Measuring system and method for refractive index of optical material

An optical material and measurement system technology, applied in the measurement of phase influence characteristics, etc., can solve the measurement system measurement accuracy laser power fluctuation, air disturbance and vibration influence, can not meet the development needs of high refractive index materials and new materials, limit samples Refractive index range and measurement accuracy, etc., to achieve the effect of strong environmental anti-interference, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The measurement system and method for measuring the refractive index of optical materials provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

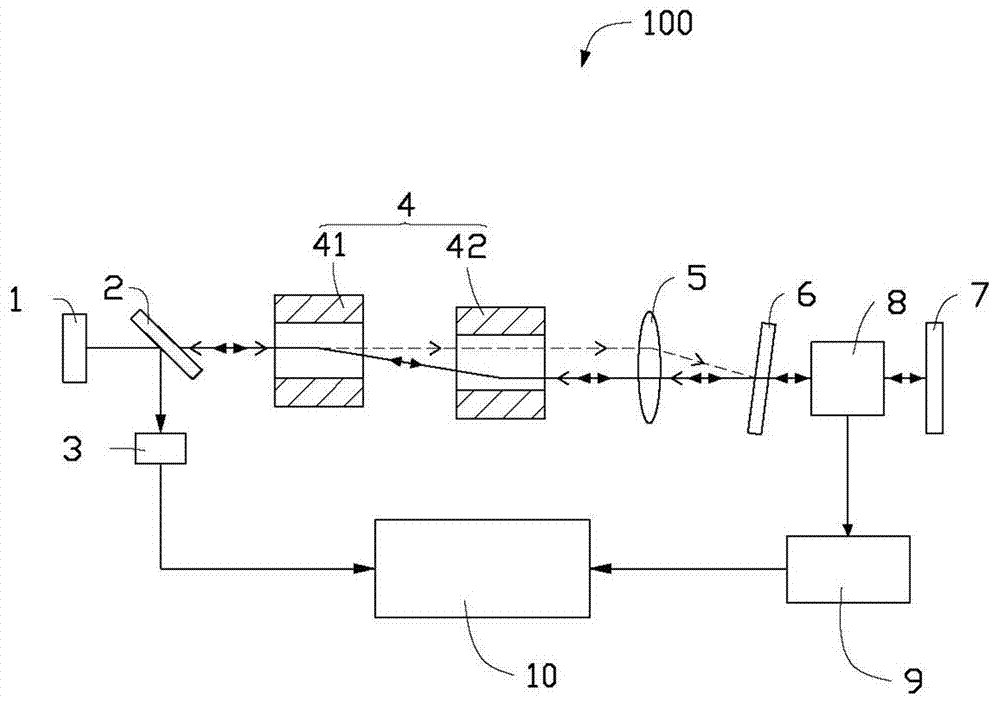

[0031] see figure 1 The optical material refractive index measurement system 100 provided by the embodiment of the present invention includes a laser module 1, a beam splitter 2, a photoelectric detection module 3, an acoustic optical frequency shift module 4, a reference feedback mirror 6, and a measurement Feedback mirror 7 , a displacement device 8 , a displacement detection device 9 and a signal processing system 10 .

[0032] The laser module 1 is used to output laser light. The laser module 1 can be a full inner cavity, a half outer cavity or a full outer cavity, can use a solid-state laser or a semiconductor laser, and can output laser light continuously. Preferably, the working mode of the laser module 1 is a single longitudinal mode and a fundamental trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com