Airbag overall dimension detection method based on binocular vision

An airbag and detection method technology, applied in the fields of computer vision and image measurement, can solve problems such as low efficiency, safety hazards, and high detection costs, and achieve the effects of cost reduction, strong adaptability, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Referring to the accompanying drawings, specific embodiments of the present invention will be described in more detail below.

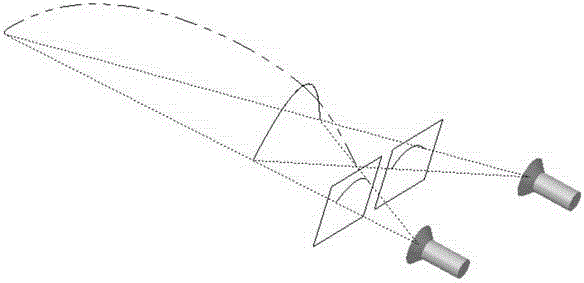

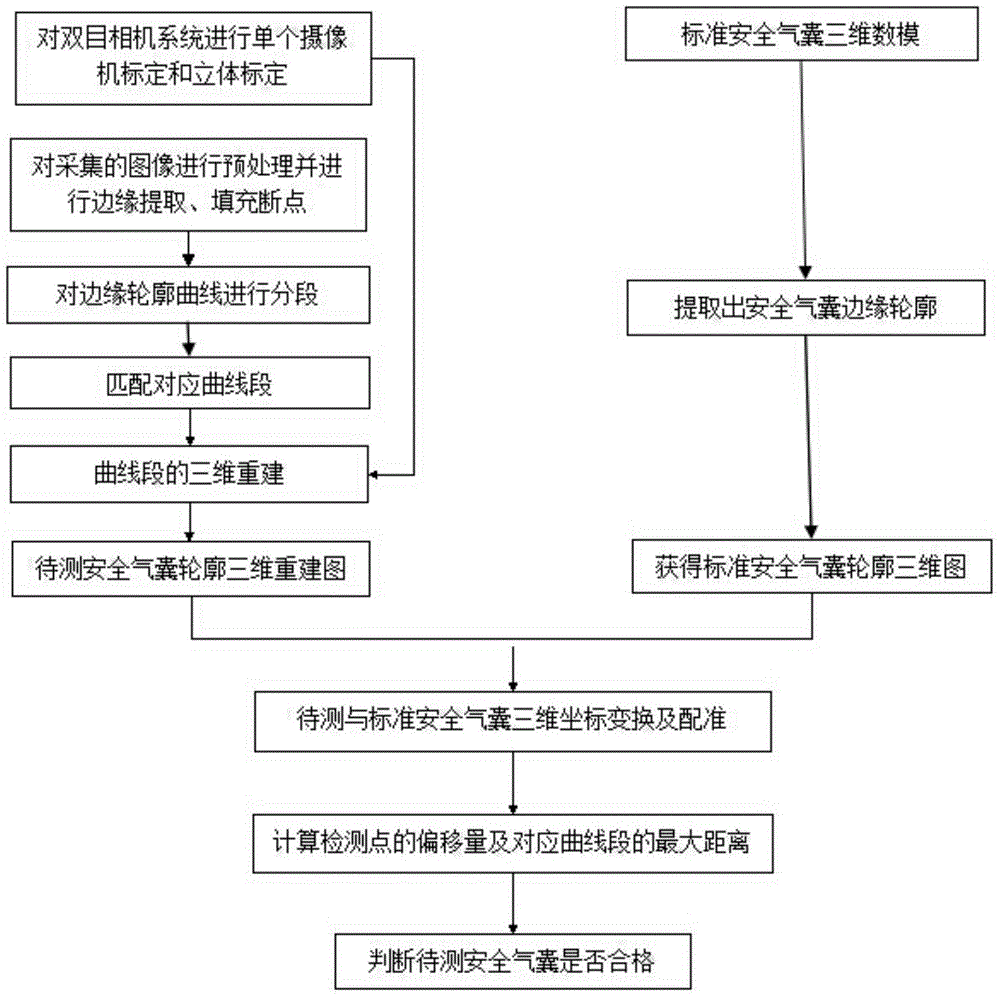

[0016] figure 1 It is a flow chart of the airbag outline size detection method based on binocular vision of the present invention, and a binocular vision-based airbag outline size detection method comprises the following steps:

[0017] (1) Calibration of binocular stereo vision system. The calibration of the camera is to obtain the internal and external parameters of the camera. Use the MATLAB calibration toolbox to perform single-camera calibration on the two cameras to obtain the internal and external parameters of each camera, and then use the Open CV in VS2010 to calibrate the camera. Stereo calibration is performed to obtain the rotation matrix R and translation matrix T of the positional relationship between the two cameras.

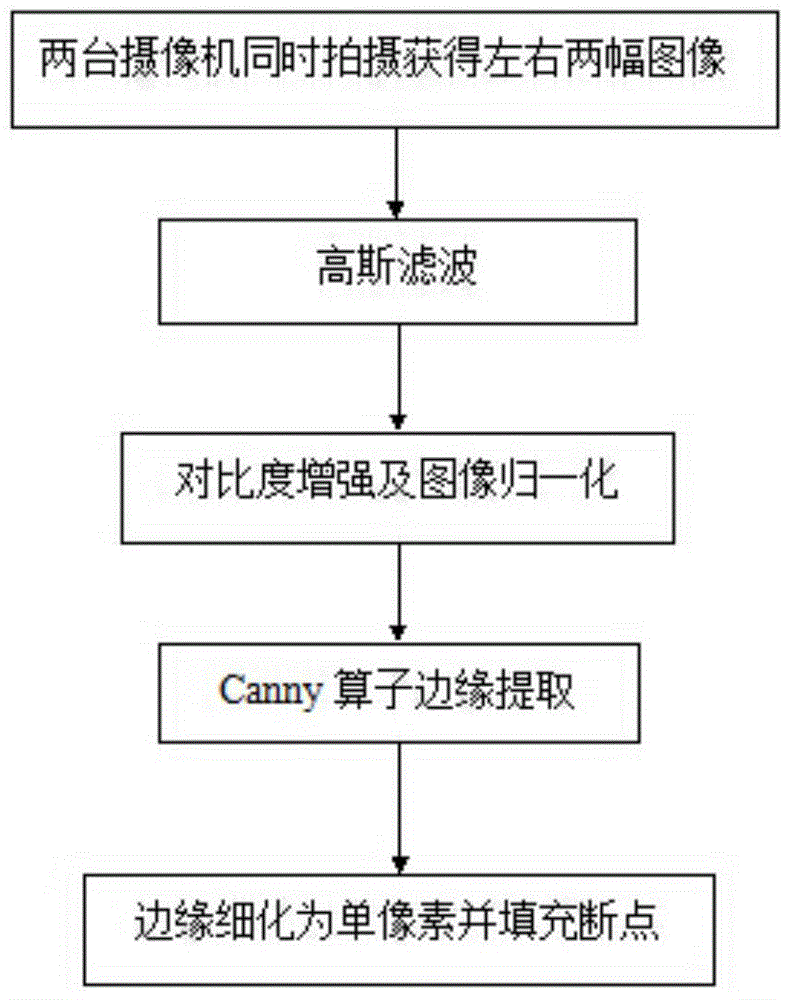

[0018] (2) Image acquisition and preprocessing. Such as figure 2 , including the following substeps:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com