Garbage station waste gas processing and deodorizing system

A waste gas treatment and garbage station technology, which is applied in the direction of shielding with air flow, heating methods, lighting and heating equipment, etc., can solve the problems of low timeliness of volatile substances, high investment and operation costs, and large floor area, etc., to achieve investment Low operating cost, significant deodorizing effect, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

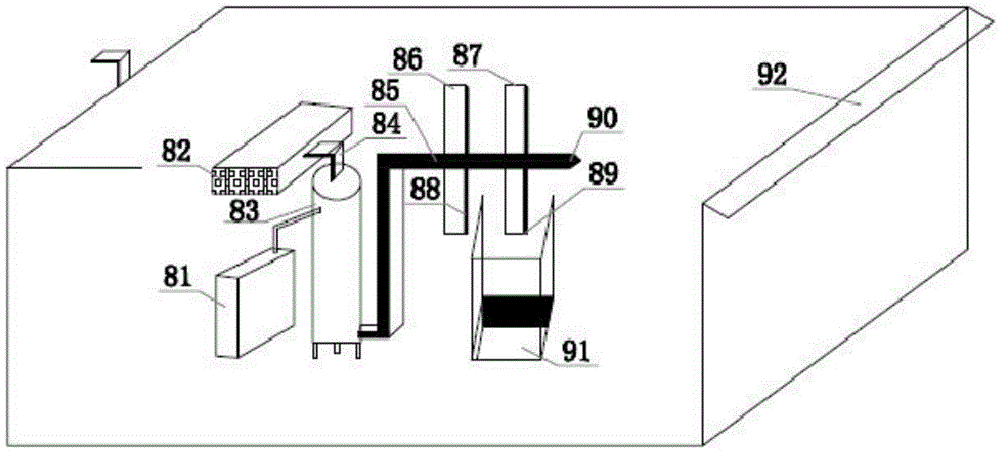

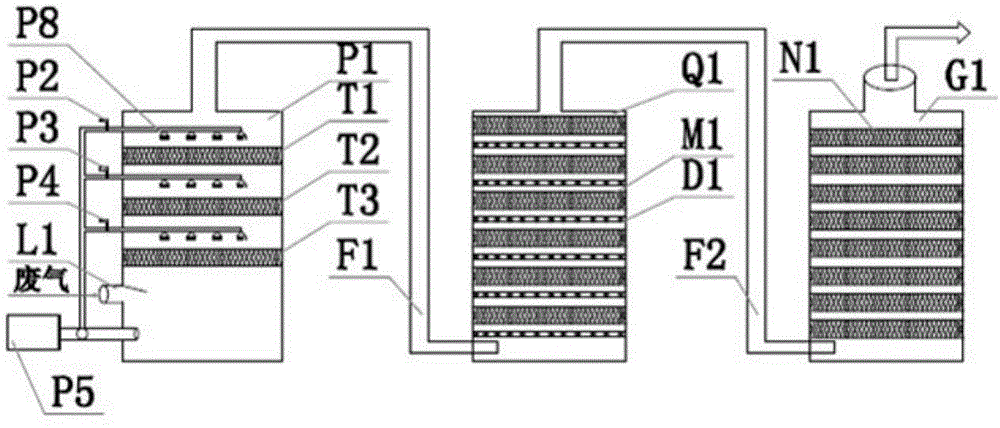

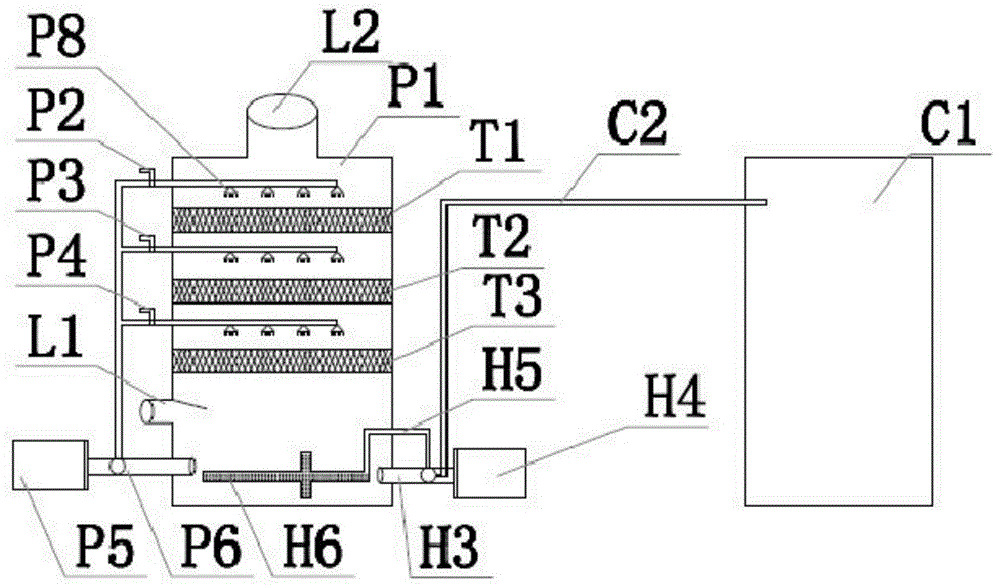

[0021] like Figure 1 to Figure 4 As shown, the waste gas treatment and deodorization system of the garbage station of the present invention includes a ventilation collection device, a waste gas treatment device and a control device. The ventilation collection device includes a suction duct 85 and an exhaust duct 84, and the suction duct 85 is provided with a first suction port 87, a second suction port 90, a third suction port 89, a fourth suction port 88 and a first suction port 88. Five air suction ports 86, the air suction duct 85 is placed above the garbage compression equipment 91 in the garbage station, so that the first air suction port 87, the second air suction port 90, the third air suction port 89, and the fourth air suction port 88 And the fifth air suction port 86 is located above the garbage compression equipment 91, so that when the garbage compression equipment 91 compresses the garbage, the smell in the garbage passes through the first air suction port 87, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com