Angular drill

A drilling rig and drilling rig platform technology, which is applied to drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve problems such as construction difficulties, and achieve the effects of reasonable placement, large drilling stroke, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

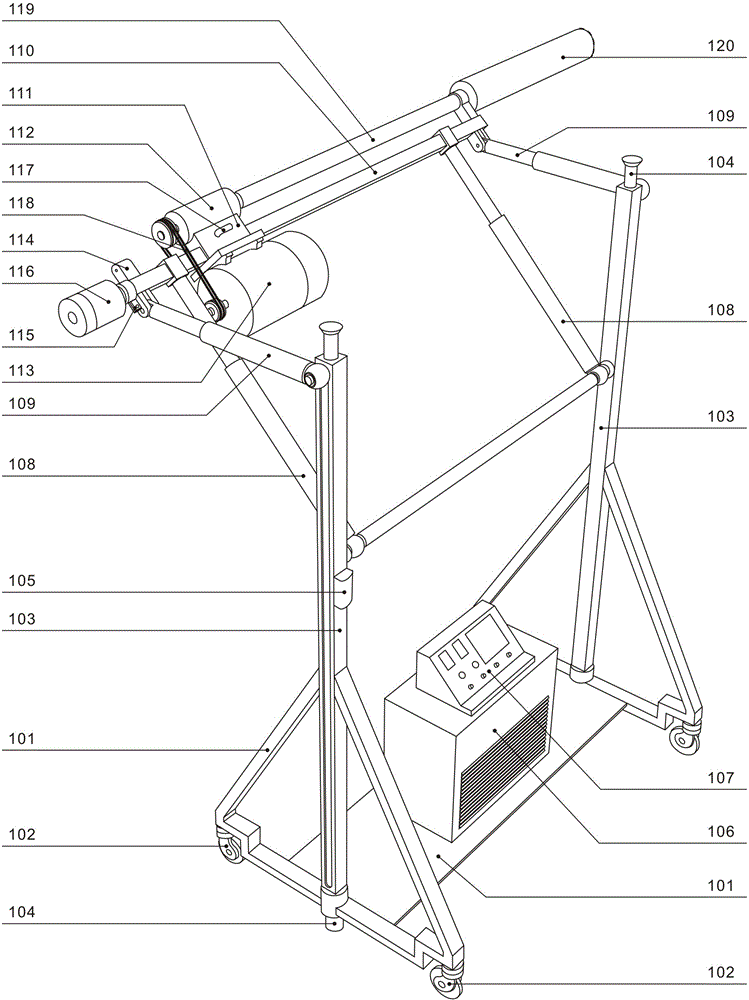

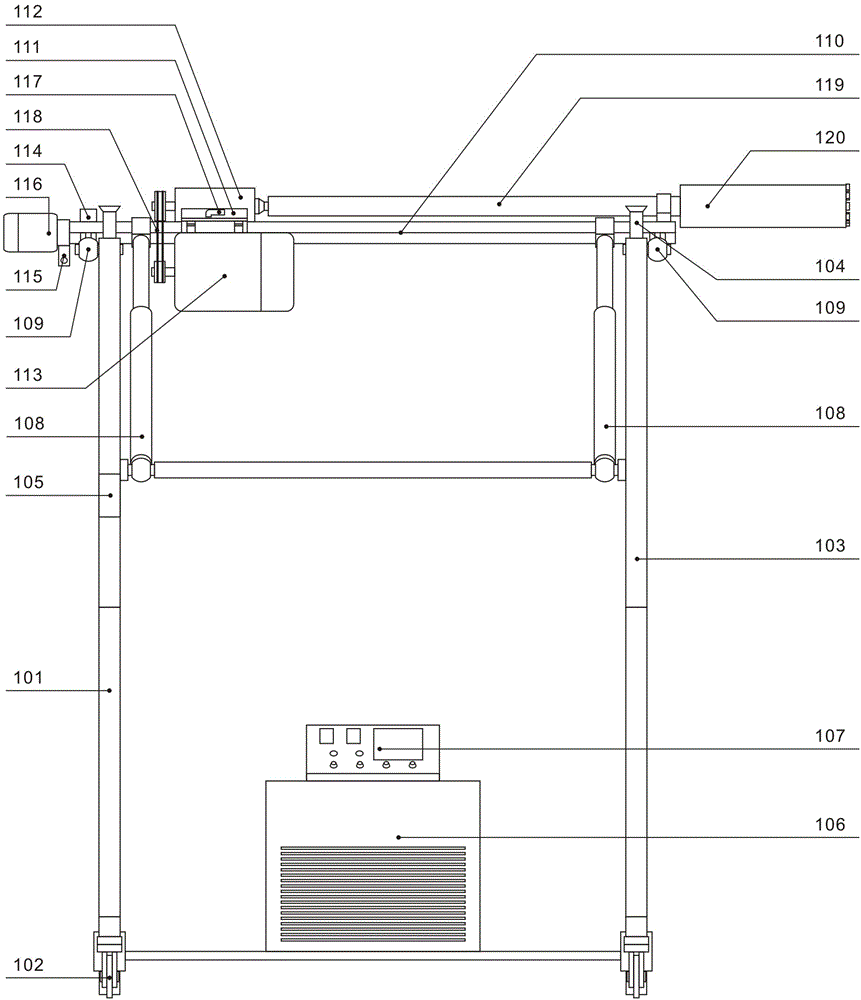

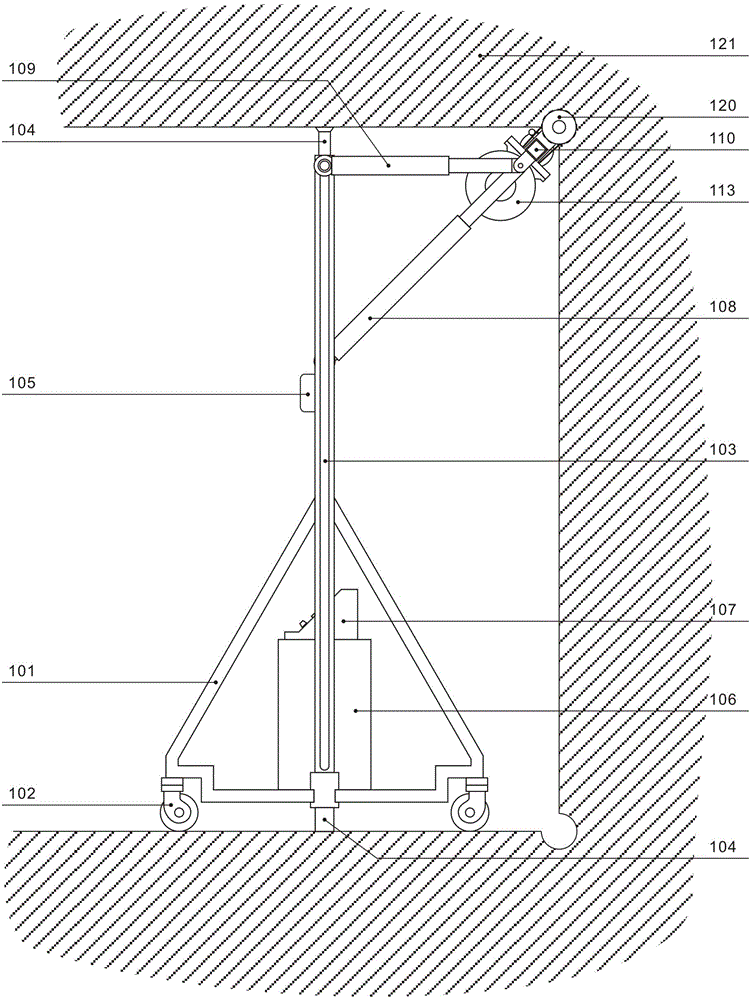

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings. according to figure 1 , figure 2 , image 3 Shown, the present invention is made up of following parts: drilling rig platform, three-link support mechanism, drilling rig. The drilling rig platform includes: frame 101, universal wheels 102, level measuring instrument 105, cabinet 106, console 107; four universal wheels 102 are arranged below the frame 101; the level measuring instrument 105 is arranged on the machine 101 on the frame; the cabinet 106 is arranged on the frame 101, and a hydraulic pump station, a frequency converter, a circuit breaker and various electrical equipment are arranged in the cabinet 106; the console 107 is arranged on the cabinet 106, and can Do 360 degree rotation on the console 107, the display and control interfaces of various hydraulic pressure and electrical equipment are concentrated. The three-link support mechanism is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com