Floating agglomeration electromagnetic concentrating equipment

A technology of electromagnetic beneficiation and flotation agglomeration, applied in the field of mineral beneficiation and processing, can solve the problems of low concentrate grade, black tailings, unstable overflow, etc., and achieve low cost, fast separation speed and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

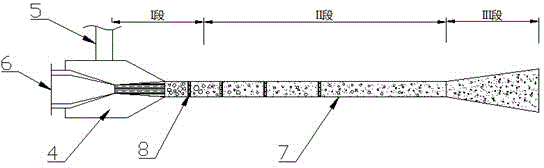

[0038] As an improvement of Embodiment 1, a plurality of foam shearing devices 8 can be arranged on the channel of the second section of the bubble delivery pipe 7, which are mainly used to shear the initially generated micro-nano bubbles, thereby obtaining more nano-bubbles and making the micro-nano bubbles The size of bubbles and nano-bubbles is more uniform, preventing the merger between micro-bubbles and nano-bubbles, which is conducive to the smooth progress of "floc" floating agglomeration; in this embodiment, the shearing device 8 can be multiple radially located There is a filter screen with irregular pores in the segment to block and shear the air bubbles with larger diameters to form more nano-bubbles, or the foam shearing device 8 can use multiple friction plates with irregular lines , can also play the role of shearing the large bubbles in the water flow to form more nano-bubbles; or, a mace-shaped barrier can also be used to shear and block the bubbles. There are ...

Embodiment 3

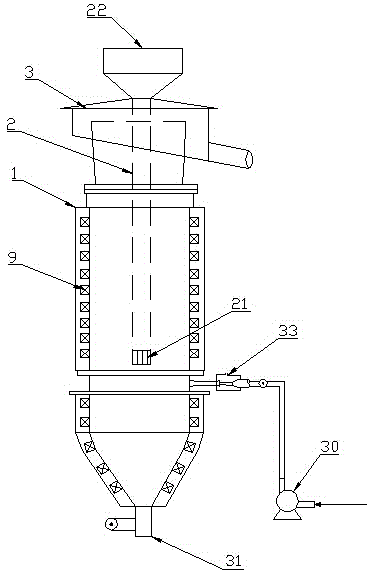

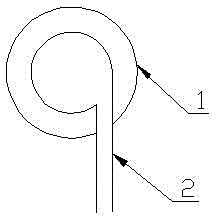

[0040] As a further improvement, the present embodiment divides the column body 1 into a vertical upper section and a conical lower section, and multiple groups of helical tube excitation coils 9 of the alternating magnetic field generator are wound around the periphery of these two sections, which can be used in the vertical upper section and the conical lower section. The lower section of the cone produces a penetrating uneven alternating magnetic field to improve the separation effect. The lower section of the cone is more conducive to collecting the magnetic mineral particles after flotation, and they are more thoroughly discharged from the concentrate discharge port or the connected concentrate discharge pipe. Further, the column body 1 can also be set as a matching structure between the inner wall and the outer wall, and a closed space 10 is formed between the inner wall and the outer wall for assembling the solenoid excitation coil 9 .

[0041] Further, the air inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com