Display apparatus

A display device and non-display technology, which is applied in the directions of identification devices, instruments, semiconductor devices, etc., can solve the problems of abnormal operation of the circuit part and easy changes in electrical characteristics, and achieve the effect of not easy to operate badly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

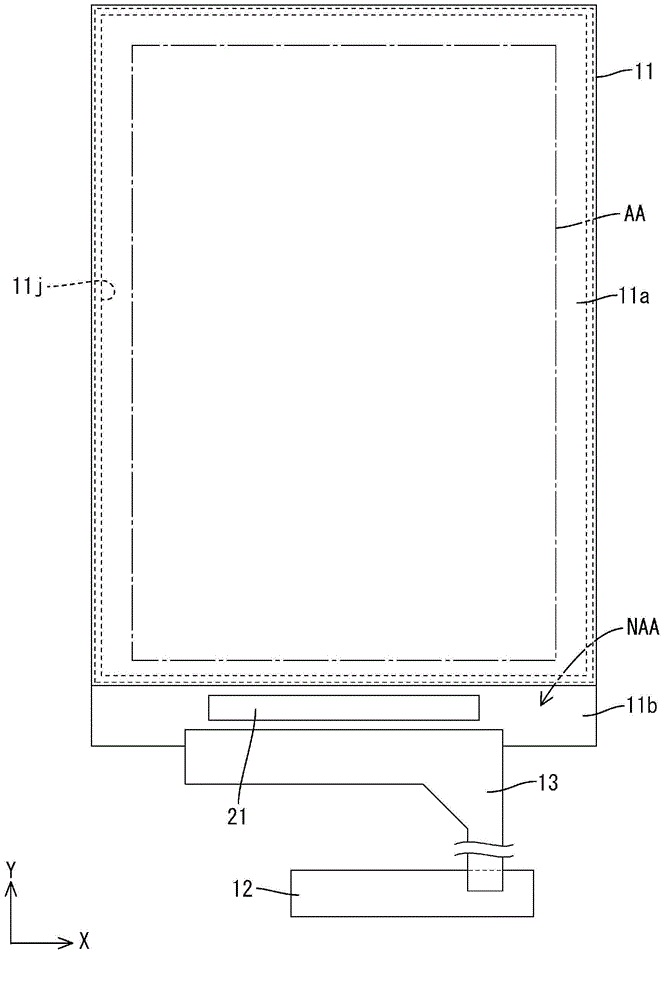

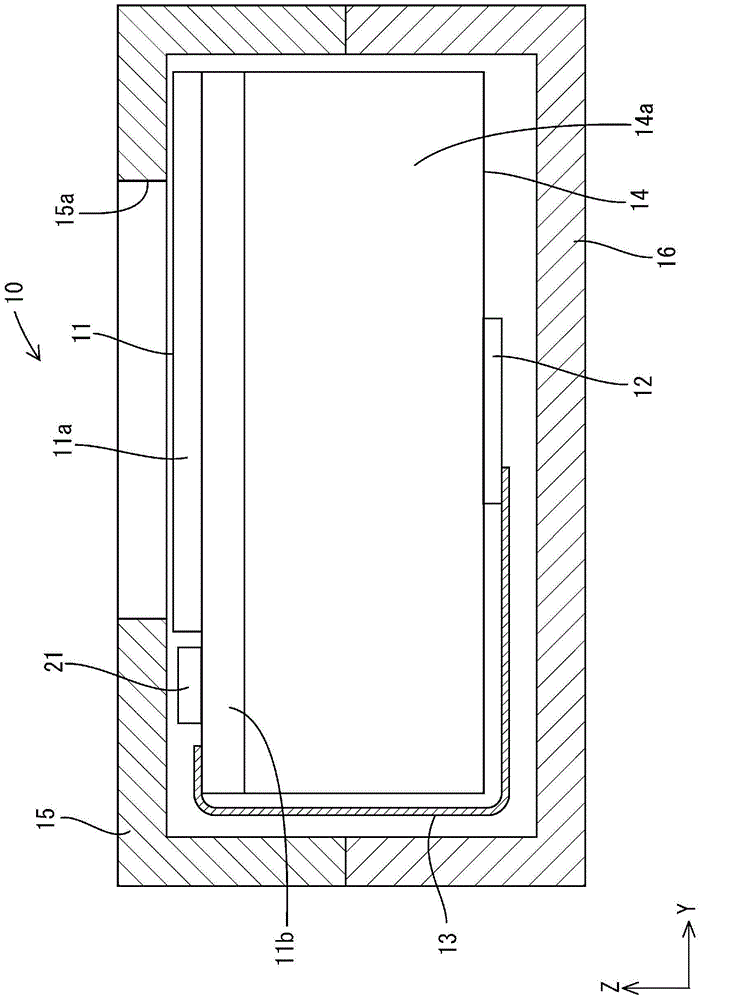

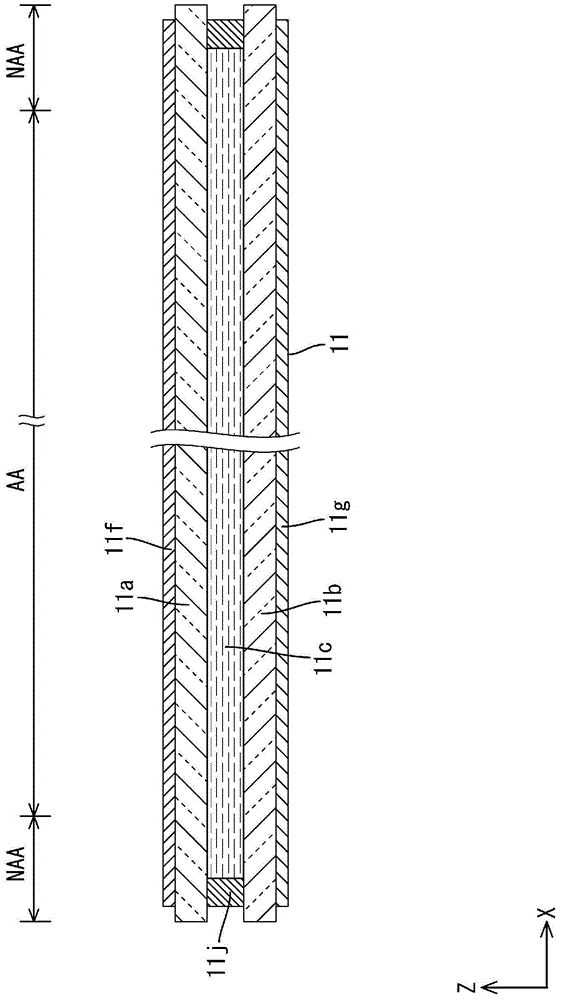

[0047] according to Figure 1 to Figure 14 Embodiment 1 of the present invention will be described. In this embodiment, a liquid crystal display device 10 is illustrated. In addition, X-axis, Y-axis, and Z-axis are shown in a part of each drawing, and it draws so that each axis direction may become the direction shown in each drawing. In addition, regarding the up-down direction, to Figure 2 to Figure 4 etc., and the upper side of the figure is the front side, and the lower side of the figure is the back side.

[0048] Such as figure 1 and figure 2 As shown, the liquid crystal display device 10 includes: a liquid crystal panel (display device, display panel) 1, which has a display portion AA capable of displaying images and disposed on the central side, and a non-display portion disposed on the outer peripheral side so as to surround the display portion AA. NAA; a driver (panel driver) 21 for driving the liquid crystal panel 11; a control circuit board (external signal ...

Embodiment approach 2

[0100] according to Figure 15 or Figure 16 Embodiment 2 of the present invention will be described. In this Embodiment 2, the structure which arrange|positions the common electrode part 122 on the side of the CF substrate 111a is shown. Note that redundant descriptions of the same configurations, actions, and effects as those of the first embodiment described above will be omitted.

[0101] Such as Figure 15 As shown, the common electrode portion 122 of the liquid crystal panel 111 in this embodiment is not arranged on the side of the array substrate 111b having the TFT 117 for the display unit, but on the side of the CF substrate 111a, and the operation mode is VA (Vertical Alignment: vertical alignment) model. The common electrode portion 122 is arranged to be interposed between the alignment film 111d, the color filter 111h, and the light-shielding layer 111i, and is a solid pattern covering almost the entire surface of the CF substrate 111a. On the array substrate ...

Embodiment approach 3

[0103] according to Figure 17 to Figure 19 Embodiment 3 of the present invention will be described. In this Embodiment 3, the structure which arrange|positioned the plane of each gate electrode part 217a, 229a of each TFT217,229 is shown. Note that redundant descriptions of the same configurations, actions, and effects as those of the first embodiment described above will be omitted.

[0104] Such as Figure 17 and Figure 18 As shown, the first gate electrode portion 217 a constituting the TFT 217 for a display portion is formed integrally without branching from the gate wiring 219 . That is, the TFT 217 for a display portion is disposed so as to be placed entirely on the gate wiring 219 . Therefore, the first channel portion 217d constituting the TFT 217 for a display portion is arranged to overlap with the first gate electrode portion 217a (gate wiring 219 ) over the entire area in plan view. same, Figure 17 and Figure 19 As shown, the second gate electrode portio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com