Rolling method of noodle sheet in fresh noodle production

A technology for fresh noodles and noodle slices, which is applied in the direction of dough extruders, etc. It can solve the problems of high environmental requirements in the workshop, noodles are easy to break, and affects the cooking time of the final product, so as to achieve scientific and reasonable methods and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

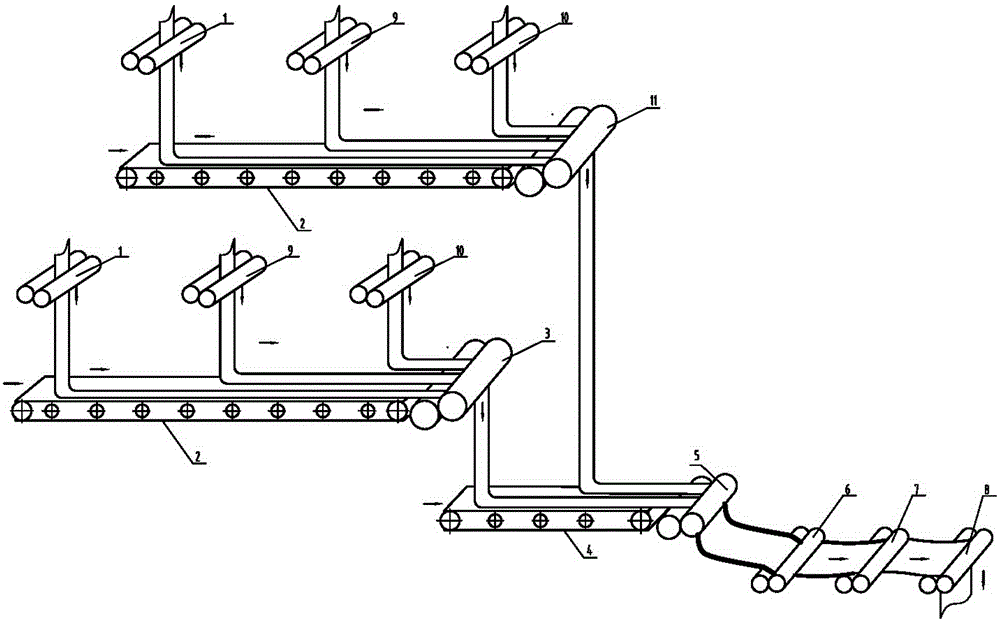

[0020] Depend on figure 1 It can be seen that a method for rolling dough sheets in the production of fresh noodles, which includes initial pressure shaping, compound calendering and continuous calendering of dough sheets. In initial pressure shaping, the continuous dough sheets pressed by 3 to 6 sets of shaping rollers On the moving conveyor belt of the shaping section, there are 3 to 6 layers of continuous dough, that is, the continuous dough sheet pressed by the first set of shaping rollers 1 falls on the moving conveyor belt 2 of the shaping section, and the second set of shaping rollers 9 presses it. The continuous dough that comes out falls on the continuous dough that the first group of shaping rollers 1 suppresses, and the continuous dough that the third group of shaping rollers 10 suppresses falls on the continuous dough that the second group of shaping rollers 9 suppresses. By analogy, the thickness of the continuous dough sheet pressed by each shaping roller group is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com