Construction tools for making fence topping

A construction tool and wall technology, applied in the connection of formwork/formwork/work frame, construction material processing, formwork/formwork/work frame, etc., can solve wall peeling damage, time-consuming and labor-consuming, turnover Poor performance and other problems, to achieve the effect of simple construction, beautiful appearance and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

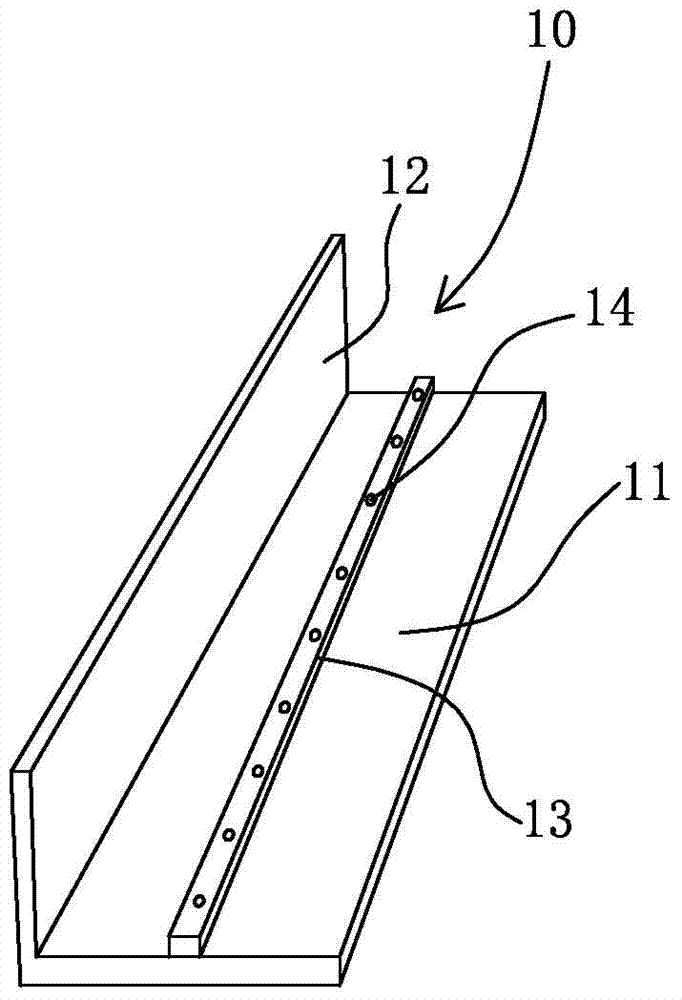

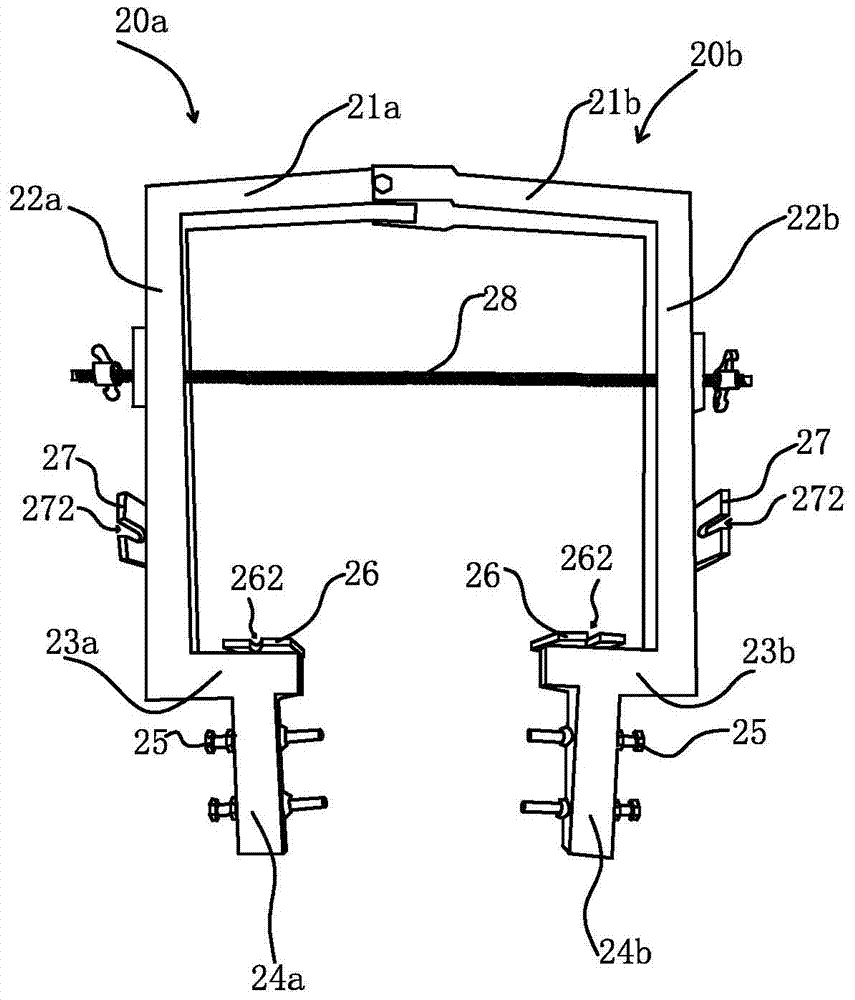

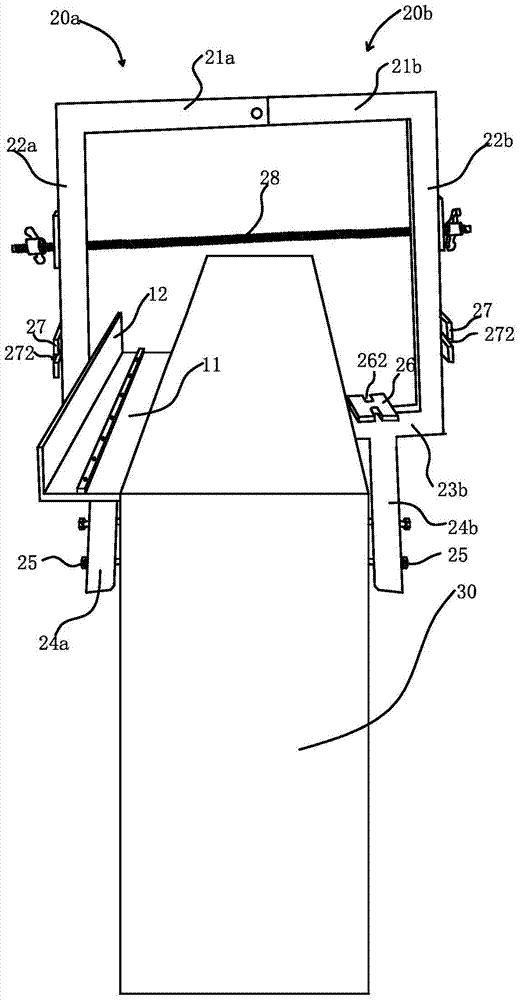

[0036] like figure 1 As shown, the construction tool of the present invention includes an angle iron formwork 10 for pouring enclosure wall topping. The angle iron formwork 10 includes a first plate body 11 perpendicular to the outer wall of the wall body 30 and arranged in a horizontal direction, and away from the outer wall of the body of wall 30 and located at the first plate body 11. The second plate body 12 above the plate body 11 is located inside the angle steel mold 10, and the plate surface of the first plate body 11 is provided with a convex strip 13 for forming a drip groove at the bottom surface of the enclosure wall. Using the angle steel mold 10 of the present invention to construct the drip tank can make the drip tank and the wall topping integrally formed, the service time is longer, it is not easy to be damaged, the construction of the drip tank is simple, and at the same time, the external wall topping is guaranteed to be more beautiful. The tool has good tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com