Photosensitive resin composition and application thereof in three-dimensional printing

A photosensitive resin and composition technology, applied in the chemical industry, can solve the problems of high bonding strength, slow curing speed, etc., and achieve high mechanical strength and dimensional stability, low cost, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

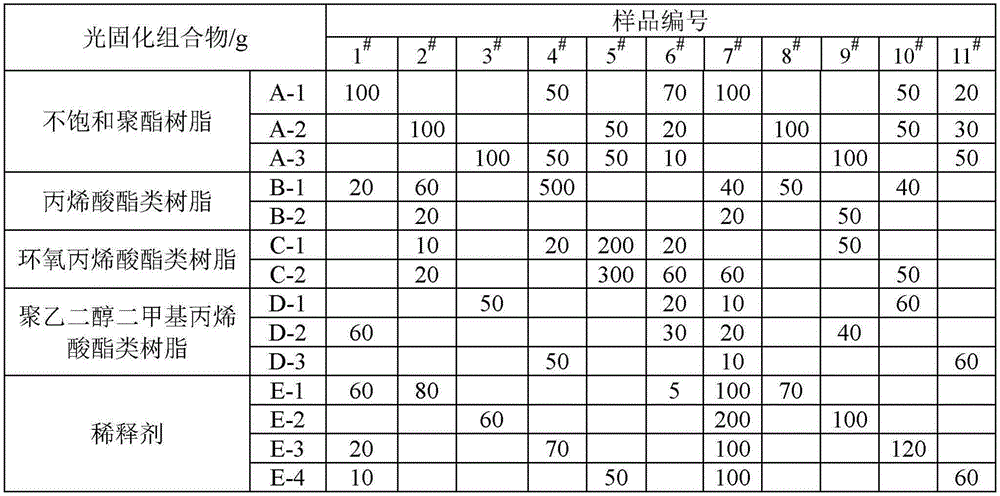

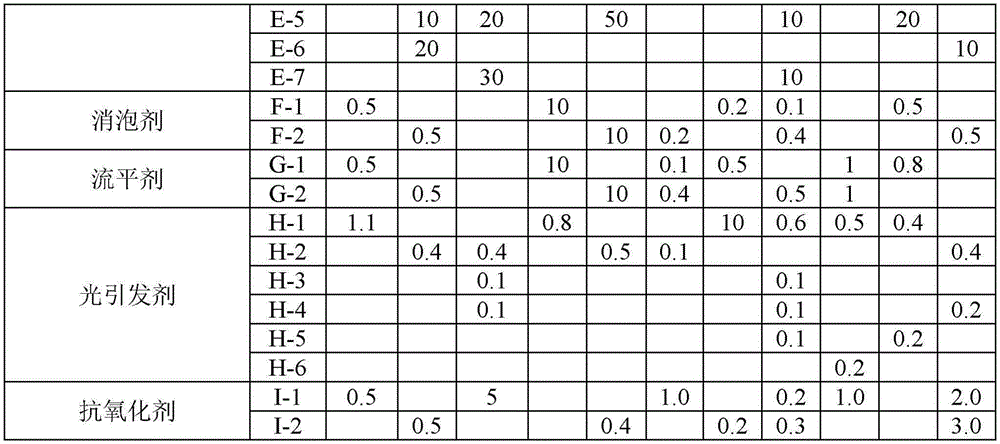

[0080] Example 1 Sample 1 # ~Sample 11 # preparation of

[0081] The preparation steps are as follows: an appropriate amount of unsaturated polyester resin, acrylate resin, acrylate resin, epoxy acrylate resin, polyethylene glycol dimethacrylate resin, diluent, defoamer, fluid The leveling agent, antioxidant and photoinitiator are mixed and heated to 30-100 degrees, and after stirring and mixing evenly, a light yellow viscous liquid is obtained, which is the photosensitive resin composition sample described in this application.

[0082] The relationship between the sample number and the type and proportion of each component is shown in Table 1.

[0083] Table 1

[0084]

[0085]

Embodiment 2

[0086] Application of Embodiment 2 in 3D printer

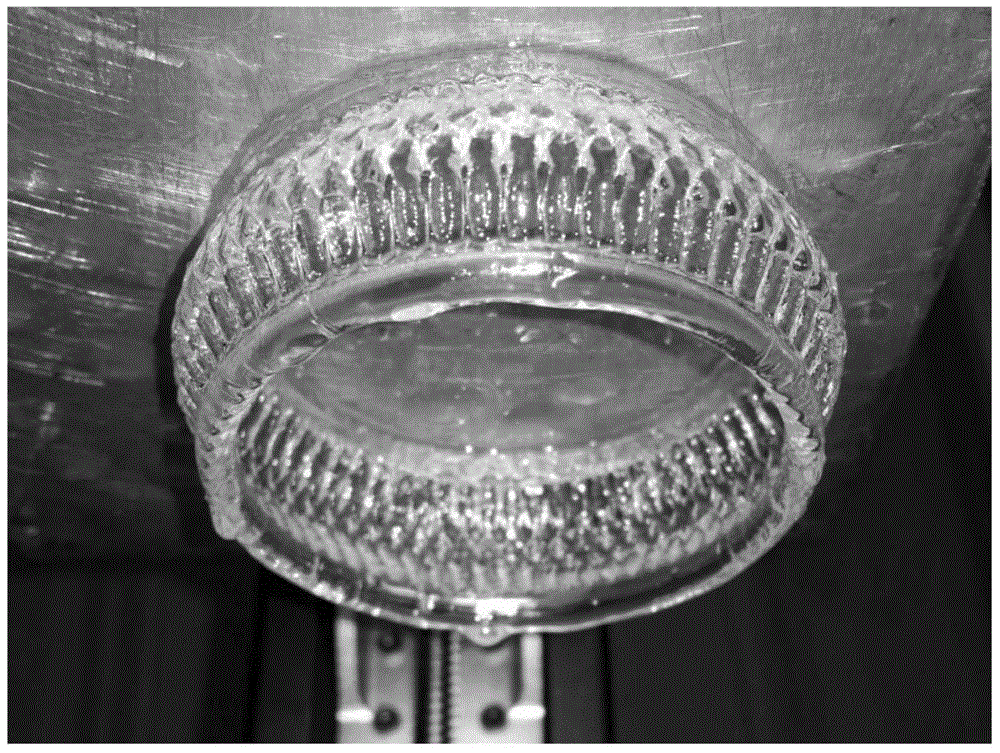

[0087] The sample 1 obtained in embodiment 1 was respectively # ~Sample 11 # Imported into the 405nm 3D printer produced by Formlabs in the United States, through computer modeling, composition and printing, the resulting parts are exquisite. Take sample 1 # The obtained part is a typical representative, and its optical photos are as follows figure 1 shown, sample 2 # ~Sample 11 # The obtained parts and samples 1 # The obtained parts are similar, indicating that the photosensitive resin composition provided by the present application can be successfully used in commercial 3D printers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com