Through-connection box for full-automatic soft type endoscope cleaning machine

A transfer box and washing machine technology, applied in sanitary equipment for toilets, cleaning methods using liquids, dryers, etc., can solve problems such as high labor intensity, poor traceability, and potential safety hazards, and avoid secondary Pollution, avoid bump damage, and ensure the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

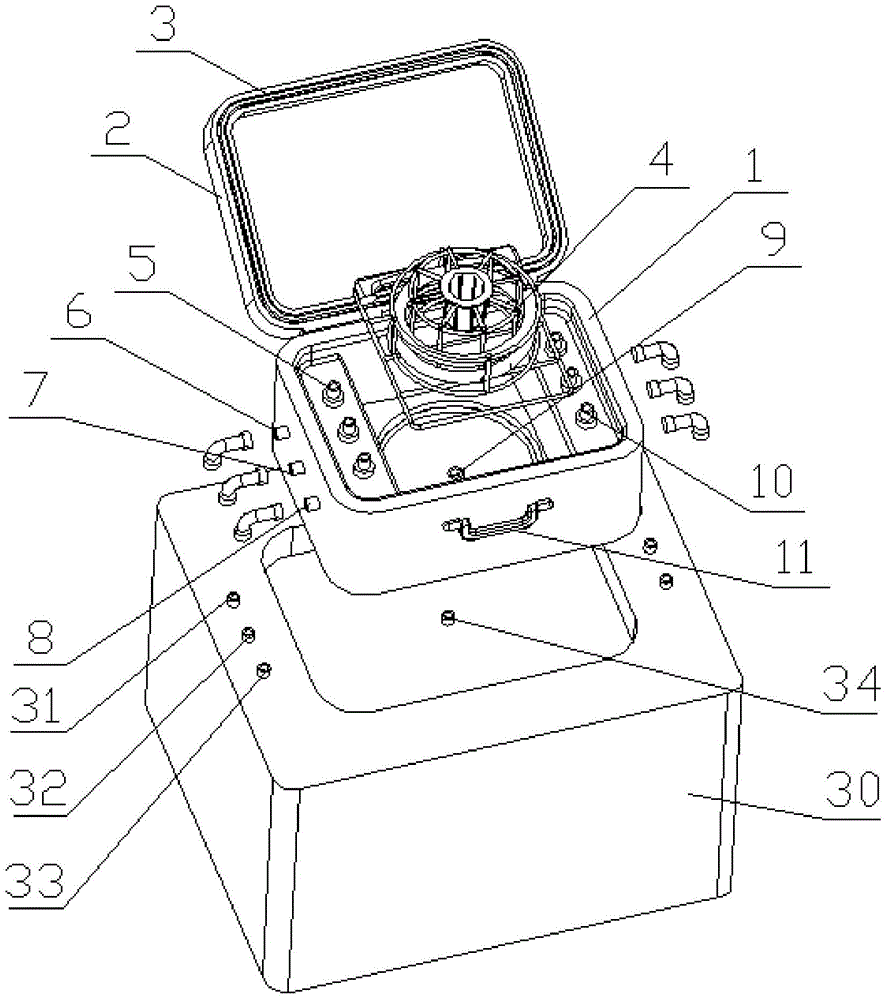

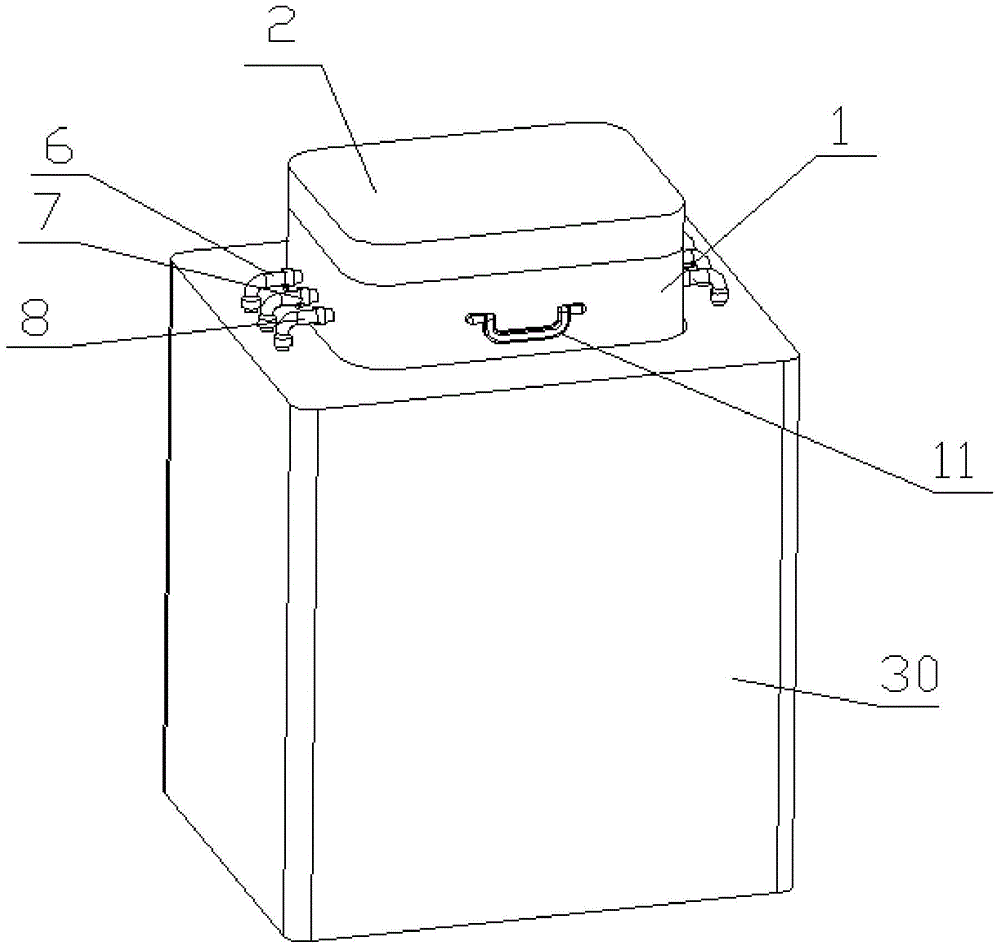

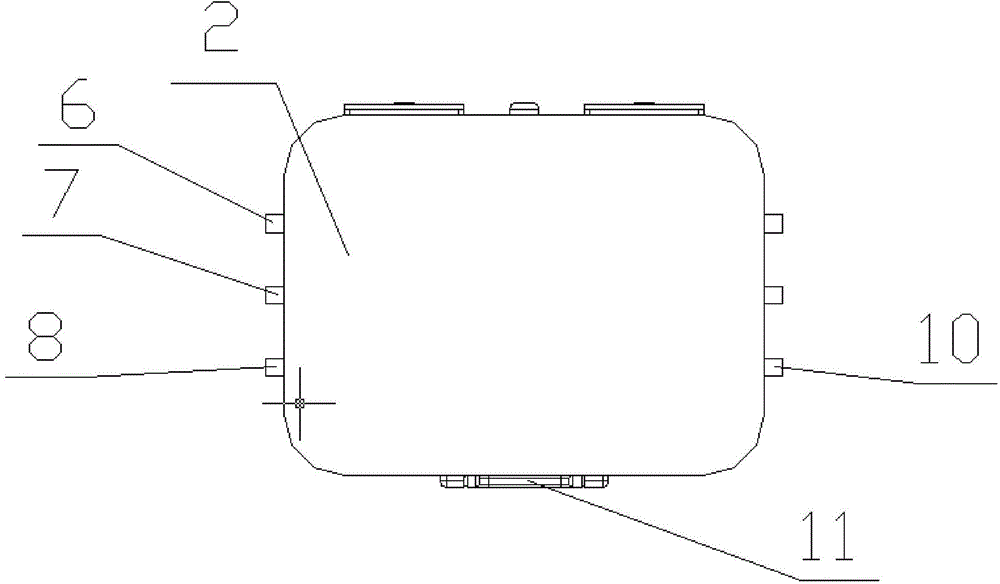

[0021] Such as Figure 1 to Figure 3 As shown, the first specific implementation of the present invention is: an adapter box for a fully automatic soft endoscope cleaning machine, including a box body 1 and a box cover 2, between the box body 1 and the box cover 2. A sealing strip 3 is arranged between the box body 1 and the box cover 2. The box body 1 and the box cover 2 are connected by a lock. The box cover 2 can be buckled on the box body 1, and can keep the adapter box sealed from the outside after being buckled. The body 1 and the box cover 2 can also be connected by hinges or other structures, as long as the connection can ensure that the adapter box remains airtight with respect to the outside world. The shape and size of the adapter box are the same as those of the fully automatic soft endoscope. The inner cavity of the cleaning machine 30 is matched. In this embodiment, the transfer box adopts a square structure, which can be placed in the inner cavity of the automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com