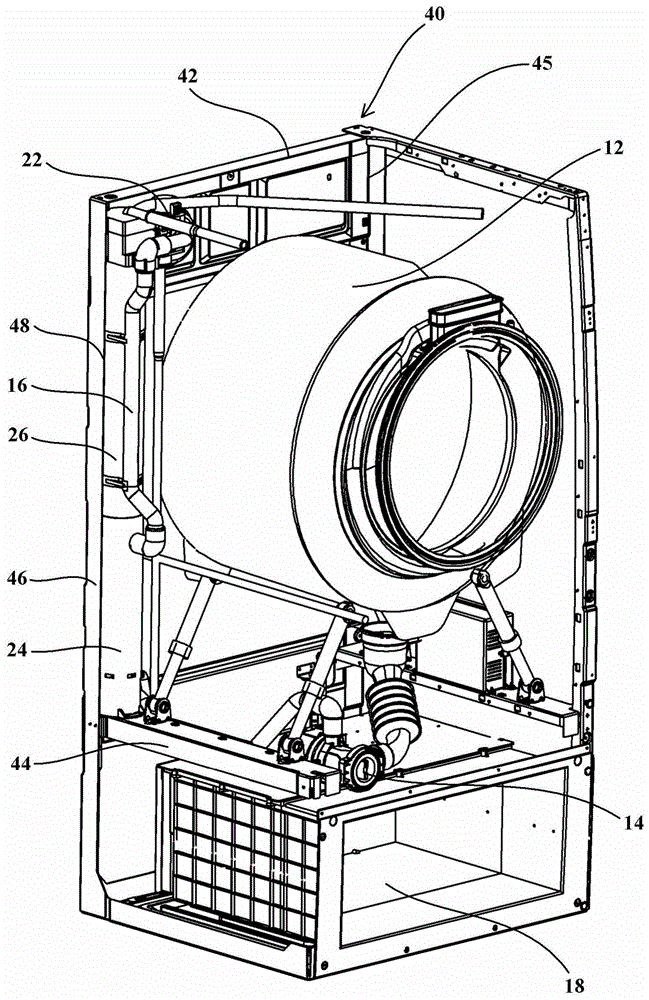

[0045] The washing machine of the present invention may generally include a circulating water filtration system. The circulating water filtering system is configured to: in at least one working process of the washing machine, the water in the washing tub of the washing machine flows into the circulating water filtering system, is filtered in the circulating water filtering system and then circulates back into the washing tub. The at least one working process here can be, for example, one or more rinsing processes or washing processes of the washing machine. For example, when the washing machine is rinsing, the water in the washing tub can flow into the circulating water filtration system, and be filtered and purified in the circulating water filtering system, and then circulate back into the washing tub. In other work processes, such as washing In the process or dehydration process, the water in the washing tub does not flow into the circulating water filtration system for fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com