Raw material mixing and grinding device for ceramic dry granulation

A technology of dry granulation and crushing device, which is applied in the direction of granulation in static tank/tank, grain processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

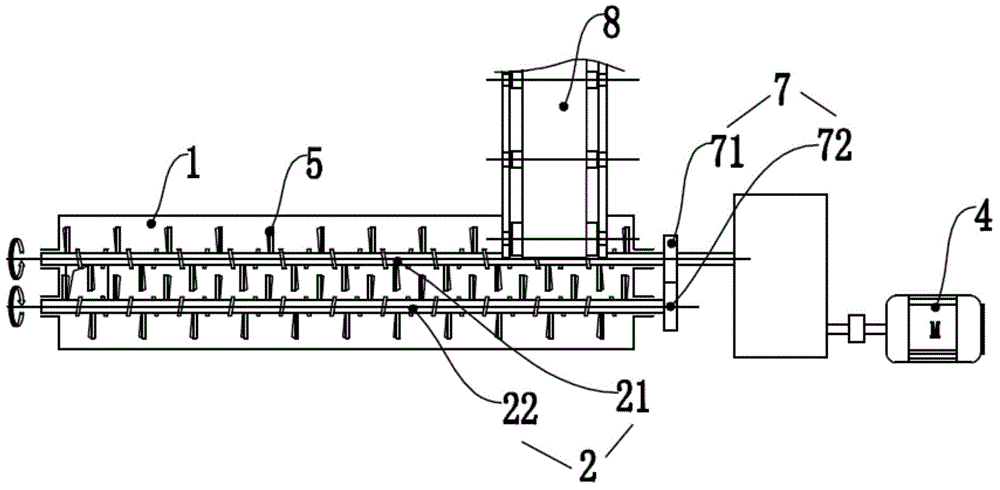

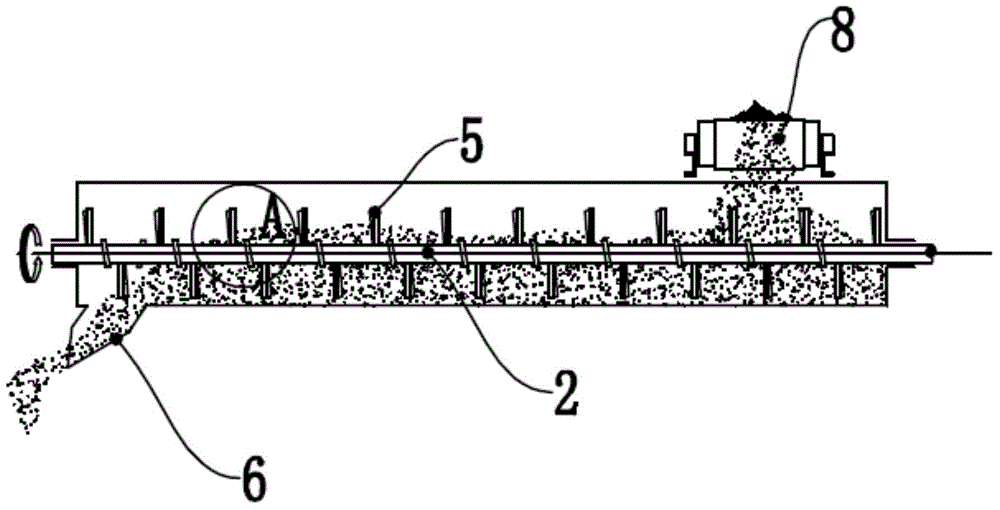

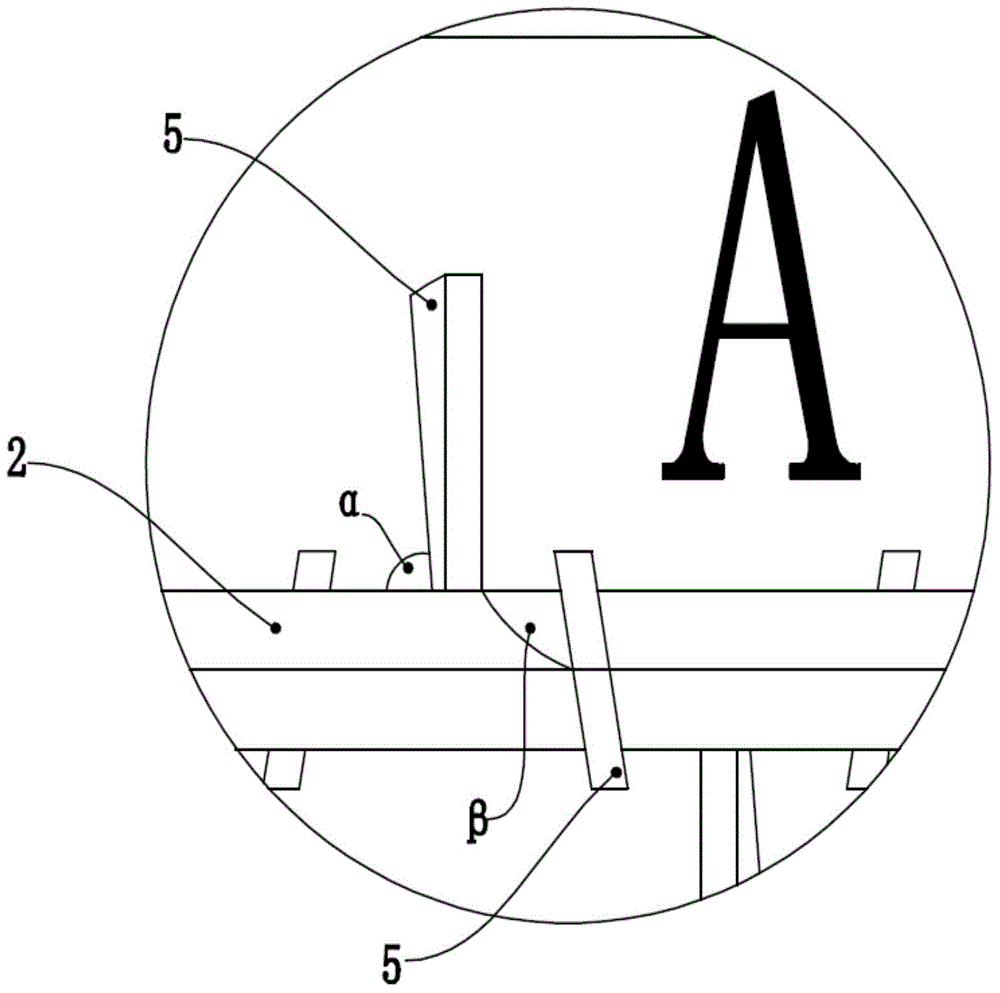

[0023] Such as figure 1 and figure 2 As shown, a raw material mixing and crushing device for ceramic dry granulation includes a mixing box 1, a first stirring shaft 21, a second stirring shaft 22 and a driving device 4; the first stirring shaft 21 and the second stirring shaft Shafts 22 pass through the mixing box mixing box 1, and blades 5 are arranged at intervals on the first stirring shaft 21 and the second stirring shaft 22 in the mixing box 1; the output end of the driving device 4 is connected to the The first stirring shaft 21 is connected, and the second stirring shaft 22 is connected with the first stirring shaft 21 through a transmission device; the mixing box 1 is provided with a discharge port 6 .

[0024] The process of dry granulation is: mud mixing (viscous raw materials and barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com