Bogie hearth thermal treatment furnace with adjustable heating space

A heating space and heat treatment furnace technology, applied in the direction of lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of affecting the heat treatment effect, low heat treatment efficiency, long heating time, etc., to achieve shortened heating time, high heat treatment efficiency, saving fuel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

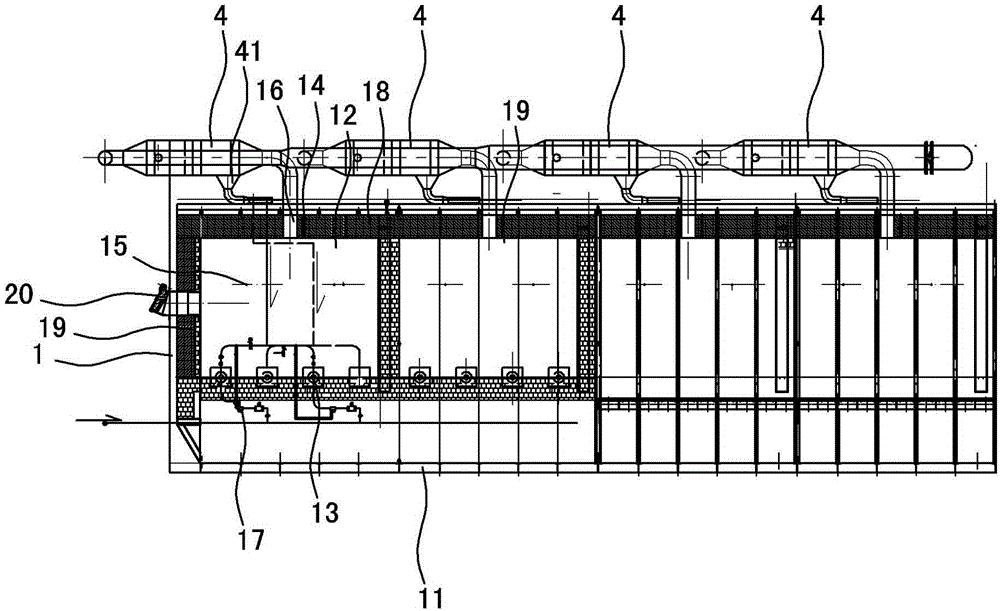

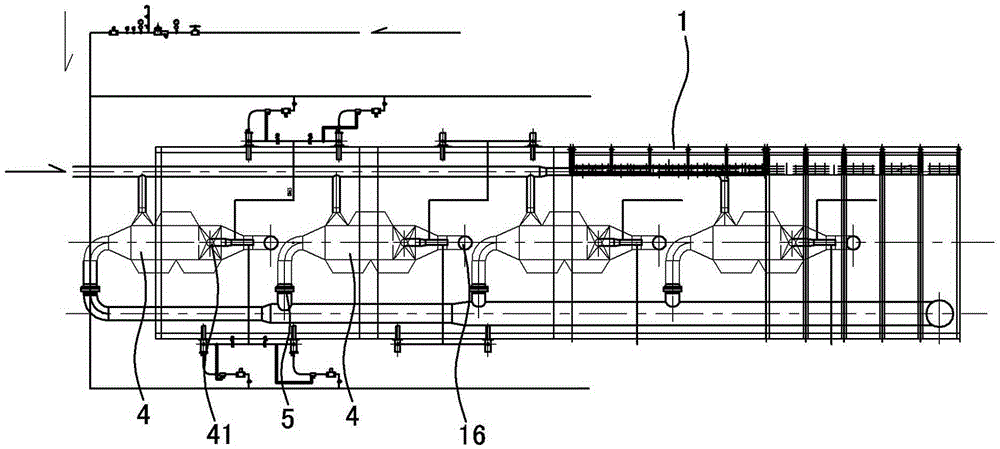

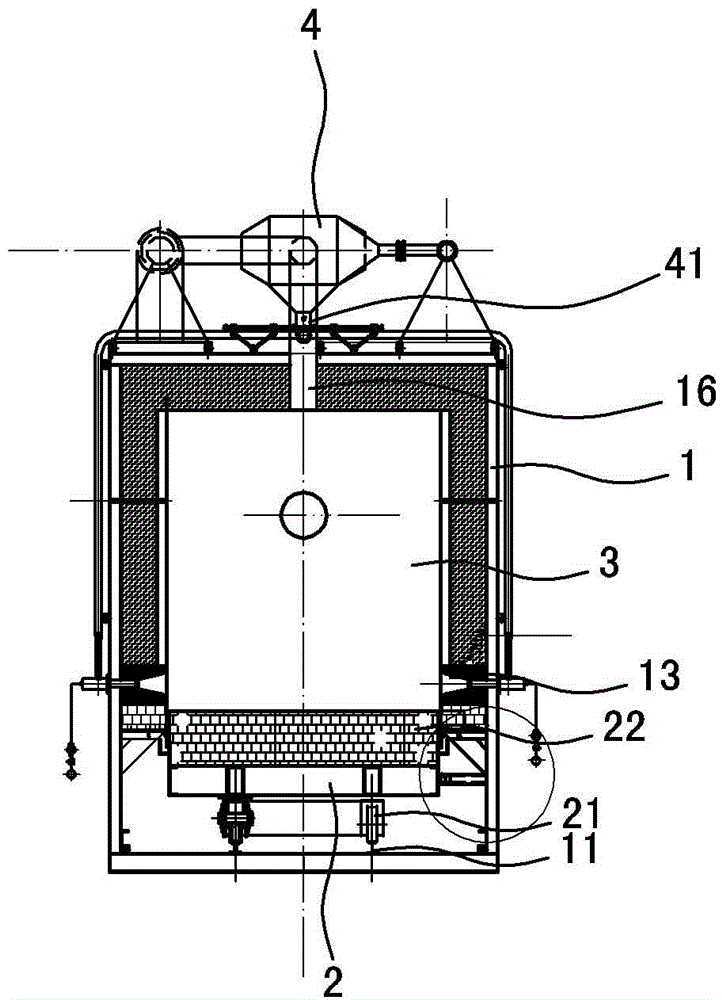

[0014] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, it includes a furnace body 1 and a movable trolley 2 installed on the lower rail 11 of the furnace body 1 through wheels 21, and a platform is respectively provided on each side wall of the furnace body 1 and each side wall of the movable trolley 2. The movable sealing mechanism of the side wall of the car, the furnace door 3 is installed in an upright state on the table 22 of the movable trolley 2, and the bottom of the furnace door 3 is provided with at least two inserting columns 23 matched with the table 22 of the movable trolley 2, The table 22 of the movable trolley 2 is longitudinally provided with a plurality of sets of column jacks 24 for the movable mounting column 23 of the furnace door 3 at intervals along the traveling direction of the movable trolley 2. The table top 22 is movably installed with the respective positions of the furnace door 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com