Testing method of microscale tension of two self-polymeric proppant particles

A test method and proppant technology, applied in the direction of measuring devices, instruments, and mechanical devices, etc., can solve the problems of objective evaluation of the cohesion performance of refractory self-polymerizing proppants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

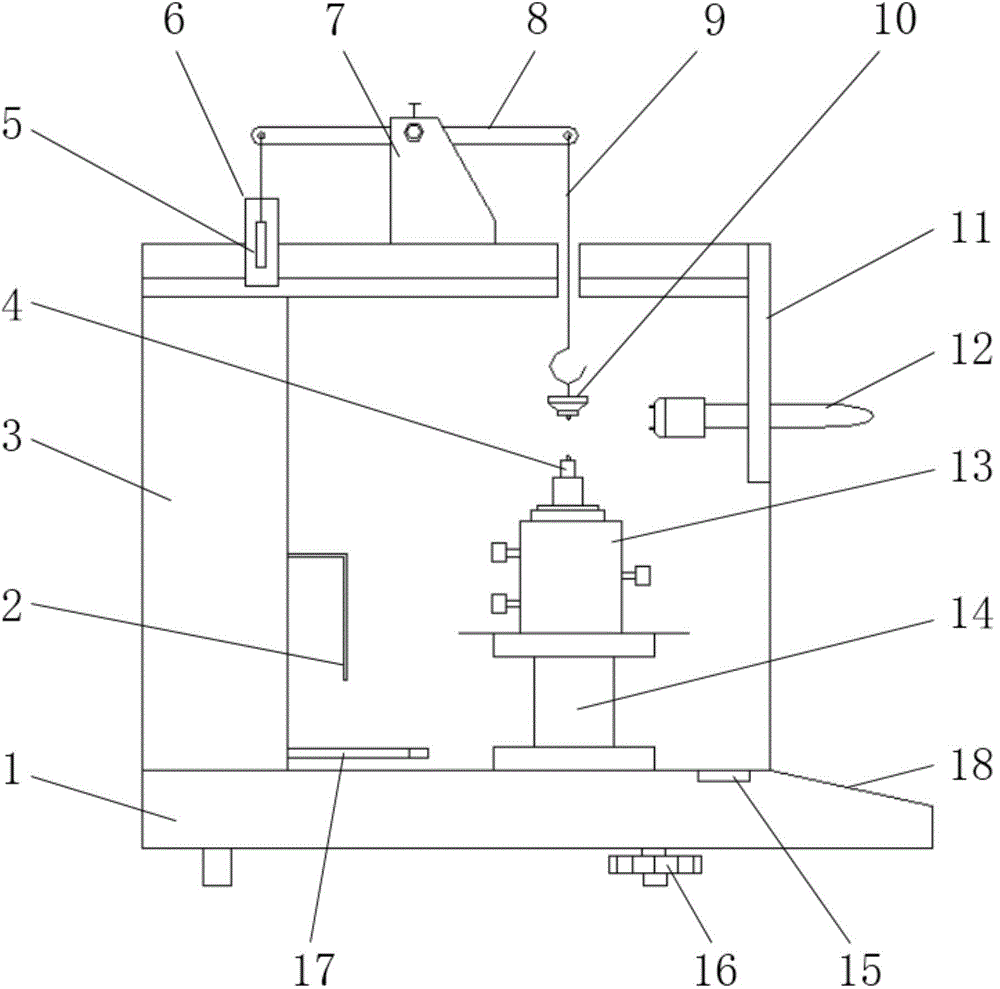

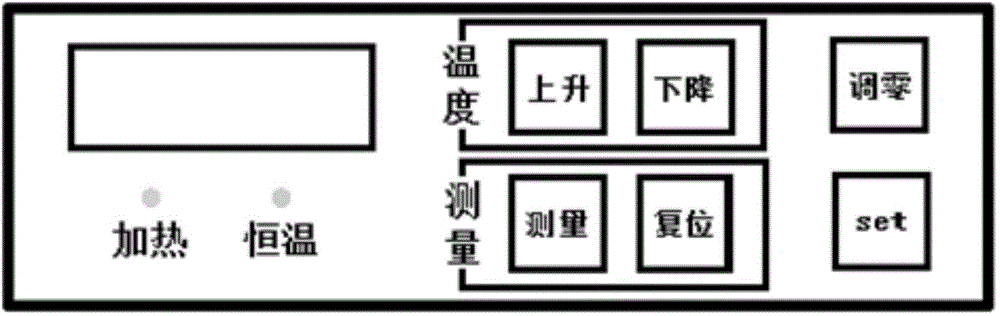

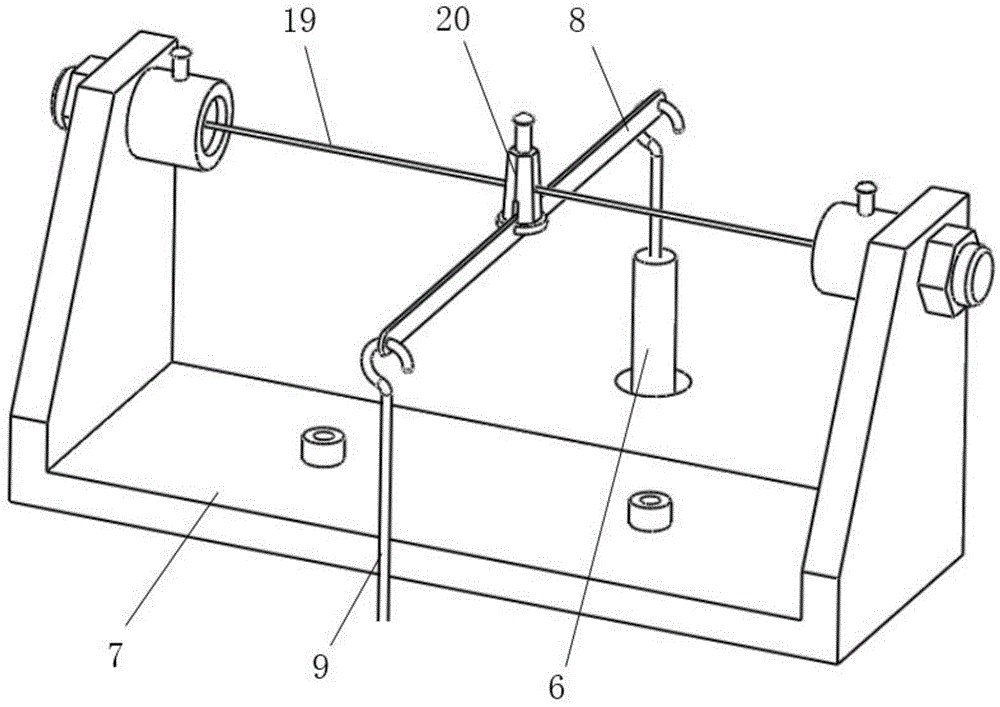

[0023] Below in conjunction with accompanying drawing and example the present invention will be further described:

[0024] Such as Figure 1-3 Shown, a kind of testing method of micro-tension between two self-aggregating proppant microparticles of the present invention, the technical scheme comprises the following steps:

[0025] (1) Prepare 500ml of KH-560 coupling agent solution with a mass fraction of 0.5% to 1.0%, and add acetic acid to adjust its pH value to between 3.5 and 5.5;

[0026] (2) Weigh 100g of 20 / 40 mesh ceramsite proppant commonly used in oil field fracturing, first wet the surface of ceramsite proppant with distilled water, then mix with coupling agent solution and stir at 200r / min for 15 minutes, Take out and dry;

[0027] (3) Weigh 3g of bisphenol A epoxy resin and 47g of proppant treated with coupling agent, mix them and place them under the sand mixing mixer at a speed of 400r / min for 3 minutes to prepare Obtain self-aggregating proppant with uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com