Gas pressure flow control valve of sliding-sheet type respirator, and working principle of gas pressure flow control valve

A flow control valve and gas pressure technology, which is applied in the field of ventilators, can solve the problems of high motor noise and large transmission inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

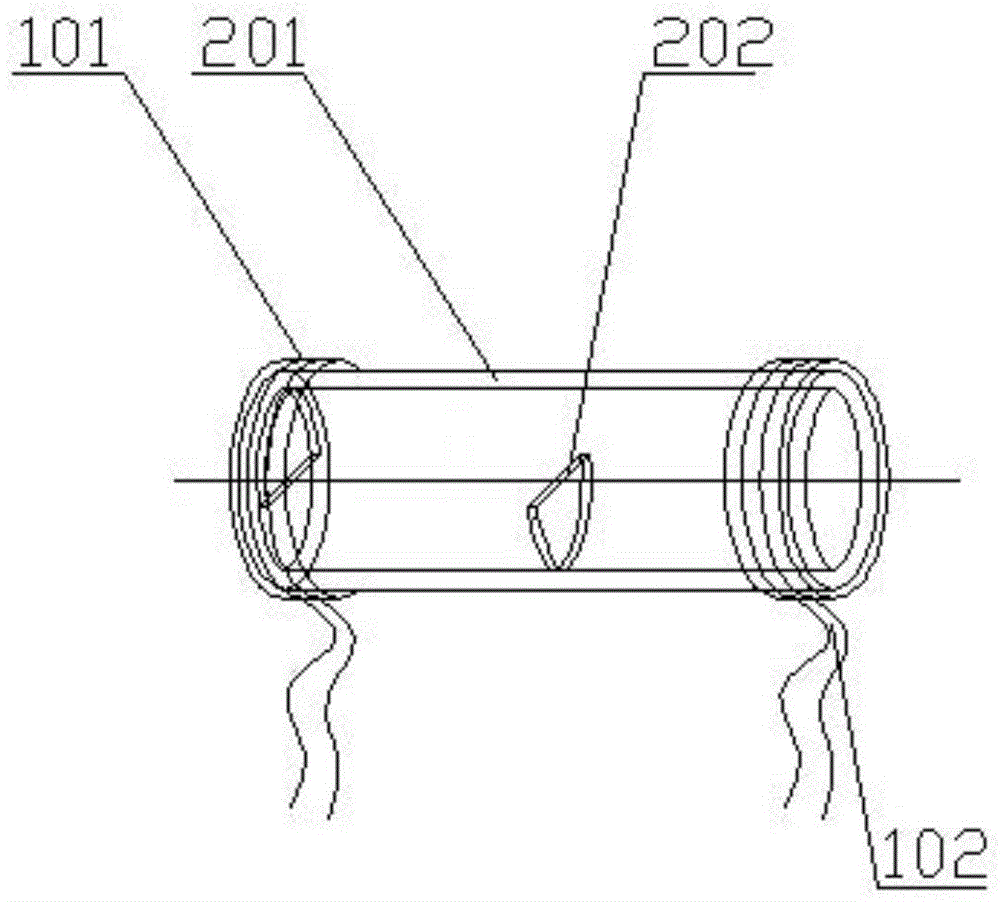

[0035] please combine Figure 1 to Figure 8 As shown, a sliding vane ventilator gas pressure flow control valve of the present invention includes a gas distribution cylinder, a gas distribution fixing piece, and a gas distribution sliding piece, wherein,

[0036] The gas distribution cylinder is a cylinder with a hollow cylindrical structure with one end open and the other end semi-open. The left and right ends of the gas distribution cylinder are respectively wound with several electromagnetic coils, including the left electromagnetic coil and the right electromagnetic coil. There is a blocking piece inside the gas distribution cylinder. The structure of the blocking piece just matches the shape of the opening at the left end of the air distribution cylinder;

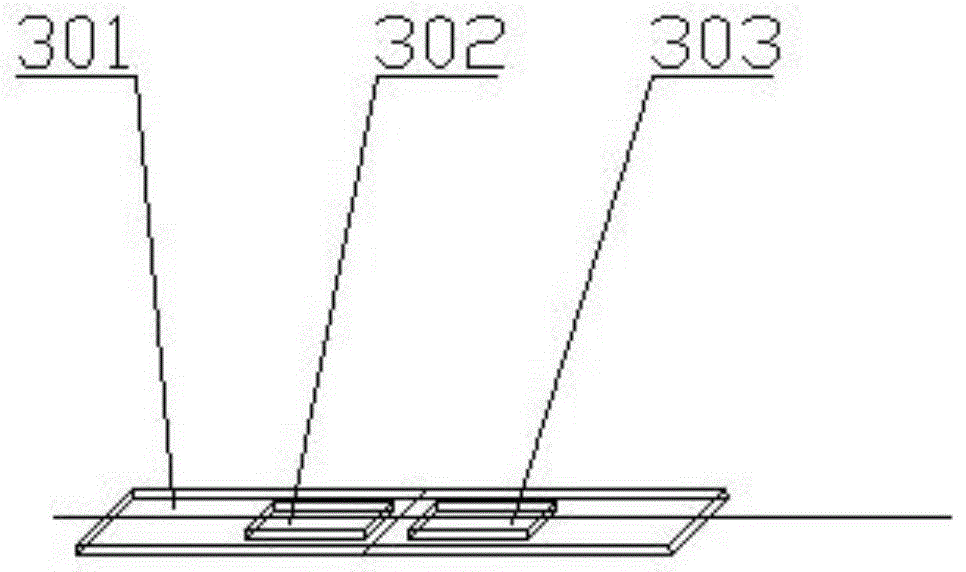

[0037] The gas distribution fixing piece is a rectangular sheet structure, and the gas distribution fixing piece is provided with a left air distribution hole and a right air distribution hole;

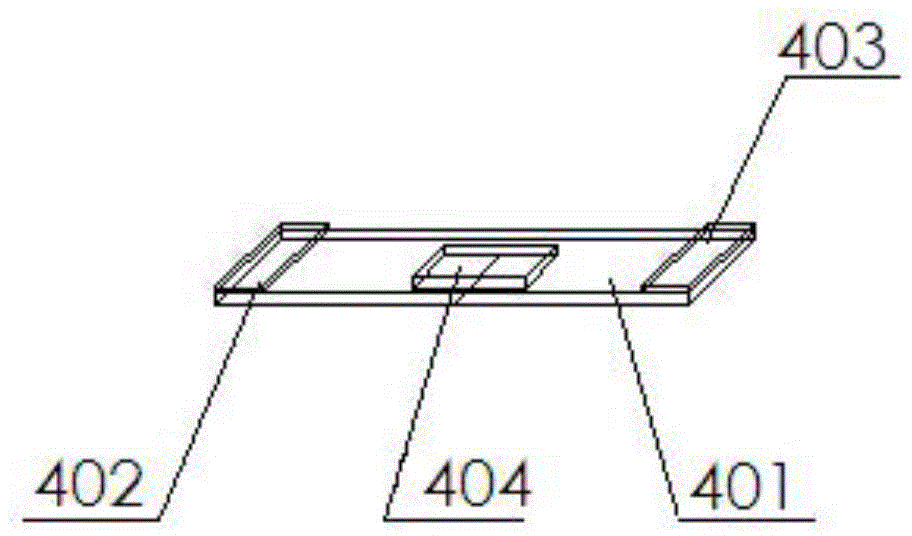

[0038] The air distri...

Embodiment 2

[0052] See Figure 9 As shown, in this embodiment, the basic structure of the gas pressure and flow control valve of the sliding vane ventilator is the same as that of Embodiment 1, the difference is that the air distribution cylinder in this embodiment is a fully closed structure at both ends, and it is equipped with The side of the gas cylinder is provided with a breathing connecting pipe 1000, a high-pressure gas connecting pipe 2000 and an ambient atmosphere connecting pipe 3000. The shape of the gas distribution hole and the left and right gas distribution holes can be circular, oval, square, rhombus or other arbitrary shapes, and can be adjusted according to different The above-mentioned different structures and shapes can also achieve the technical effect as in the first embodiment. Since the specific implementation is the same as that in the first embodiment, details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com