Dry bulk goods terminal bulk goods machinery remote operation system

An operating system and dry bulk cargo technology, applied in the general control system, control/regulation system, program control, etc., can solve the problem of low equipment level, achieve the effect of centralized dispatch control improvement, improvement of working environment, and improvement of modernity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

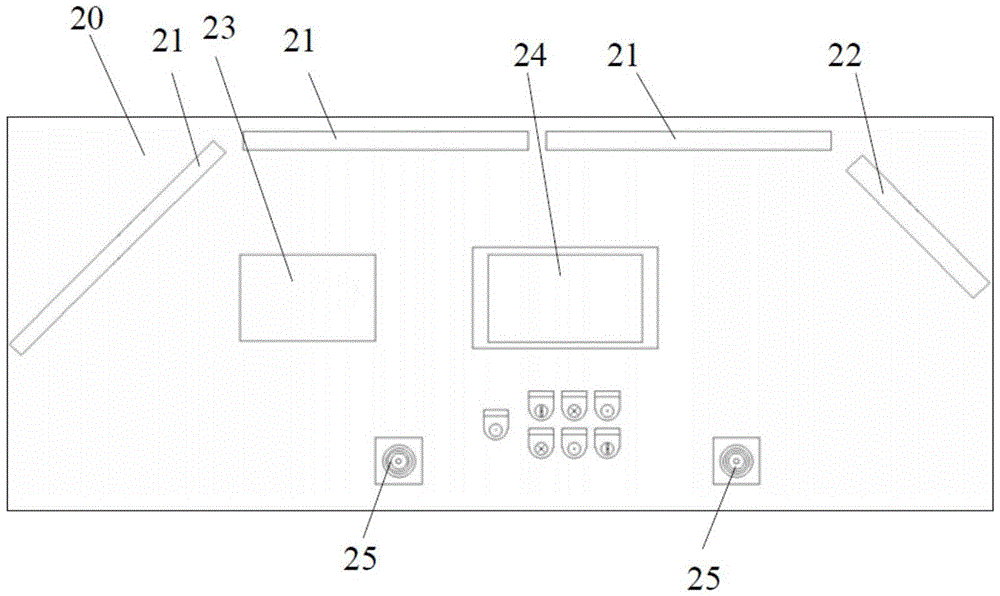

[0060] The invention discloses a remote operating system for bulk cargo machinery in a dry bulk cargo terminal, which is based on industrial bus technology, through the development of PLC and upper computer software, combined with the monitoring of the operation of field equipment by an industrial TV monitoring system, and realizes bulk cargo Remote operation of dock handling equipment. This system liberates the driver of bulk cargo machinery from the closed and narrow driver's cab, allowing the driver to complete various operations in a relatively clean and comfortable central control room.

[0061] The goal of the remote operating system for bulk cargo machinery is to achieve the same operation in the ground control room as in the driver's cab, which mainly includes a control system, RCMS system, CCTV system and operation console. The RCMS system is a large-scale equipment management and monitoring system. The CCTV system is a closed-circuit television monitoring system. T...

Embodiment 2

[0070] The structure of this embodiment is basically the same as that of Embodiment 1, the difference being that nine camera systems are arranged on the reclaimer in the remote operating system of bulk cargo machinery at the dry bulk cargo terminal.

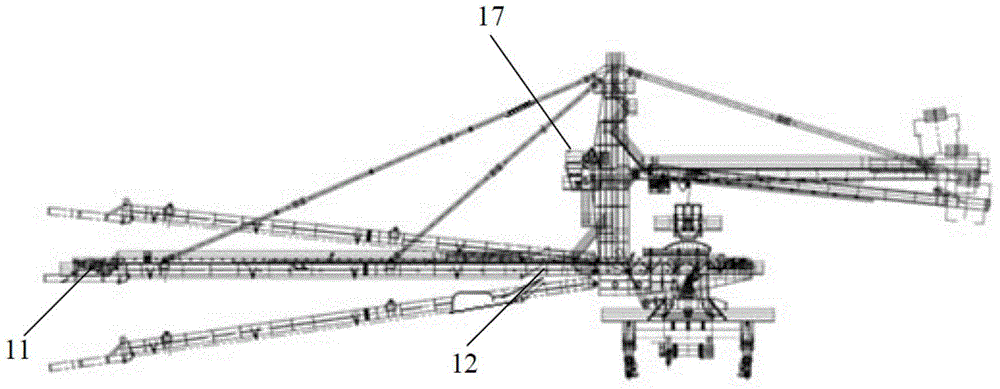

[0071] Figure 4 It is a schematic diagram of nine camera systems arranged on the reclaimer in the remote operating system of the bulk cargo machinery at the dry bulk cargo terminal of the present invention. The first integrated dedicated camera system 31 is installed on the mounting bracket above the front of the bucket wheel, and is used to observe the working state of the bucket wheel and the stacking situation when stacking and reclaiming. The second integrated special-purpose camera system 32 is installed above the driver's cab and is used to observe the situation around the stockyard. The third semi-fixed camera system 33 is installed near the front of the large machine for observing the walking situation of the large vehi...

Embodiment 3

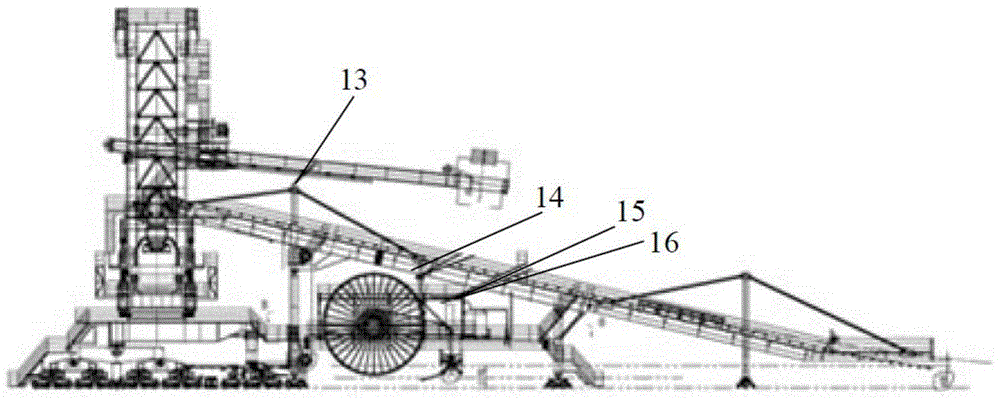

[0073] The structure of this embodiment is basically the same as that of Embodiment 1, the difference being that nine camera systems are arranged on the ship unloader in the remote operating system of bulk cargo machinery at the dry bulk cargo terminal.

[0074] Figure 5 It is a schematic diagram of nine camera systems arranged on the ship unloader in the remote operating system of the dry bulk cargo terminal bulk cargo machinery of the present invention Figure 1 . Figure 6 It is a schematic diagram of nine camera systems arranged on the ship unloader in the remote operating system of the dry bulk cargo terminal bulk cargo machinery of the present invention Figure II . Such as Figure 5 and Figure 6 As shown, the first integrated dedicated camera system 41 is installed on the upper beam of the sea survey door frame, and is used to observe the discharge situation of the grab bucket. The second integrated special-purpose camera system 42 is installed on the turning poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com