A vertical vibrating wheel with a built-in reversing mechanism

A reversing mechanism and vertical vibration technology, applied in the field of road rollers, can solve the problems of reduced load, unfavorable assembly and on-site maintenance, and heavy components, so as to reduce the difficulty of assembly and processing, facilitate and efficient on-site maintenance, and simplify the supporting structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

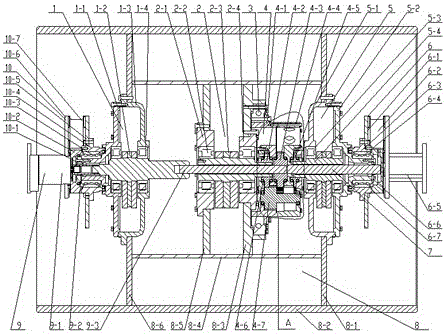

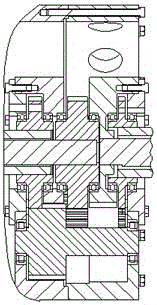

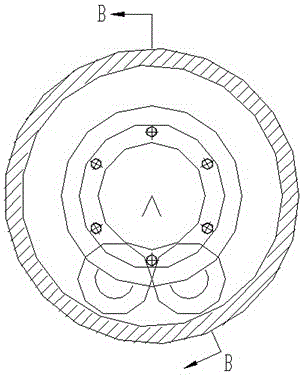

[0025] Such as figure 1 As shown, the present invention includes a vehicle frame, a pressure wheel 8, a left connection assembly 10 arranged inside the pressure wheel 8, a vibration drive assembly 9, a left vibration chamber 1, a middle vibration chamber 2, a gear box 4, a right vibration chamber 5 and a right vibration chamber. Connect the components6.

[0026]Wherein: the left vibration chamber 1 is mainly composed of a left housing 1-3, a left housing cover 1-1, a left vibrator 1-2 and a left vibration bearing 1-4. Among them, the left housing 1-3 and the left housing cover 1-1 form an independent chamber, which is fixedly connected to the pressure roller 8, and the left vibrator 1-2 provided inside it vibrates through the left vibration on both sides. The bearing 1-4 is vertically supported between the left housing cover 1-1 and the left housing 1-3. The right vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com