Hollow blade wall thickness parameter measuring device

A technology of parameter measurement and hollow blade, which is applied in the direction of electromagnetic measuring device, electric/magnetic thickness measurement, etc., can solve the problems of measurement accuracy influence, probe diameter and anti-interference ability can not meet the requirements of field use, etc., to achieve small diameter, diameter Reasonable and well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

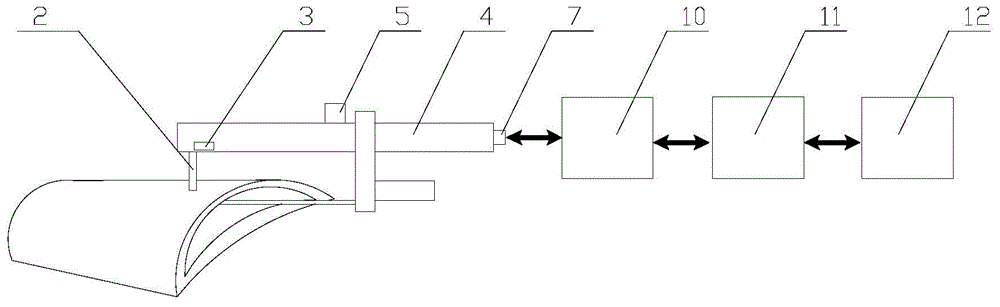

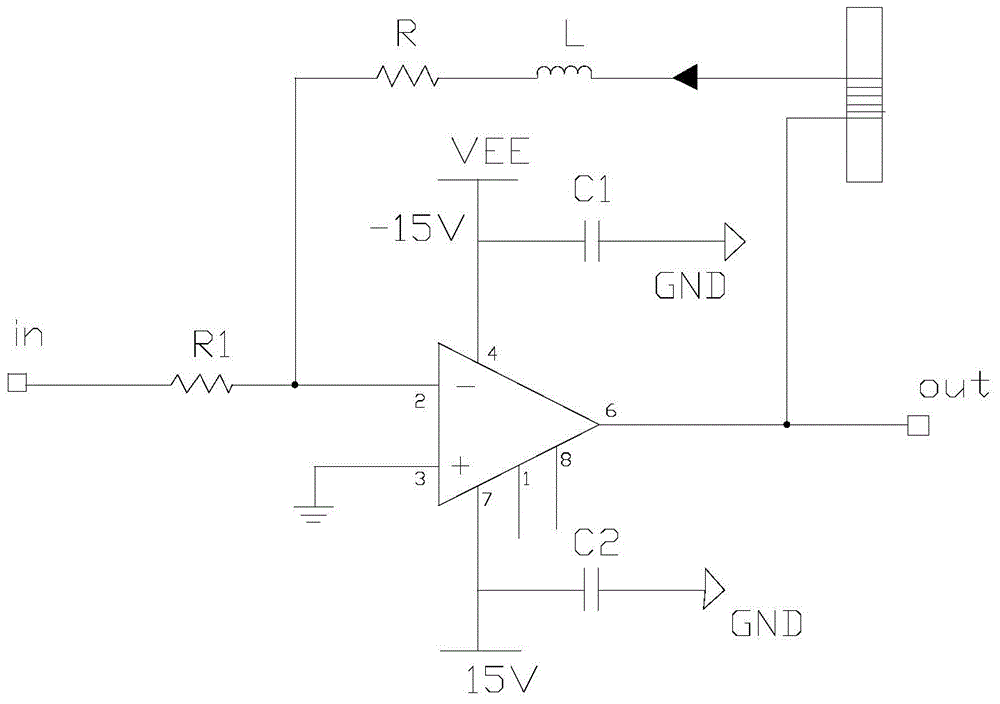

[0009] As shown in the figure, the specific technical solution of the present invention is that the hollow blade wall thickness parameter measurement device includes a data acquisition structure and a measurement device controller 10, and the data acquisition structure includes a measurement handle 4 and an eddy current set on the measurement handle 4 Sensor 2, temperature sensor 3, measurement record button 5, connection plug 7, the I / O port of described eddy current sensor 2, temperature sensor 3, measurement record button 5 is connected to measurement device controller 10 through connection plug 7, so The measuring device controller 10 described above comprises a sequentially connected constant current source excitation circuit, a preamplifier circuit, a narrowband bandpass filter circuit, a true effective value conversion circuit, data processing and a compensation circuit, and the constant current source excitation circuit includes an amplifier, an inductor L , input resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com