Ladle automatic drainage device

A ladle and automatic technology, applied in the direction of casting melt container, metal processing equipment, casting equipment, etc., can solve the problems of not being able to form a complete arc-shaped sand dune, the change of the performance of the drainage sand, and the super-long refining waiting time, etc., to achieve Improve the automatic pouring rate, large capacity, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

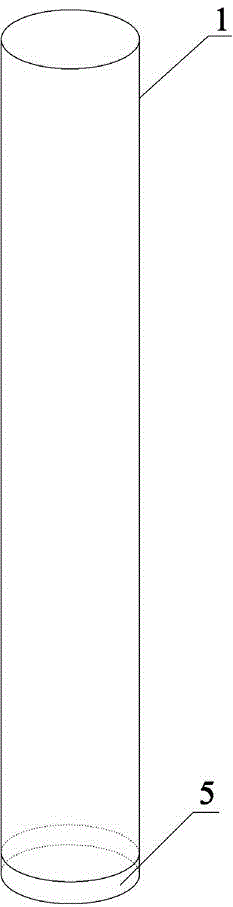

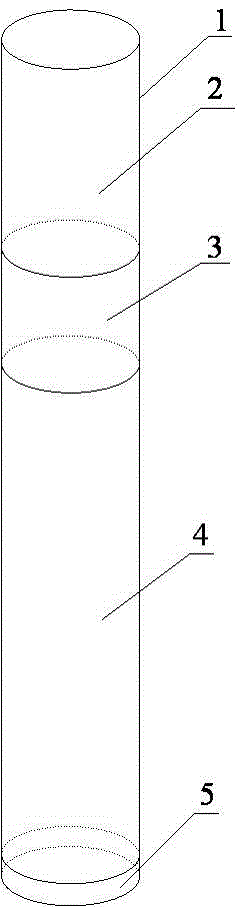

[0034] The ladle automatic drainage device of the present invention includes a cylinder body 1 and drainage materials, the drainage material is a single-layer structure, the cylinder body 1 is made of prefabricated thin-walled steel, and the top of the cylinder body 1 is sealed with prefabricated thin-walled steel, and the The bottom of cylinder body 1 adopts hard low-temperature melting plastic sealing 5.

[0035] Specifically, the drainage material is made of 50.1 parts by weight of chrome sand, 48.5 parts by weight of silica sand, and 1.4 parts by weight of carbon black and / or graphite. Wherein, the particle size of the chromium ore is 20-80 mesh; the particle size of the silica sand is 0.2-2 mm. The preparation method of the above-mentioned drainage material is an existing conventional technology.

[0036] In addition, the size design of the cylinder 1 meets the following requirements: the height of the cylinder 1 is 100-300 mm higher than the bottom of the ladle, and the...

Embodiment 2

[0040] The device structure of this embodiment is the same as that of Embodiment 1, except that the drainage material is made of 94.5 parts by weight of chrome sand, 5.2 parts by weight of silica sand, and 0.3 parts by weight of carbon black and / or graphite. The particle size of the chrome ore is 20-80 mesh. The particle size of the silica sand is 0.2-2 mm.

[0041] The preparation methods of the drainage materials are existing conventional techniques. Its method of use and size requirements are the same as in Embodiment 1, and will not be repeated here.

[0042] The ladle automatic drainage device of this embodiment is used in a B steel factory. The number of counted furnaces is 1012 furnaces; the number of pouring furnaces is 1010 furnaces, the automatic pouring rate is 99.8%, and the waiting time for steel is 2.5 to 3 hours.

Embodiment 3

[0044]The device structure of this embodiment is the same as that of Embodiment 1, except that the drainage material is made of 70.8 parts by weight of chrome sand, 26.2 parts by weight of silica sand, and 3.0 parts by weight of carbon black and / or graphite. The particle size of the chrome ore is 20-80 mesh. The particle size of the silica sand is 0.2-2 mm.

[0045] Wherein, the preparation method of the drainage material follows the existing conventional technology. Its method of use and size requirements are the same as in Embodiment 1, and will not be repeated here.

[0046] The ladle automatic drainage device of this embodiment is used in a steel factory A, and the number of counted furnaces is 1007 furnaces; the number of pouring furnaces is 1007 furnaces, the automatic pouring rate is 100%, and the waiting time for steel exceeds 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com