Visible light nano composite photocatalysis material and preparation method thereof

A photocatalytic material and composite photocatalytic technology, applied in the field of visible light nanocomposite photocatalytic material AgSbO3/SnO2 and its preparation, can solve the problems of reducing catalyst activity and stability, and achieve the effect of improving stability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

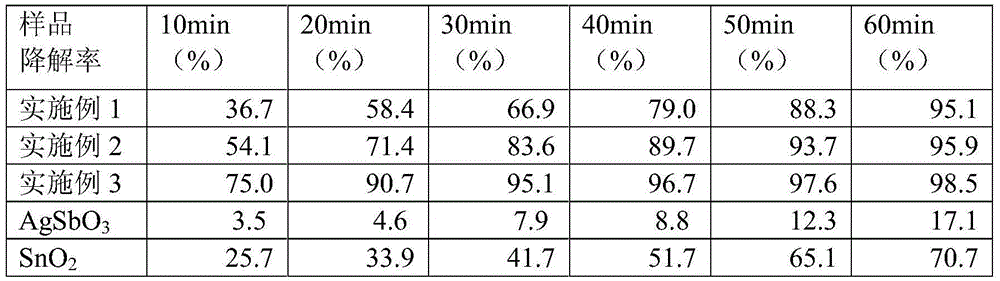

Embodiment 1

[0018] The visible light nanocomposite photocatalytic material of the present invention is made of AgSbO 3 with SnO 2 Composite.

[0019] The specific steps of the preparation method of the visible light nanocomposite photocatalytic material of the present invention are as follows:

[0020] Take 0.02moL AgNO 3 Dissolve in 100mL deionized water, NaSbO 3 with AgNO 3 Mix and stir for 0.5h according to the molar ratio of 1:1, then press Sn(OH) 4 : AgNO 3 =0.3:1 molar ratio to add Sn(OH) 4 , stirred and mixed for 1h, poured into the reaction kettle, reacted at 150°C for 20 hours, and dried by centrifugation to obtain AgSbO 3 / SnO 2 Composite photocatalytic nanomaterials.

[0021] The Sn(OH) 4 The preparation method is as follows:

[0022] SnCl 4 ·5H 2 O is dissolved in dilute hydrochloric acid with a pH between 1 and 2, and dilute ammonia water with a concentration of 0.5 mol / L is gradually and slowly added dropwise, SnCl 4 ·5H 2 The molar ratio of O to dilute ammoni...

Embodiment 2

[0024] The visible light nanocomposite photocatalytic material of the present invention is made of AgSbO 3 with SnO 2 Composite.

[0025] The specific steps of the preparation method of the visible light nanocomposite photocatalytic material of the present invention are as follows:

[0026] Take 0.02moL AgNO 3 Dissolve in 100mL deionized water, NaSbO 3 with AgNO 3 Mix and stir for 2 hours according to the molar ratio of 1.3:1, and then press Sn(OH) 4 : AgNO 3 =0.4:1 molar ratio to add Sn(OH) 4 , stirred and mixed for 3 hours, poured into the reaction kettle, reacted for 10 hours at 200°C, and dried by centrifugation to obtain AgSbO 3 / SnO 2 Composite photocatalytic nanomaterials.

[0027] The Sn(OH) 4 The preparation method is as follows:

[0028] SnCl 4 ·5H 2 O is dissolved in dilute hydrochloric acid with a pH between 1 and 2, and dilute ammonia water with a concentration of 0.5 mol / L is gradually and slowly added dropwise, SnCl 4 ·5H 2 The molar ratio of O to...

Embodiment 3

[0030] The visible light nanocomposite photocatalytic material of the present invention is made of AgSbO 3 with SnO 2 Composite.

[0031] The specific steps of the preparation method of the visible light nanocomposite photocatalytic material of the present invention are as follows:

[0032] Take 0.02moL AgNO 3 Dissolve in 100mL deionized water, NaSbO 3 with AgNO 3 Mix and stir for 1h according to the molar ratio of 1.1:1, then press Sn(OH) 4 : AgNO 3 =0.6:1 molar ratio to add Sn(OH) 4 , stirred and mixed for 2 hours, poured into the reaction kettle, reacted for 15 hours at 180°C, and dried by centrifugation to obtain AgSbO 3 / SnO 2 Composite photocatalytic nanomaterials.

[0033] The Sn(OH) 4 The preparation method is as follows:

[0034] SnCl 4 ·5H 2 O is dissolved in dilute hydrochloric acid with a pH between 1 and 2, and dilute ammonia water with a concentration of 0.5 mol / L is gradually and slowly added dropwise, SnCl 4·5H 2 The molar ratio of O to dilute am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com