Novel environment-friendly dust suppression stuffing sand and preparation method thereof

A technology for drainage sand and environmental protection, applied in the field of iron and steel smelting and casting, can solve the problems of large black smoke and dust, easy environmental pollution, adverse health effects of operators, etc., and achieves the effects of low price, simple preparation, and excellent resistance to molten steel penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In a preferred embodiment, the novel environment-friendly dust suppression and drainage sand of the present invention comprises the following components by weight: 1 part of 100-60 mesh quartz sand; 12 parts of 60-32 mesh quartz sand; 32-18 mesh quartz sand 75 parts of sand; 4 parts of 18-10 mesh quartz sand; 2 parts of carbon black powder; 3 parts of 60 mesh low-density polyethylene particles.

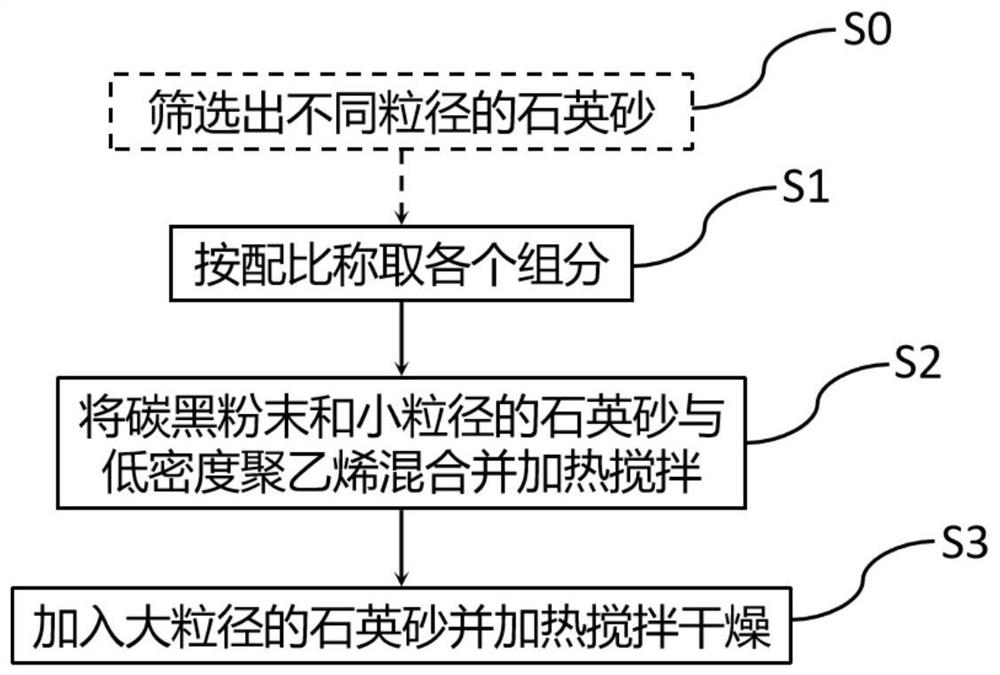

[0045] The preparation method of the novel environment-friendly dust suppression drainage sand of embodiment 1 comprises the following steps:

[0046] Step S0: Use 10 mesh, 18 mesh, 32 mesh, 60 mesh and 100 mesh screens to screen the particle size of the quartz sand to obtain 18~10 mesh, 32~18 mesh, 60~32 mesh, 100~60 mesh And quartz sand with different particle sizes below 100 mesh;

[0047] Step S1: By weight, weigh 1 part of 100-60 mesh quartz sand, 12 parts of 60-32 mesh quartz sand, 75 parts of 32-18 mesh quartz sand, 4 parts of 18-10 mesh quartz sand, and 2 parts of carb...

Embodiment 2-16

[0051] The preparation method of embodiment 2-16 is basically the same as embodiment 1, and its difference is, the particle size of the drainage sand component of embodiment 2-16 and low-density polyethylene particle is shown in the following table:

[0052]

Embodiment 17

[0054] The new environment-friendly dust suppression and drainage sand of embodiment 17 comprises the following components by weight: 1 part of 100-60 mesh quartz sand; 12 parts of 60-32 mesh quartz sand; 75 parts of 32-18 mesh quartz sand; 18-10 4 parts of mesh quartz sand; 2 parts of carbon black powder; 3 parts of low-density polyethylene particles.

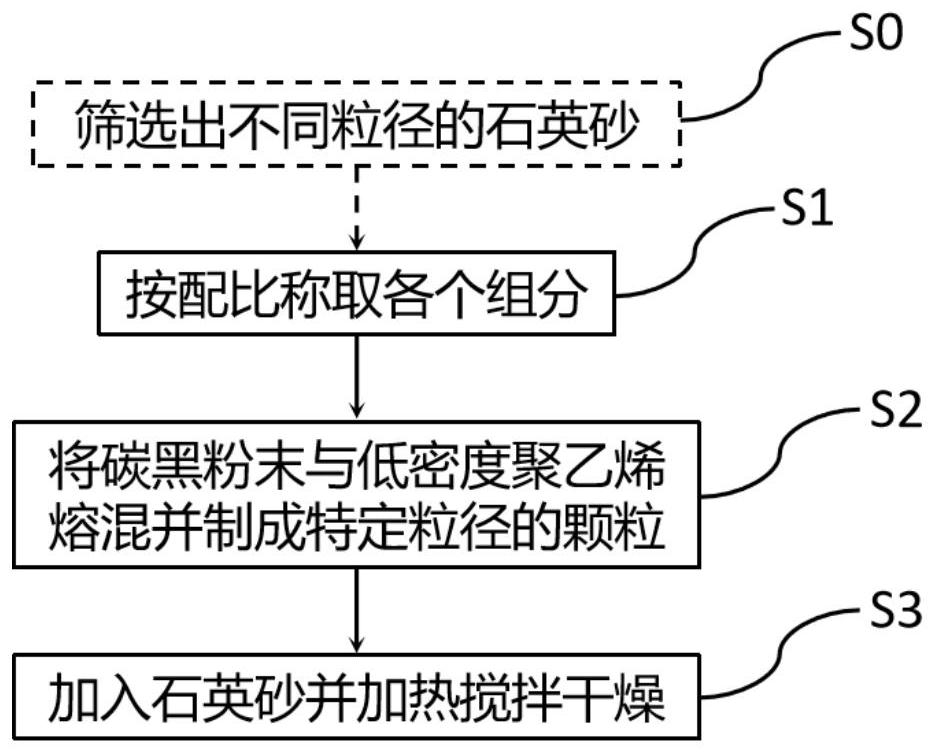

[0055] The preparation method of the novel environment-friendly dust suppression drainage sand of embodiment 17 comprises the following steps:

[0056] Step S1: By weight, weigh 1 part of 100-60 mesh quartz sand, 12 parts of 60-32 mesh quartz sand, 75 parts of 32-18 mesh quartz sand, 4 parts of 18-10 mesh quartz sand, and 2 parts of carbon black powder 3 parts, 3 parts of low-density polyethylene;

[0057] Step S2: put the carbon black powder and the low-density polyethylene particles into a heatable mixer, and stir well at 170° C.; then put the mixture into a granulator to make 60-mesh mixture particles;

[0058] Step S3: A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com