Remote maintenance system of electrical equipment of aerated concrete production line

A technology of aerated concrete and electrical equipment, applied in the field of remote maintenance system, can solve problems such as increasing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention combines the function of PLC on the basis of VPN, and enables electrical engineers to remotely connect equipment on project sites through a 3G network. Allow electrical engineers to remotely debug and modify on-site programs to solve on-site problems.

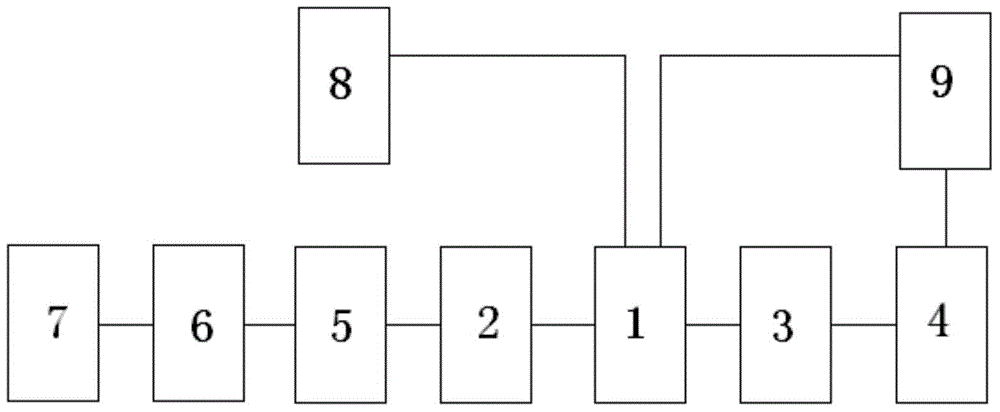

[0014] specific as figure 1 As shown, the present invention includes that the data acquisition unit 3 arranged on the site collects various parameters of the on-site electrical equipment 4 and sends them to the VPN client 1, and the VPN client 1 connects to the 3G router 2 and connects to the VPN server installed in the company through the Internet 5 6. The monitoring center 7 then extracts relevant parameters of the on-site electrical equipment 4 from the VPN server 6 and then performs fault judgment. The VPN client 1 is connected to the PLC controller 9 of the field electrical equipment 4 to realize remote programming of the PLC controller 9 .

[0015] The VPN client 1 is the on-site router, and the WLA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com