Mounting method of cross-lane construction support

An installation method and cross-lane technology, which are applied in the field of installation of cross-lane construction supports, can solve the problem that cross-lane construction is not very helpful, and achieve the effects of increasing the degree of interaction, increasing local stiffness and overall stiffness, and reducing load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

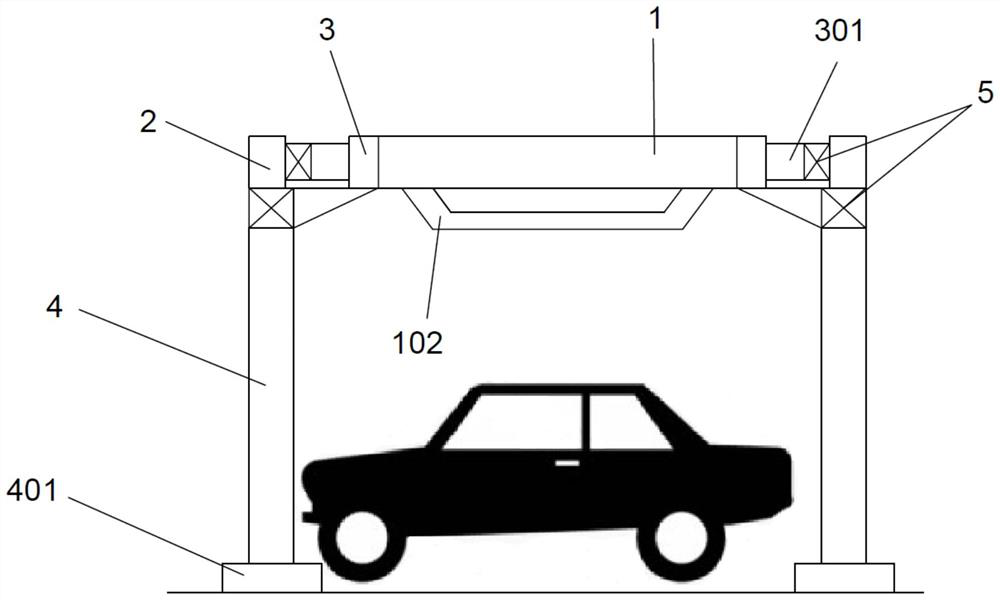

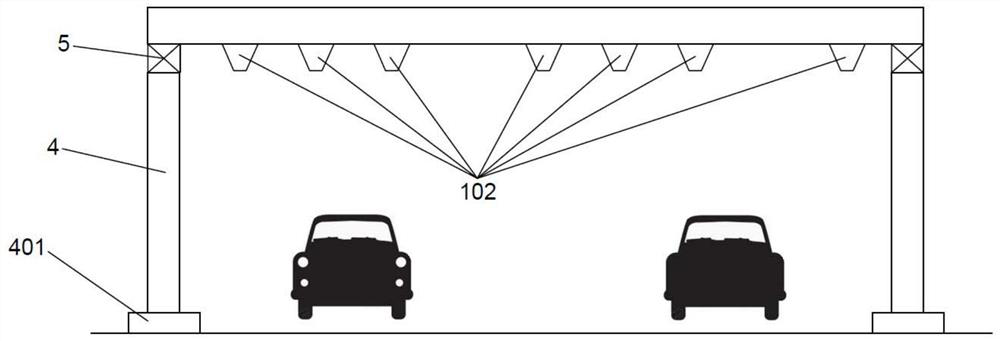

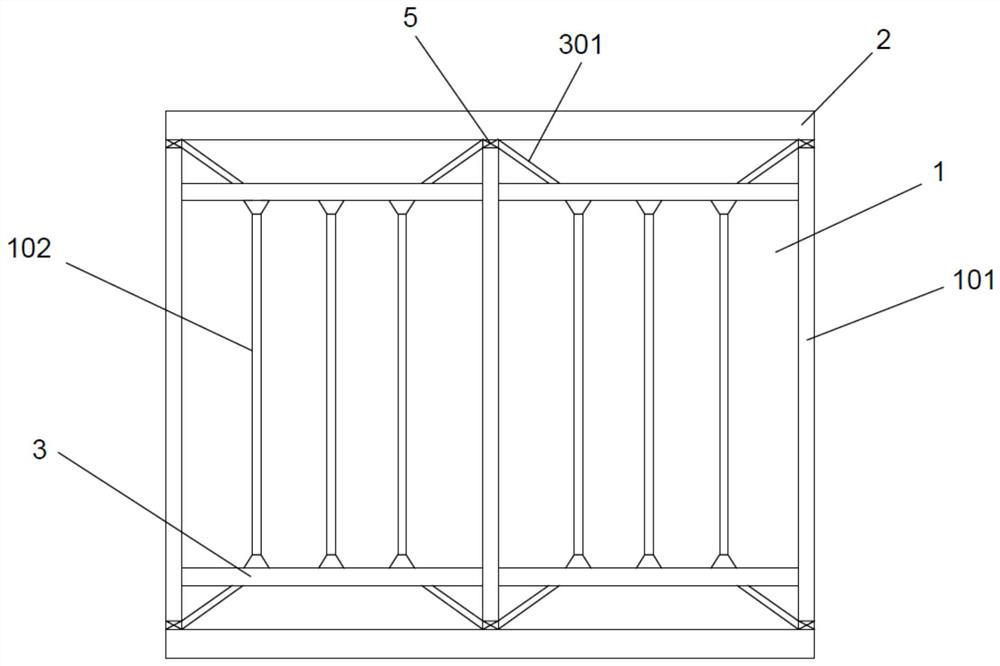

[0033] This application relates to an installation method of a cross-lane construction support, which can increase the overall rigidity of the construction support and reduce the local deformation of the construction support surface under the premise of meeting the construction strength requirements and construction costs. Work together to increase the local stiffness of the construction support.

[0034] According to a preferred embodiment, a half-meter-shaped support 301 is provided between the main longitudinal beam 2 and the sub-longitudinal beam 3 of the construction support surface 1; Based on the long-wave effect after the deformation of the construction support surface 1, the structural optimization for improving the overall vertical stiffness of the construction support is given; based on the deformation and stress state of the construction support surface 1 of the sub-longitudinal beam 3, the Describe the position of sub-longitudinal beam 3; based on the deformation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com