A high-speed gantry machine

A gantry machine and high-speed technology, which is applied in the direction of packaging/bundling items, packaging, and web rotary wrapping, etc. It can solve the problems of low packaging efficiency, slow winding speed of packaging film, and low equipment efficiency, and achieve enhanced strength and improved stability. Sex and safety, enhanced durability and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

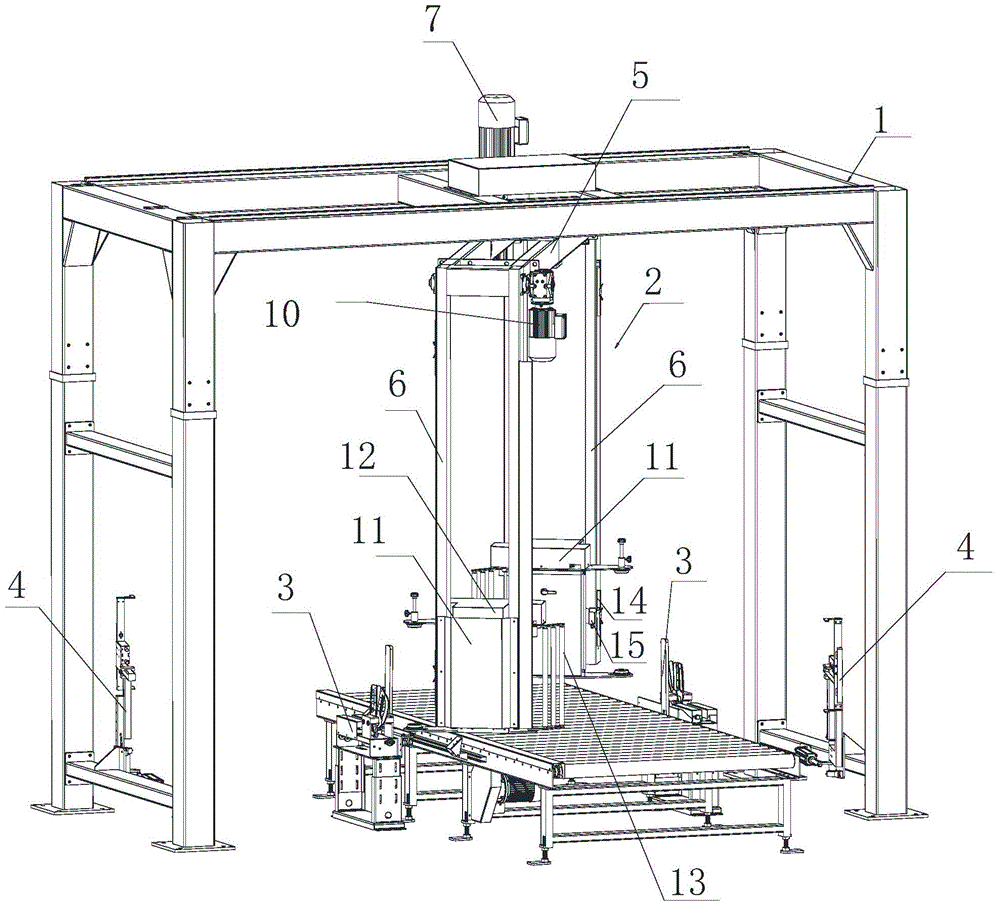

[0017] At first introduce the concrete mechanism of the present invention:

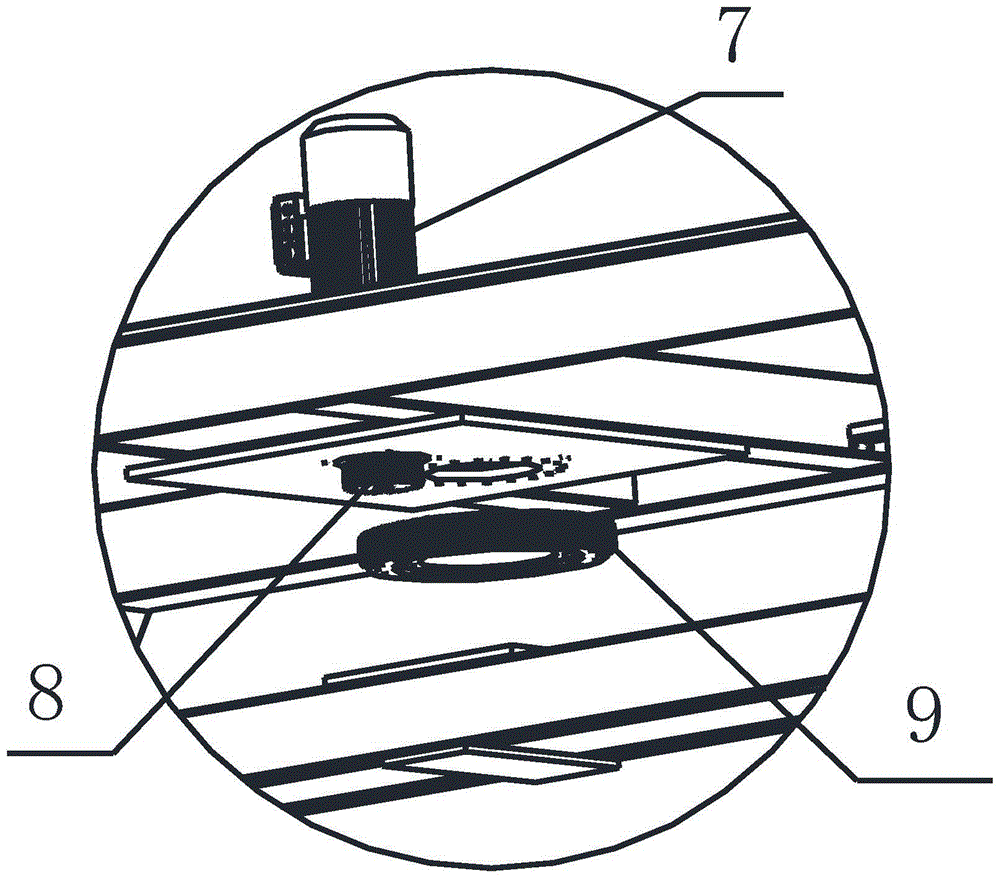

[0018] The present invention comprises a gantry 1 located on the cargo conveying line, a swing arm winding device 2 located on the gantry 1; both sides of the cargo conveying line are provided with a filming mechanism 3 for coating the cargo; both sides of the gantry are provided with The film breaking mechanism 4 that breaks the film and the tail of the cut packaging film is hot glued to the wrapped packaging film; the spiral arm winding device 2 includes a cross arm 5 and a cantilever 6 fixed vertically to the two ends of the cross arm 5; There is a mold base assembly that can reciprocate up and down along the cantilever 6 under the drive of the mold base drive assembly and is used to place the film; the structure of the cantilever 6 is an H-shaped cantilever 6 and is symmetrically arranged; the top of the gantry 1 is equipped with a high-speed The winding drive assembly is used to drive the cross a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com