Alkaline phenolic resin old sand and regeneration method thereof

A technology for regeneration of phenolic resin and old sand, which is used in casting and molding equipment, molds, cores, etc., can solve the problems of chemical regeneration, which is difficult to popularize, cannot remove resin film, and harms human health, so as to improve regeneration. Effective, less harmful, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

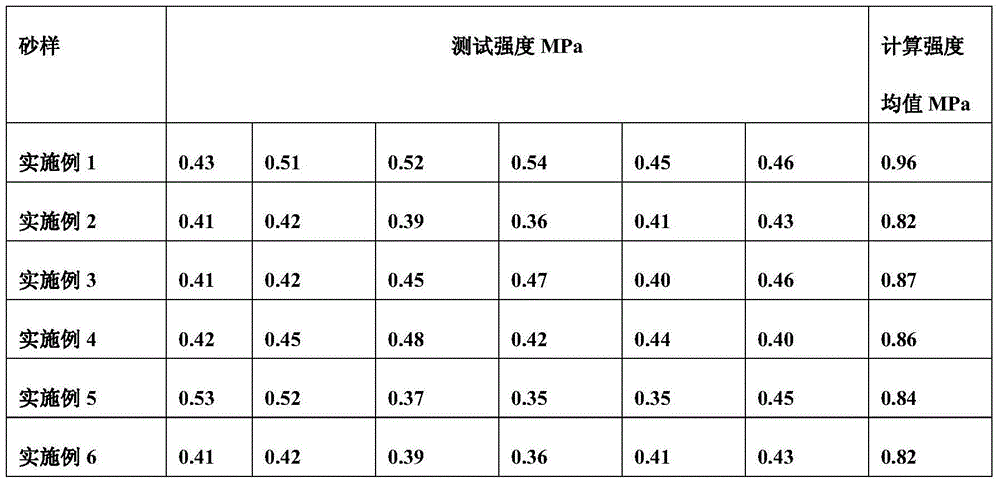

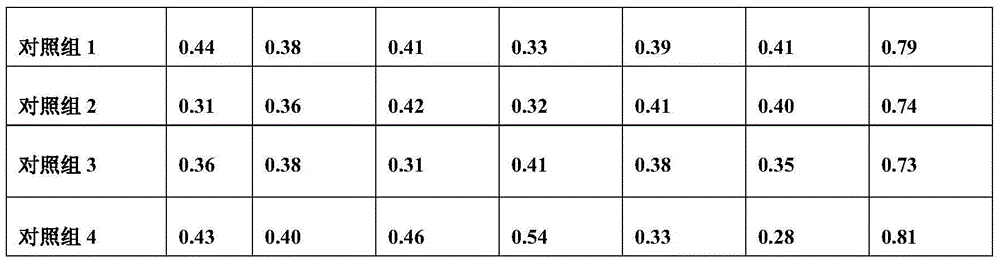

Examples

Embodiment 1

[0023] The present embodiment relates to the regeneration of the old sand of alkaline phenolic resin, and the regeneration method comprises the steps:

[0024] (1) In the old alkaline phenolic resin sand (no-hardening sand obtained with liquid alkaline phenolic resin as a binder and diethylene glycol acetate curing agent), mix 1% powder calcium carbonate with a mass of it, and mix evenly Afterwards, heat to 750°C for thermal regeneration for 40 minutes;

[0025] (2) Cool the old sand regenerated by the thermal method to normal temperature, then pass through a 16-mesh sieve to remove large particles of slag, pass through a 140-mesh sieve to remove fine sand particles, and finally winnow the dust to obtain alkaline phenolic resin regenerated sand.

Embodiment 2

[0027] Compared with Example 1, the only difference is that the powder described in this example is magnesium carbonate, the heating temperature is 650° C., and the heat treatment time is 50 minutes.

Embodiment 3

[0029] Compared with Example 1, the difference is only that the powder described in this example is barium carbonate, the heating temperature is 800° C., and the heat treatment time is 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com