Machine vision-based cable on-line detection method

A technology of machine vision and detection method, which is applied in the direction of instruments, computer parts, image data processing, etc., and can solve the problems of unqualified products, immediate stop, missing printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

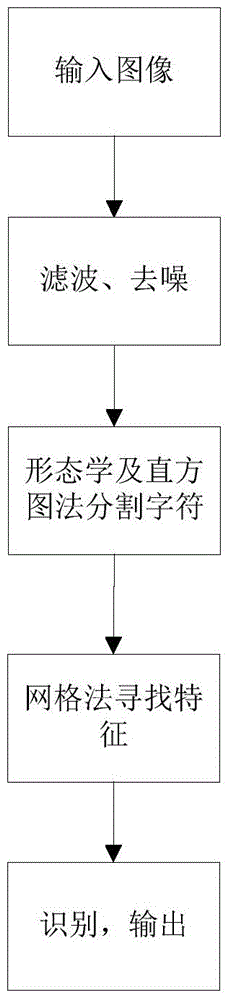

[0043] Below in conjunction with accompanying drawing, the online detection method of cable among the present invention is described in detail:

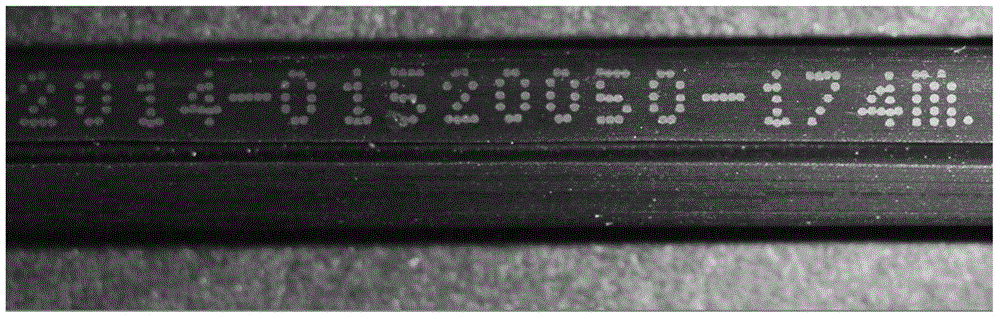

[0044] Step 1: Use a high-speed camera to collect video images of the cable.

[0045] Step 2: Perform anti-shake processing on the video collected in step 1. The principle is based on the matching of feature points and the affine transformation algorithm to obtain each frame of image after de-shaking.

[0046] Step 2-1: Read the previous frame image in the video stream as the reference image, and use the SIFT algorithm to extract scale-invariant feature points;

[0047] Step 2-2: Read the current frame and calculate the feature points, use the affine transformation model to register with the reference image, and use the registered image as the new current frame.

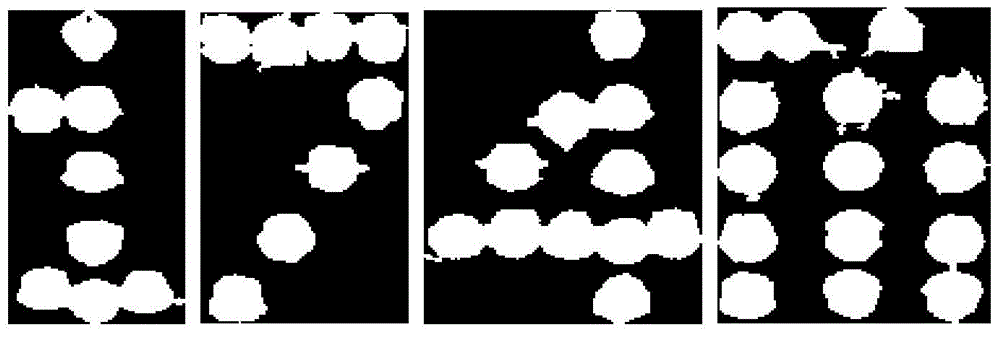

[0048] Step 3: Binarize the image in step 2 according to the preset gray value.

[0049] Step 3-1: The threshold of image binarization adopts Otsu algorithm;

[0050] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com