Electromagnetic damping shock absorber for vehicle suspension

An electromagnetic damping, automotive suspension technology, applied in springs/shock absorbers, magnetic springs, springs, etc., can solve the problem that the shock absorption effect cannot meet the full active suspension system technology of the automotive suspension system, and there is no semi-active suspension system. and other problems, to achieve the effect of improving comfort and handling stability, simple and practical structure, and improving design requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

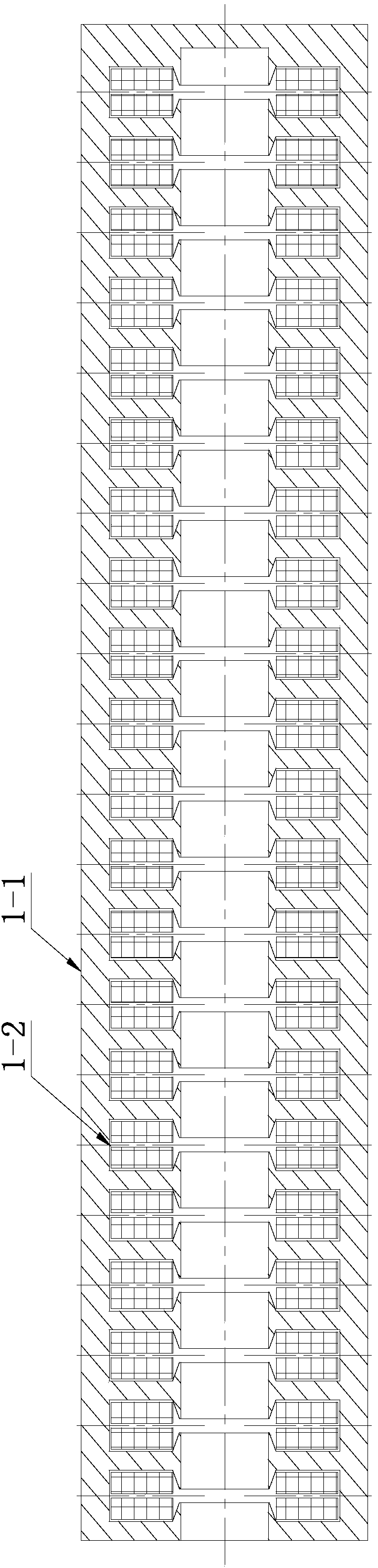

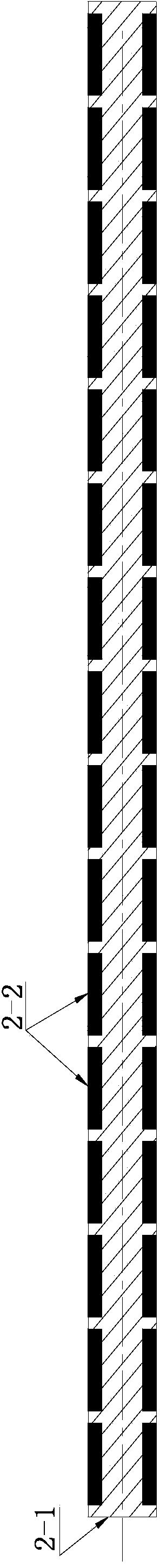

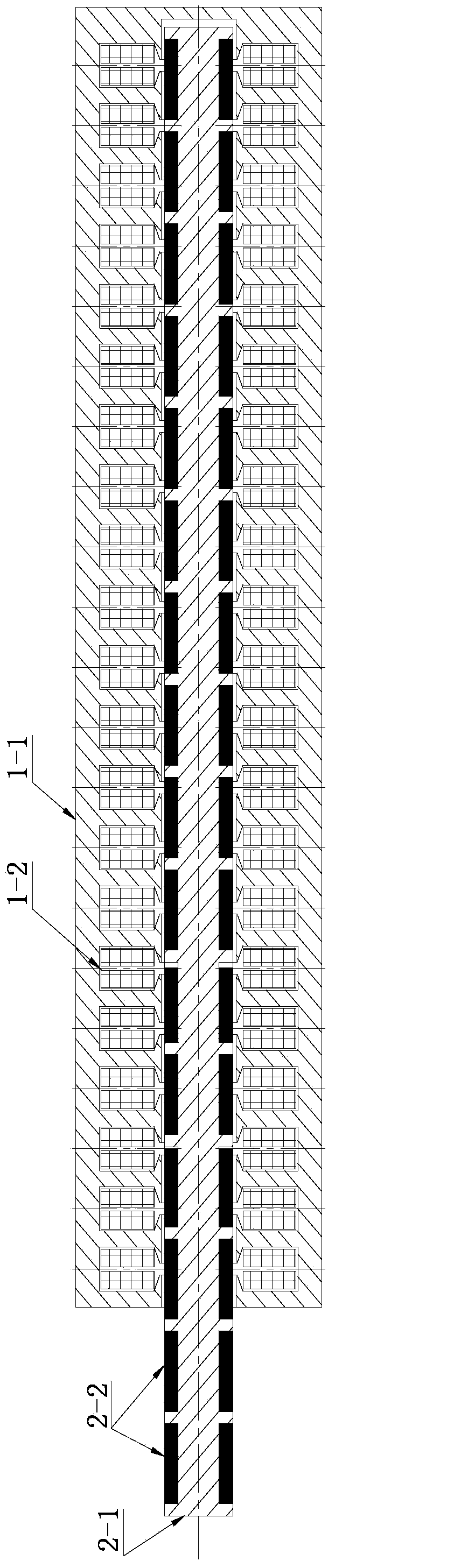

[0017] Such as Figure 1 to Figure 3 As shown, the electromagnetic damping shock absorber used for automobile suspension of the present invention includes an outer cylinder 1 and a piston rod 2, and the outer cylinder 1 includes a stator core 1-1 and a pie-type three-phase winding 1-2, and the pie-type three-phase winding 1-2 is fixedly connected to the inside of the piston chamber of the stator core 1-1 by a spiral layout method. Piston rod 2 includes mover iron core 2-1 and multi-segment annular winding 2-2, multi-segment annular winding 2-2 is fixedly connected and sleeved on mover iron core 2-1 in sequence at equal intervals, and each annular winding 2-2 is connected in parallel and connected to the power supply respectively. The length of the piston rod 2 is greater than that of the outer cylinder 1, and the piston rod 2 is inserted into the cavity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com