Mud cooling system

A cooling system and mud technology, applied in water shower coolers, wellbore/well components, heat exchange equipment, etc., can solve the problems of slow cooling efficiency and troublesome implementation, and achieve fast cooling efficiency, convenient cooling, and water cooling effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

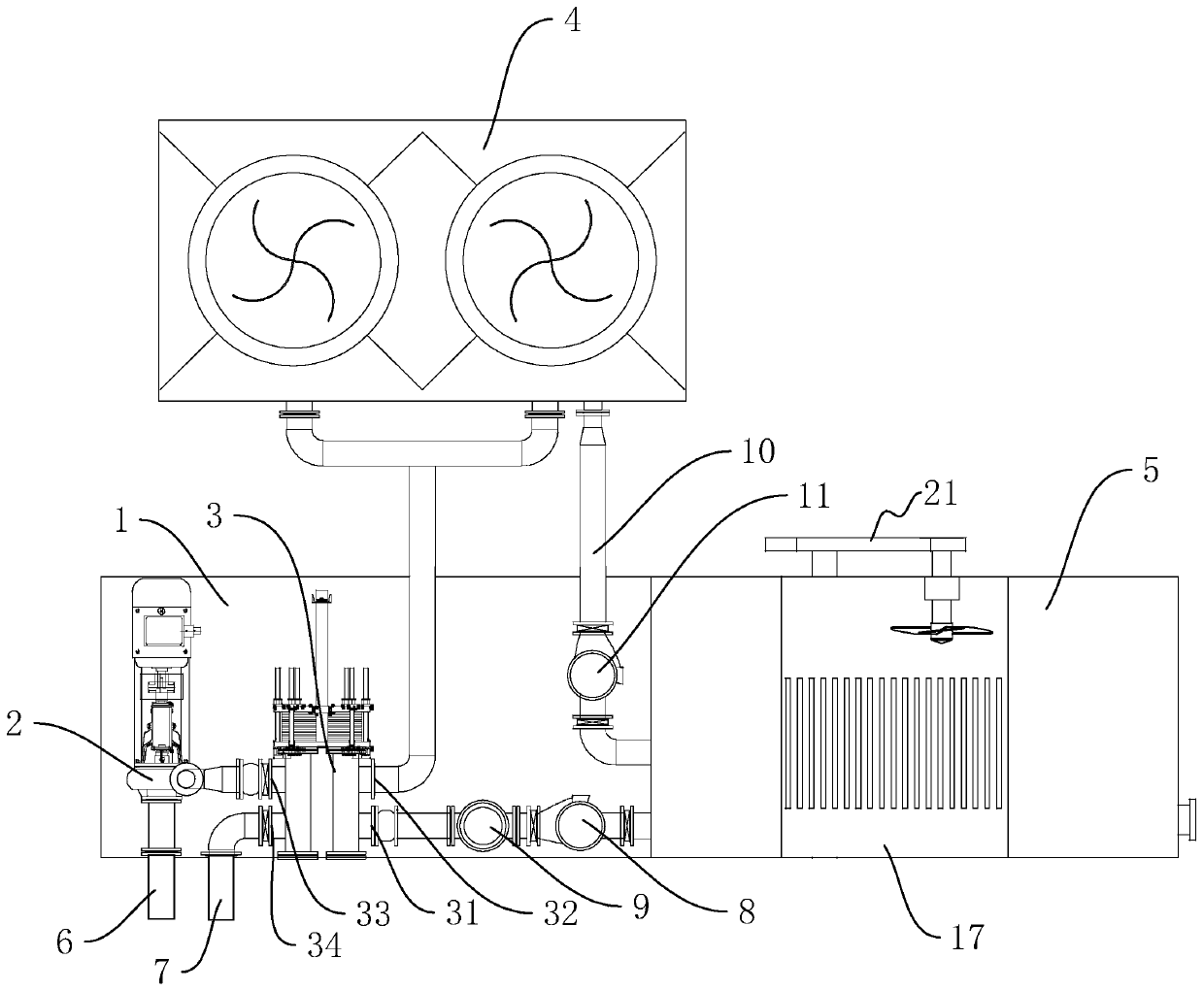

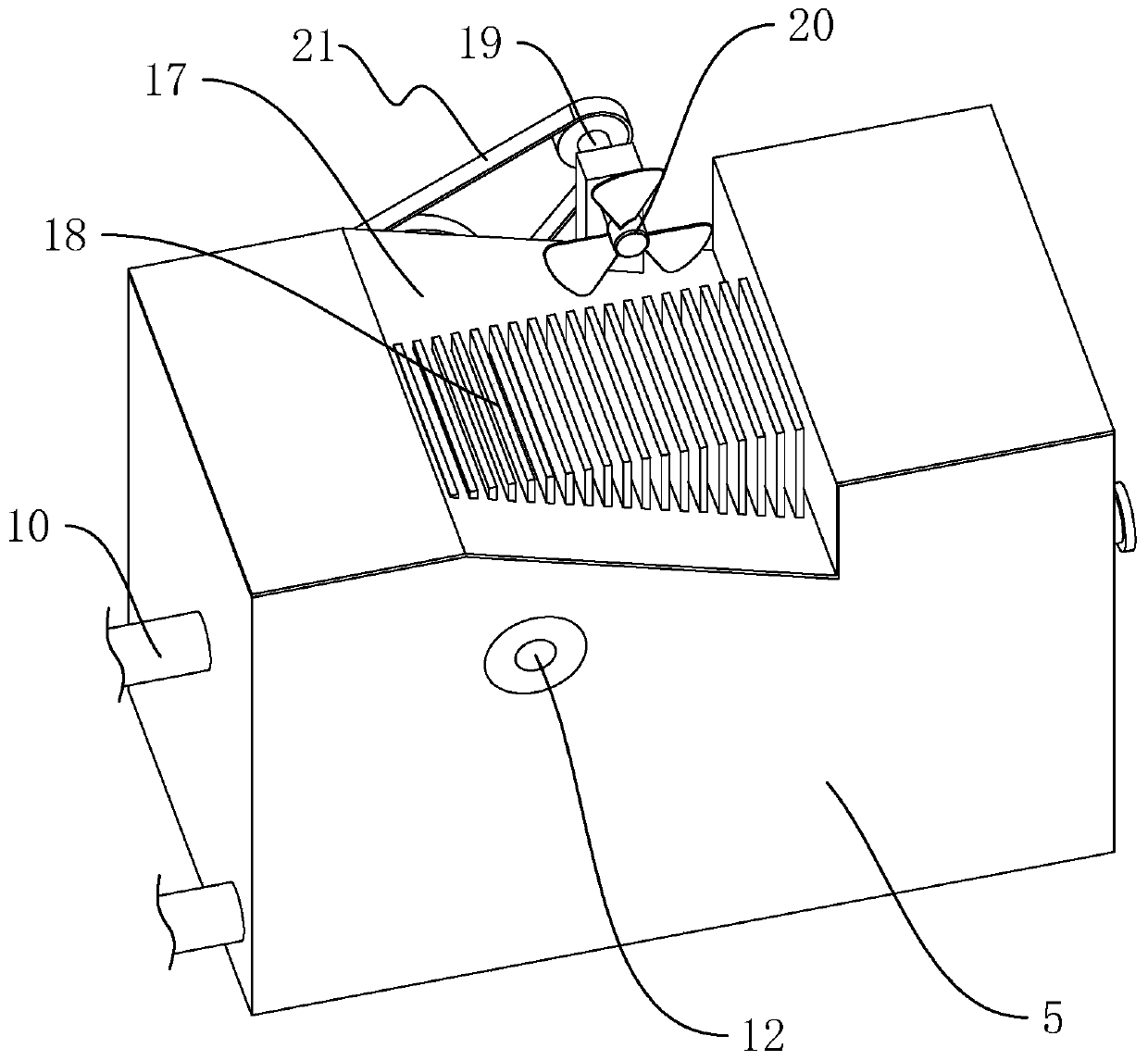

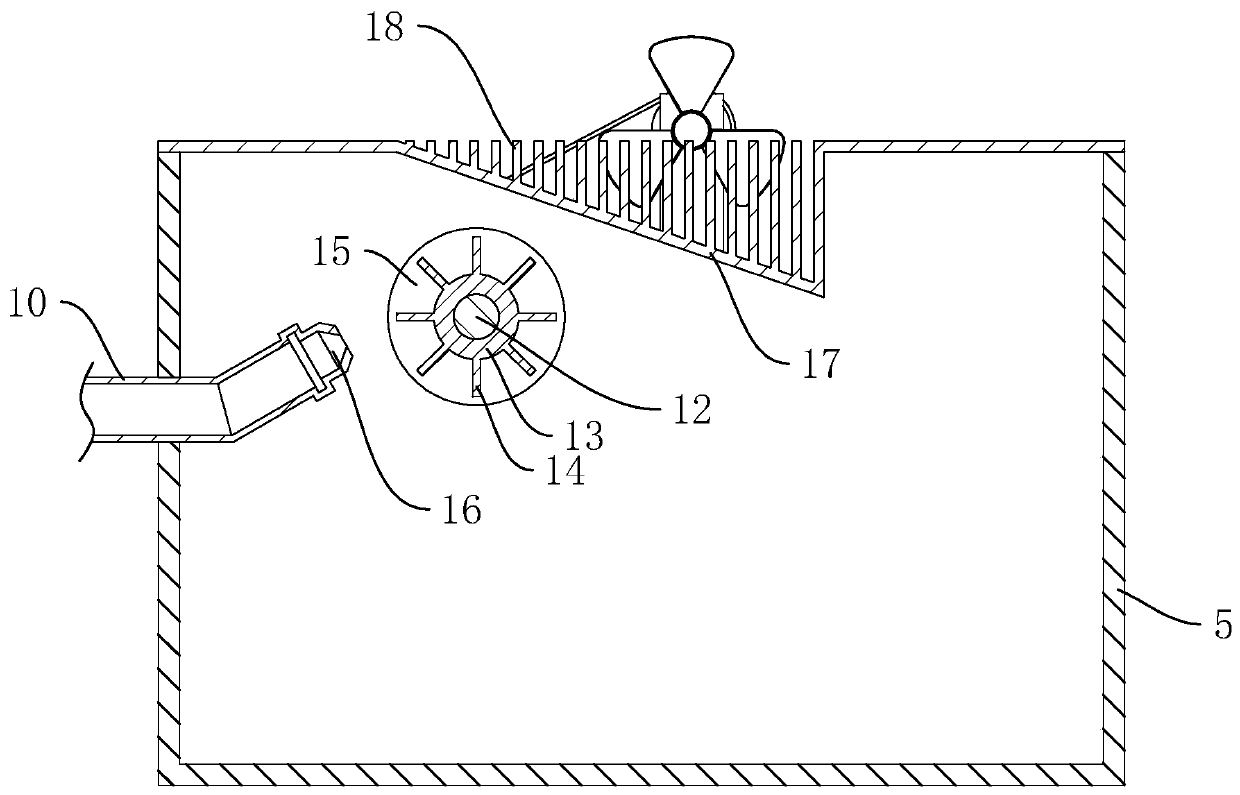

[0035] A mud cooling system such as figure 1 As shown, it includes an installation seat 1, a sand pump 2, a plate heat exchanger 3, a cooling water tower 4 and a water tank 5. Both the sand pump 2 and the plate heat exchanger 3 are located on the mounting base 1, and the water tank 5 is fixedly connected to the side of the mounting base 1. The plate heat exchanger 3 is a new type of high-efficiency heat exchanger formed by stacking a series of metal sheets with a certain corrugated shape. Thin rectangular channels are formed between the various plates to form a first fluid channel (not shown) and a second fluid channel (not shown). The first fluid channel is for cooling liquid to flow through, and the second fluid channel is for cooling Fluid passes through and heat is exchanged through the plates. The plate heat exchanger 3 includes a first fluid inlet 31 communicating with the first fluid channel, a first fluid outlet 32 communicating with the first fluid channel and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com