Non-Destructive Evaluation of Structures Using Motion Magnification Technology

A non-destructive, motion-amplifying technology that can be used in machine/structural component testing, material analysis using sonic/ultrasonic/infrasonic waves, strength properties, etc., and can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

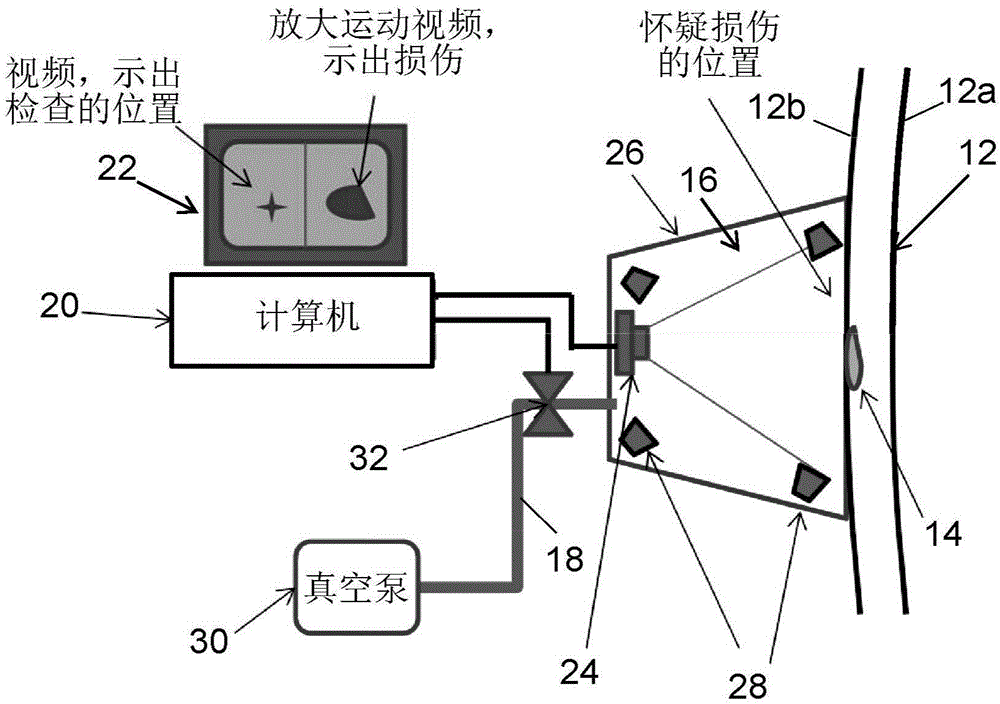

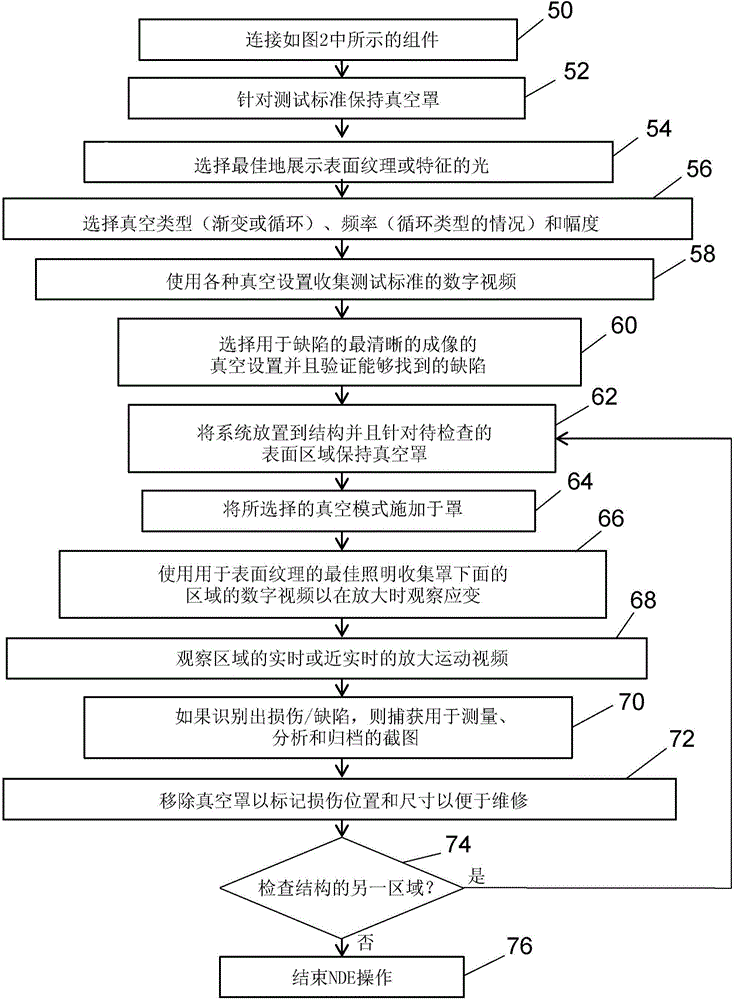

[0025] Embodiments of systems and methods for performing non-destructive assessment of structures using motion magnification techniques will now be described. The following systems and methods for monitoring structural testing using motion magnification techniques will be described.

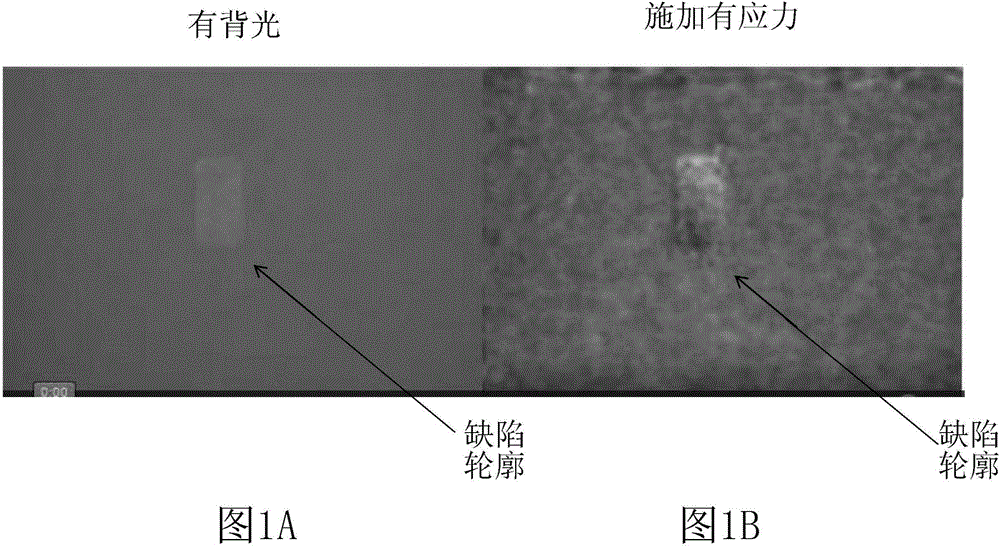

[0026] To prove the concept of using motion magnification techniques to perform non-destructive evaluation of structures, tests were performed in which a 3 / 4 inch by 1 inch defect was machined into the backside of a 1 / 8 inch thick composite layup. In the first part of the test, light was applied to the back of the stack and a video was recorded of the area on the anterior skin overlapping the machined defect. Figure 1A is a screencast video image of a backside lit stackup showing the outline of a machined defect, which would normally not be visible from the front. In the second part of the test, strain was created (ie, stress was applied) using a partial vacuum source attached to the backside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com