Three-dimensional vertical type carving machine

An engraving machine and vertical technology, which is applied in the field of engraving machines, can solve the problems of limited engraving workpieces and easy occurrence of defective products, and achieve the effect of stable center of gravity, guaranteeing processing, and preventing offset.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

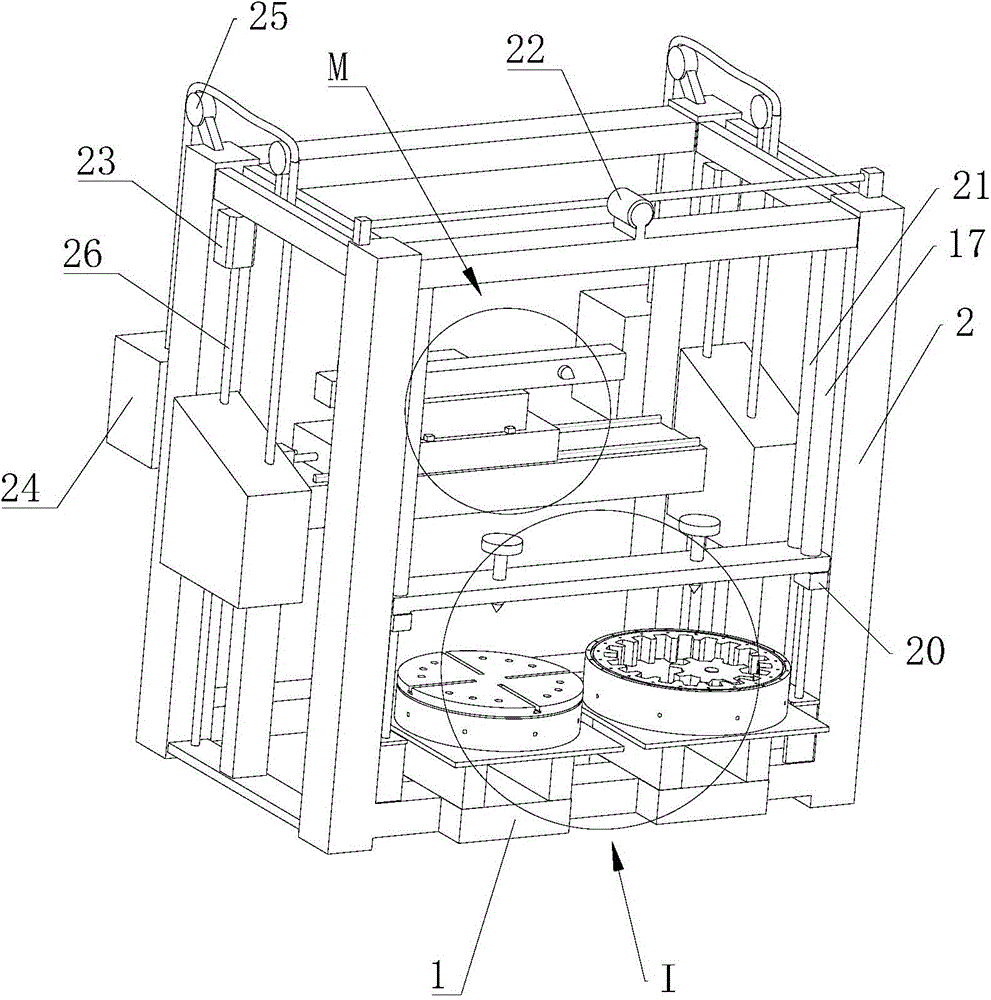

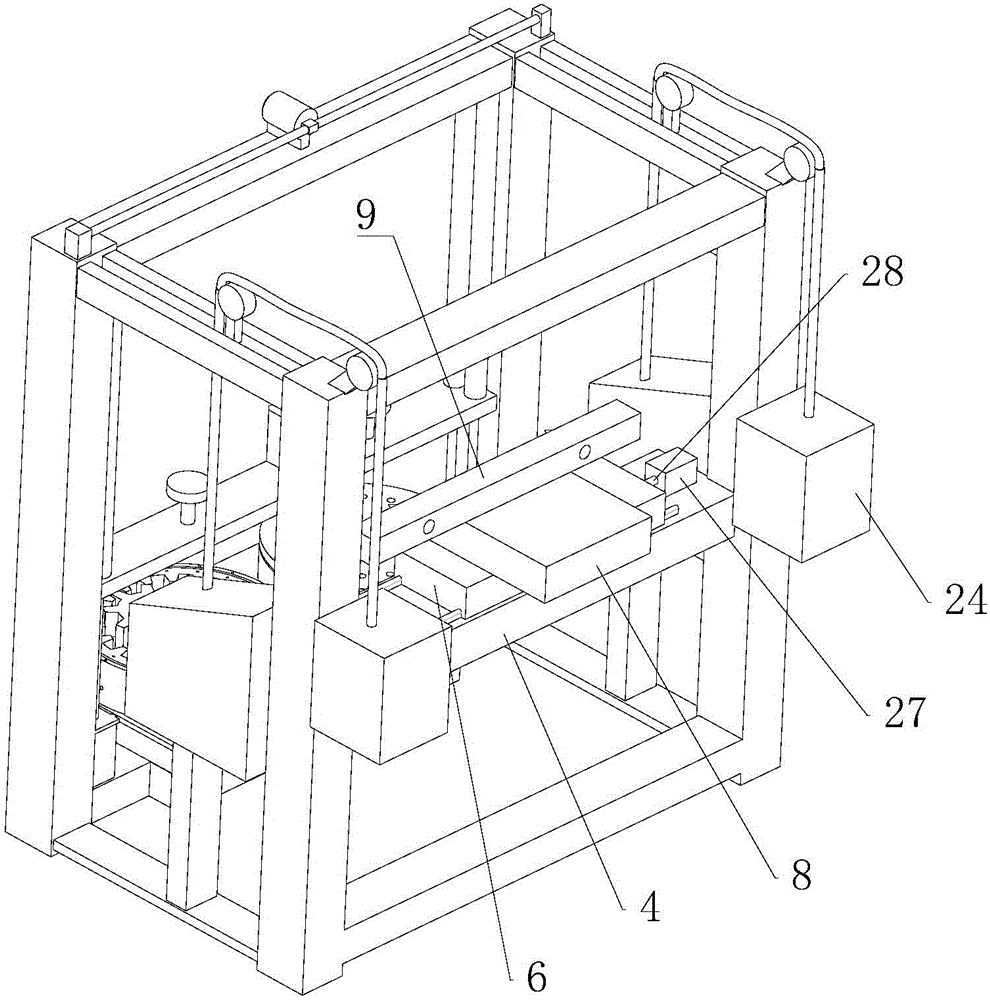

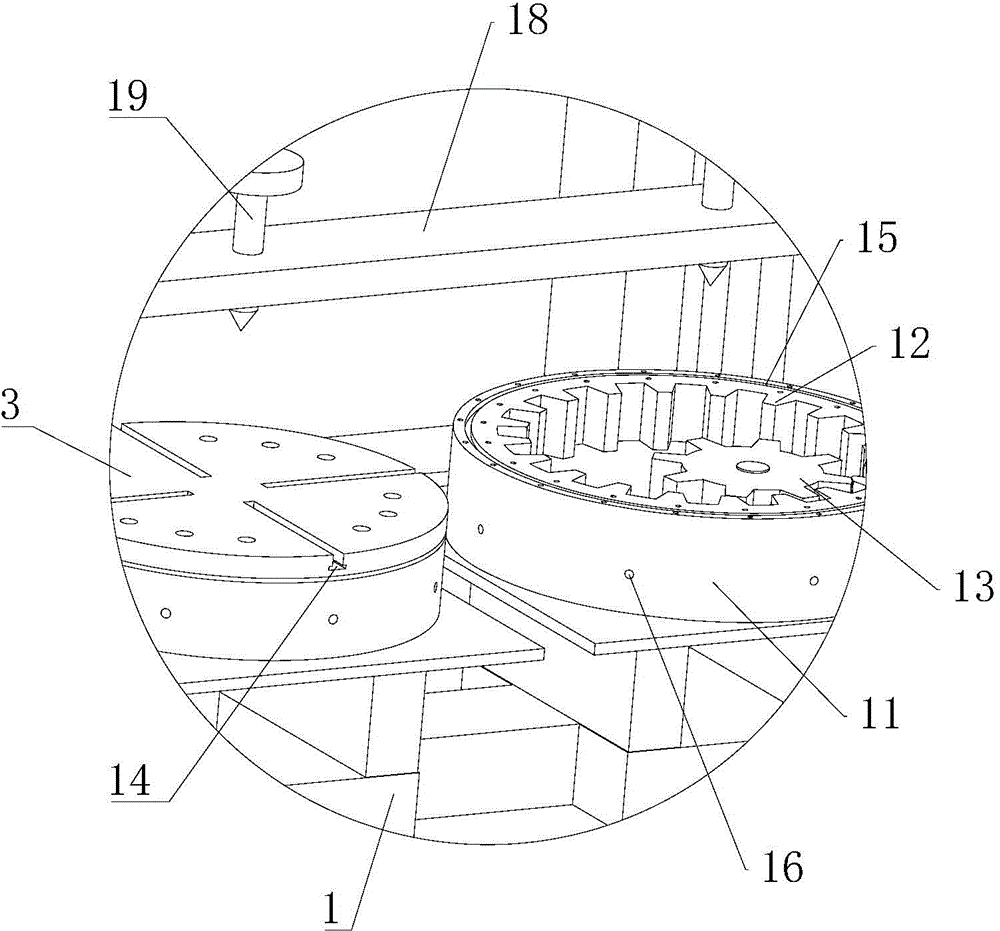

[0042] like figure 1 and figure 2 As shown, it is an embodiment of the three-dimensional vertical engraving machine of the present invention. The three-dimensional vertical engraving machine first includes a base 1 and a gantry frame 2 fixed therewith, and a rotatable horizontal workbench 3 is set on the base 1. And the number of horizontal workbench 3 is at least one (shown two in this embodiment), its effect is exactly to place the workpiece to be processed, and positioning mechanism, engraving mechanism are respectively installed on portal frame 2, wherein, The positioning mechanism locates and fixes the workpiece on the horizontal workbench 3, while the engraving mechanism directly engraves the positioned and fixed workpiece. During engraving, the horizontal worktable 3 rotates according to the set speed, and at the same time the engraving mechanism feeds according to the route set in advance, and finally completes the engraving of the workpiece.

[0043] The advantage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com