Two-dimensional variable geometry hypersonic intake port provided with rectangular inlet as well as design method and working method of two-dimensional variable geometry hypersonic intake port

A hypersonic and air inlet technology, which is applied in the direction of mechanical equipment, jet propulsion devices, gas turbine devices, etc., can solve the problems of restricting the starting performance of the inlet port, sacrificing the flow capture ability, and large overflow loss, so as to improve the flow capture capacity, broaden the working range, and reduce the effect of flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and technical characteristics of the present invention more clear, the following will be further described in detail in conjunction with the accompanying drawings and implementation examples. The implementation examples described below are only used to explain the present invention, and do not limit the present invention.

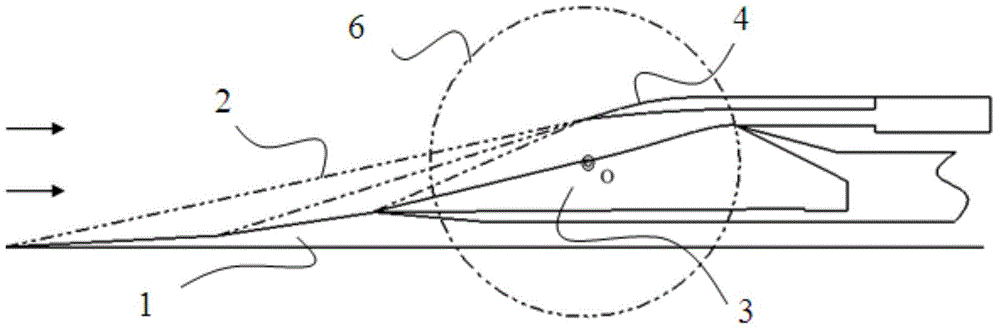

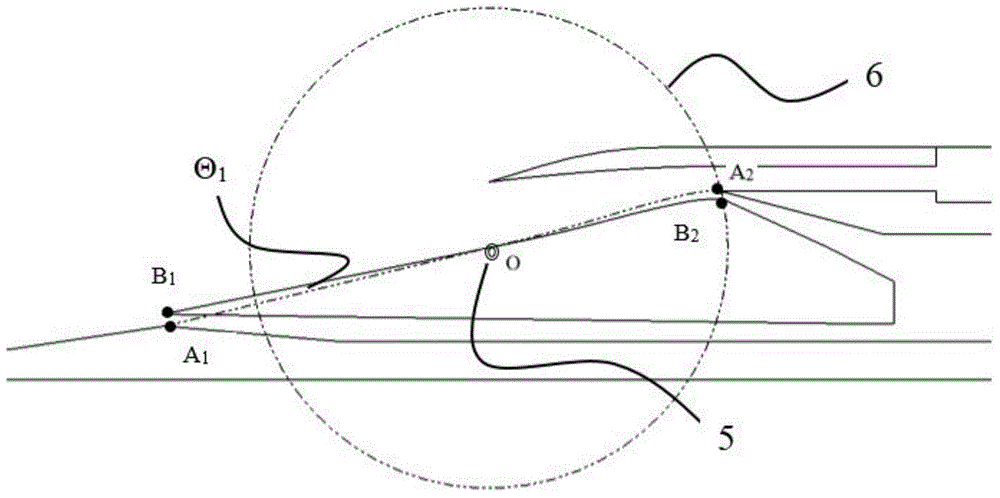

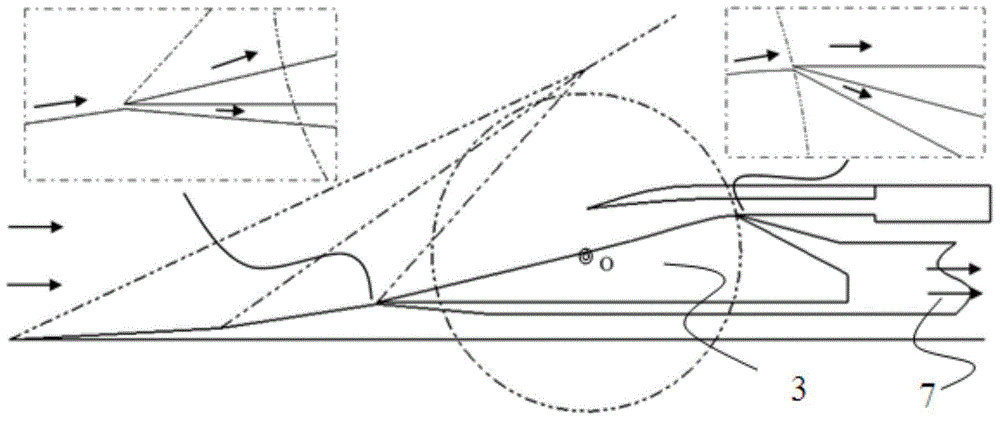

[0033] Such as figure 1As shown, the rectangular inlet binary hypersonic variable geometry inlet of the present invention includes: a hypersonic aircraft body 1, a rectangular lip cover 4, an adjustable top plate 3 and an actuating mechanism, the actuating mechanism can be selected as a cylinder or a gear shaft to rotate . The hypersonic flight precursor in the body 1 of the hypersonic vehicle can be any one of the conventional hypersonic inlets, such as the binary wedge surface compression precursor, the three-dimensional curved surface compression precursor, and the waverider precursor. The adjusta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com