An upper chassis with insect resistance suitable for automatic insect traps

An insect trap and insect repellent technology, applied in the field of insect trap, can solve the problems of crop pesticide residues, high energy consumption, noise generation, etc., and achieve the effects of enhancing heat dissipation performance, enhancing heat dissipation effect, and enhancing air convection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

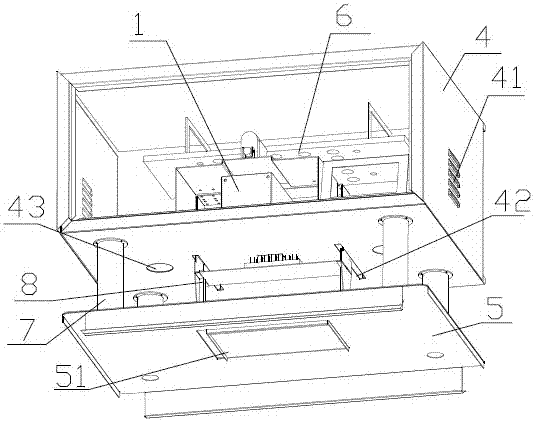

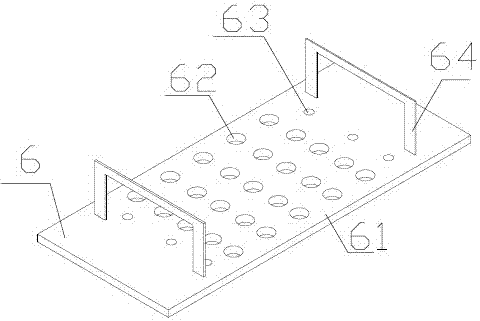

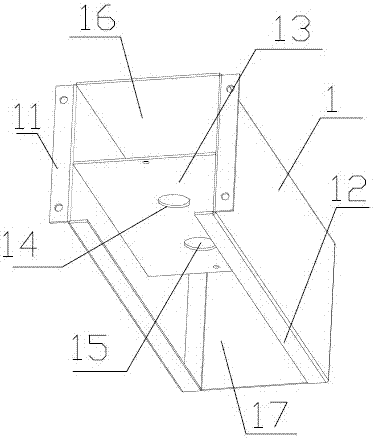

[0041] Example 1, such as figure 1 — Image 6 Shown: an upper chassis suitable for automatic insect traps with insect resistance, comprising a chassis body 4 and a light frame 8 connected to the bottom of the chassis body 4 and used for trapping lamps, and at least two side panels of the chassis body 4 contain row Thermal window 41, insect-proof gauze is installed on the heat-discharging window 41, and the bottom surface of cabinet body 4 is provided with the camera that stays for shooting and is positioned at the slide groove 42 that the light frame 8 slides for the both sides of the camera stay, and slide groove 42 is provided with Moth-proof gauze is arranged, and lamp holder 8 is provided with the hairbrush 83 that is used to block up the camera opening on the one side facing cabinet body 4. The chassis body contains the camera, various electronic components that control the operation of the camera and store the camera shooting data, which will generate a certain amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com