Deeply-loosening and furrowing shovel for garden fertilizing

A technology for deep loosening shovels and orchards, applied in the directions of excavation/covering of trenches, applications, planting methods, etc., which can solve the problems of small space, large cross-section, and inability to form soil voids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the invention.

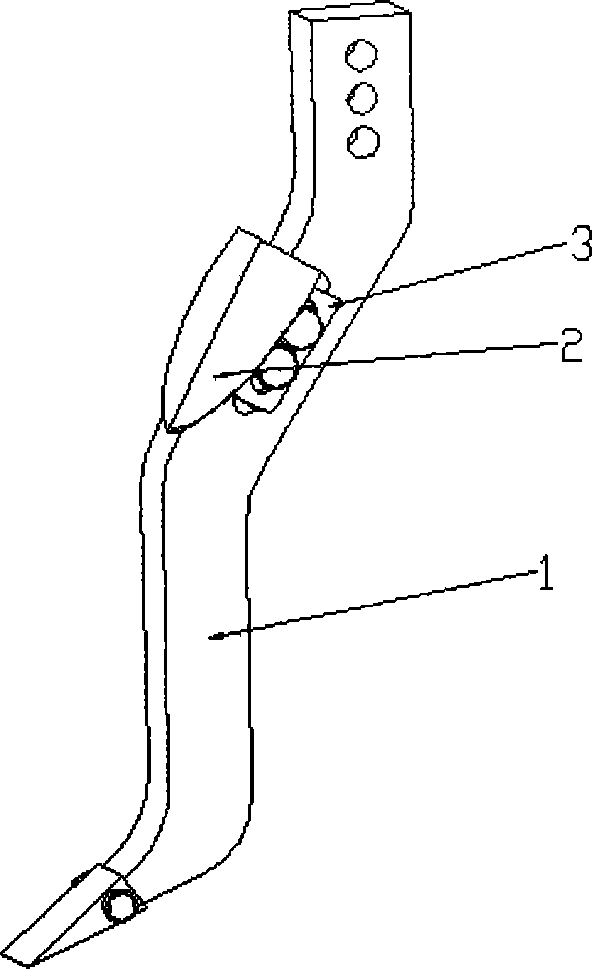

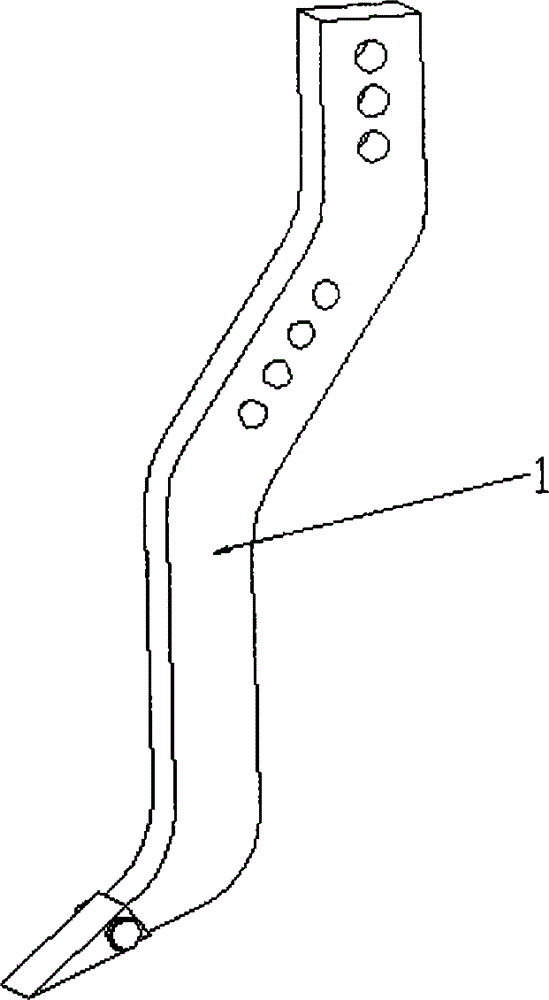

[0015] figure 1 Shown is the structure of the deep loosening ditch shovel dedicated to orchard fertilization provided by the embodiment of the present invention. For ease of illustration, only the parts relevant to the present invention are shown.

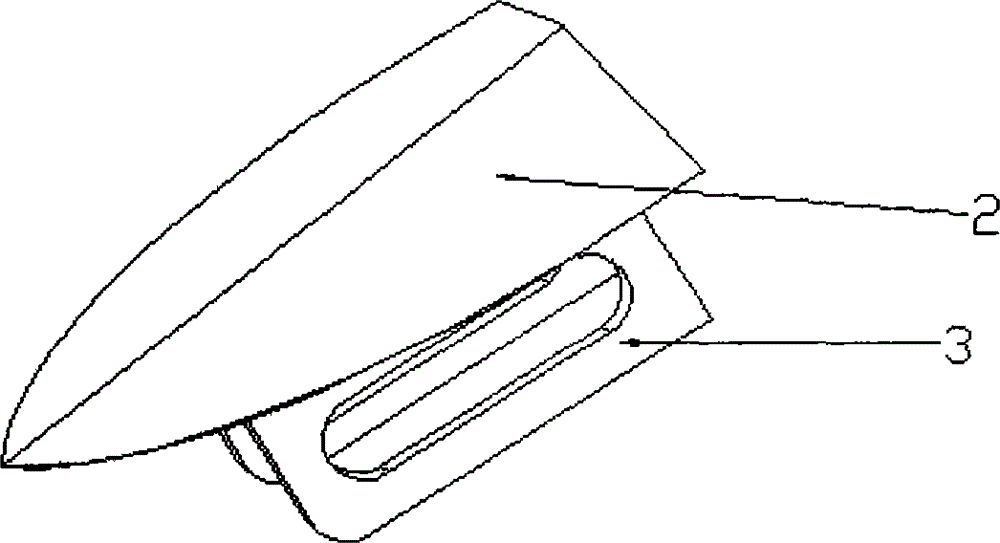

[0016] The special deep loosening ditch shovel for fertilization in the orchard includes: subsoiling shovel 1, ditching share 2, rib plate 3;

[0017] Two rib plates 3 are welded on the lower surface of the ditch share 2 symmetrically along the longitudinal direction of the ditch share 2, and the gap between the two rib plates 3 is equal to the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com