Automatic powder mixing device

A mixing device and automatic technology, applied in mixers, mixers with rotating containers, dissolving and other directions, can solve the problems of low work efficiency, high cost, worker health impact, etc., and achieve high work efficiency, reduced labor intensity, Physical health is not affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

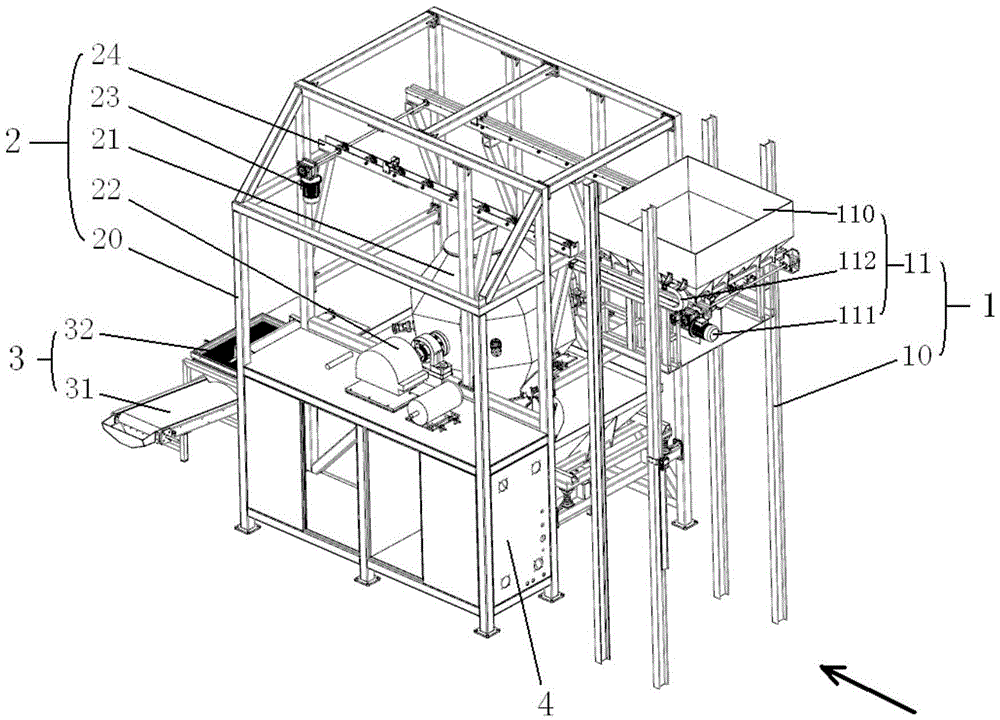

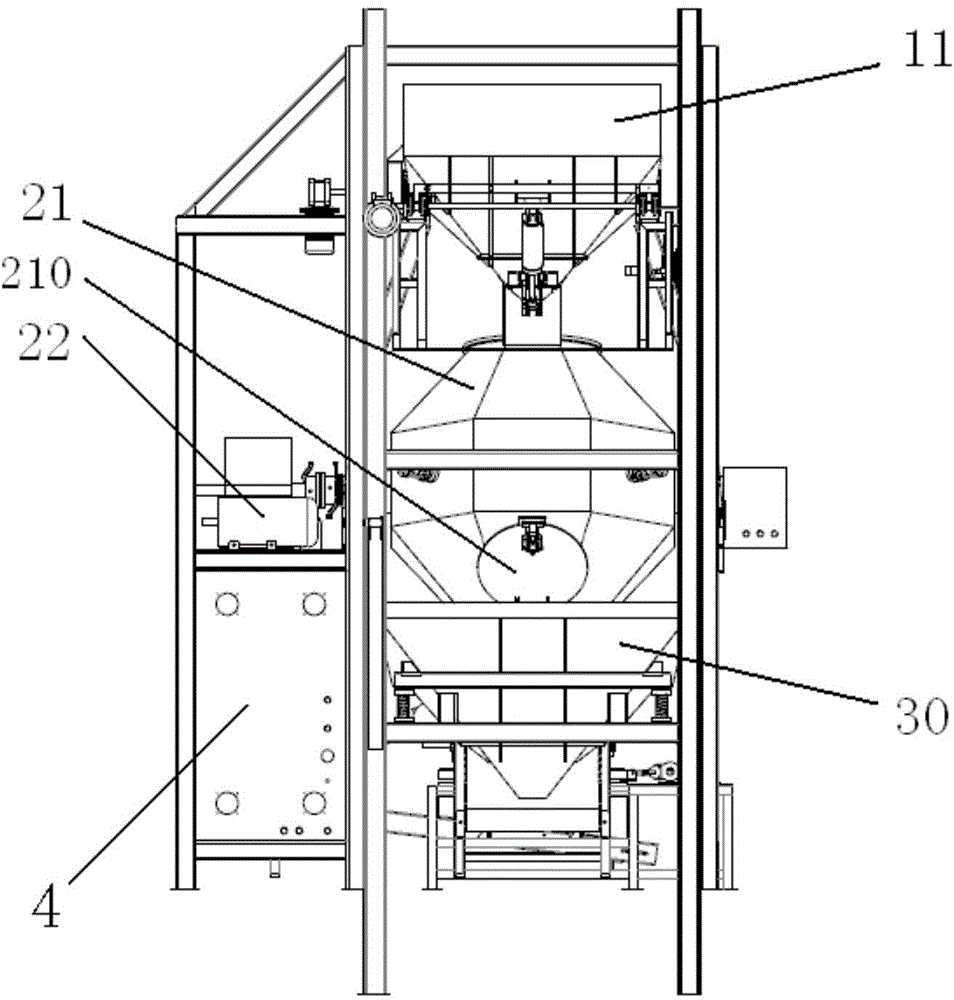

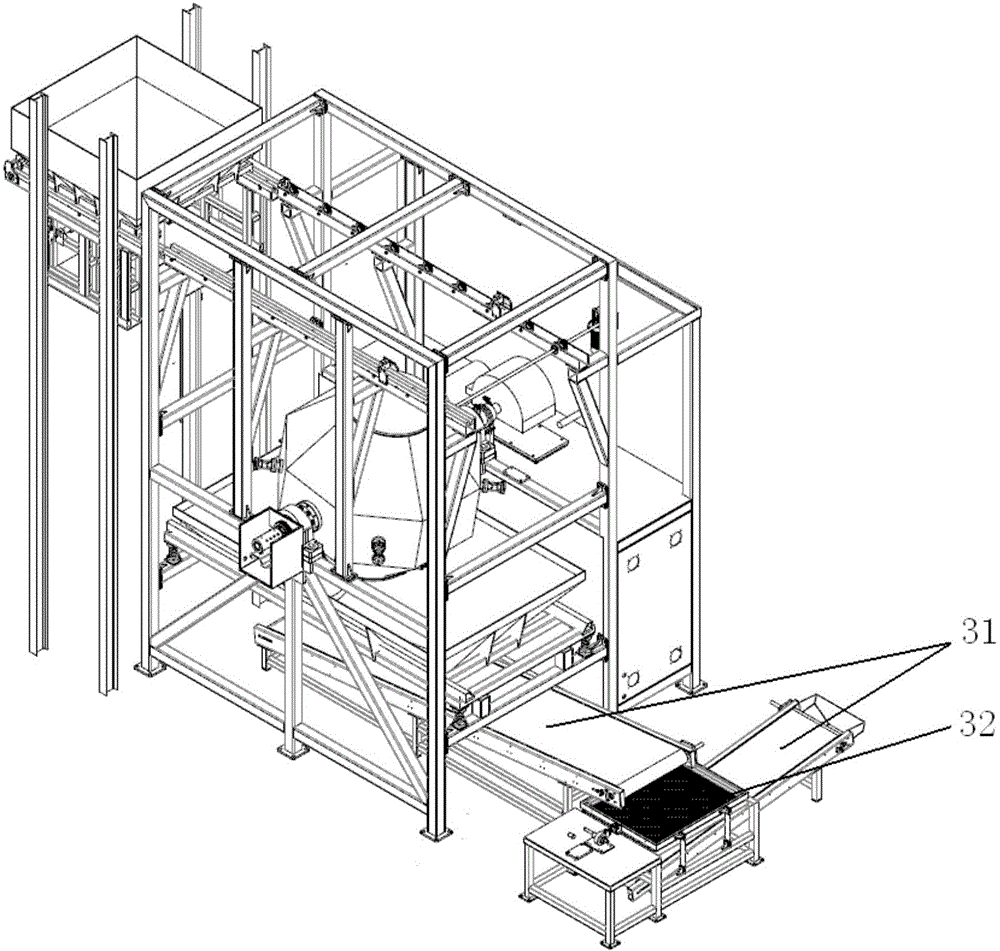

[0016] An example of the present invention is figure 1 , 2 and 3. An automatic powder mixing device, the mixing device includes a hydraulic platform lifting feeding part 1 controlled by a PLC automatic control part 4, a hopper translation and mixing part 2, and a feeding part 3; the platform lifting The feeding part 1 includes a platform lifting frame 10 and a platform 11 located in the platform lifting frame 10; a hopper 110 with a lower opening is placed on the platform 11, and a motor-driven hopper translation mechanism, which includes a translation motor 111 and The translation guide rail 112; the opening of the hopper 110 is provided with a baffle plate for an electric drive switch; the translation and mixing part of the hopper includes a frame 20, which is located at the top of the frame 20 and the lifting and loading part 1 of the platform. The hopper relay translation mechanism docked by the hopper translation mechanism, the rotating mixing bucket 21 located in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com