Dustless low-noise construction waste moving crushing station

A construction waste and mobile crushing technology, which is applied in construction waste recycling, chemical instruments and methods, solid waste removal, etc., to achieve the effect of convenient on-site construction and unimpeded convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

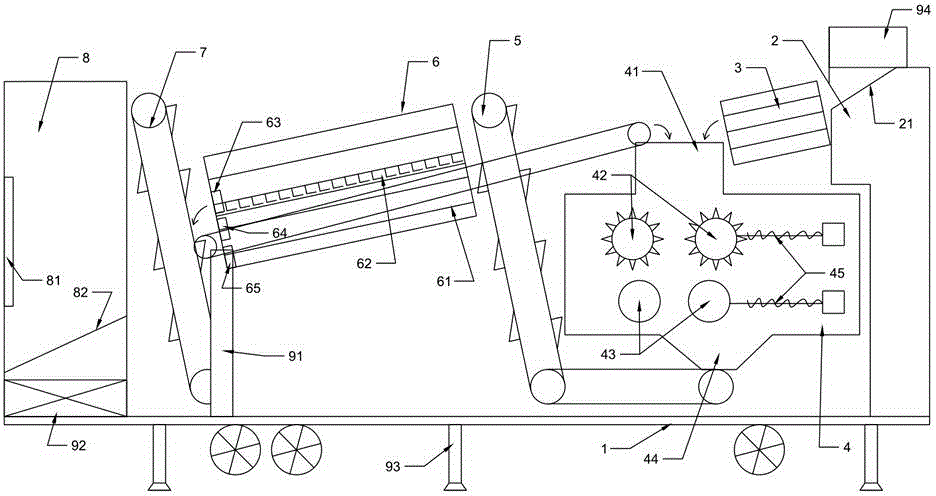

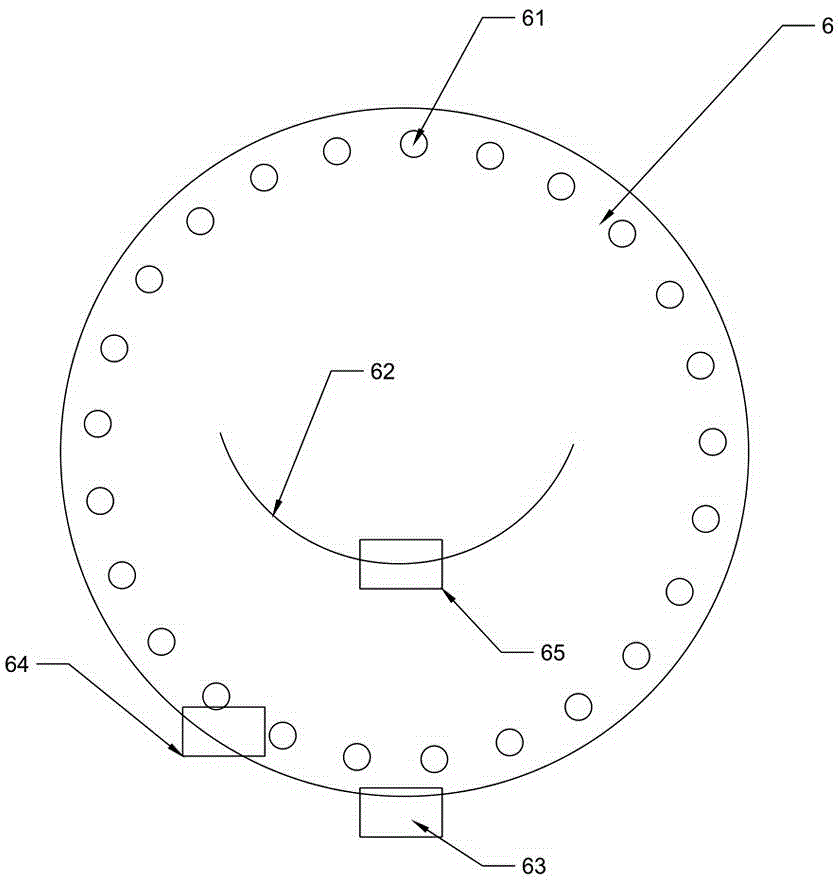

[0019] The present invention newly proposes a dust-free and low-noise mobile crushing station for construction waste, which is a composite processing device that is moved to the old building area by a trailer. Its structural features are as follows: figure 1 As shown, it includes raw material bin 2, rolling sorting feeder 3, combined roller crusher, first chain bucket elevator 5, trommel screen 6, second chain bucket Elevator 7 and finished barrel 8. From the detailed structure of each component, the raw material bin 2 is a detachable frame and the bottom is provided with an inclined bottom plate 21 that guides the material toward the rolling sorting feeder. Most of the urban roads have traffic re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com