Method for operating an automatic parking brake

A parking brake and brake caliper technology, applied in the field of controllers, can solve problems such as jamming and automatic parking brake disconnection cannot be guaranteed, and achieve the effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

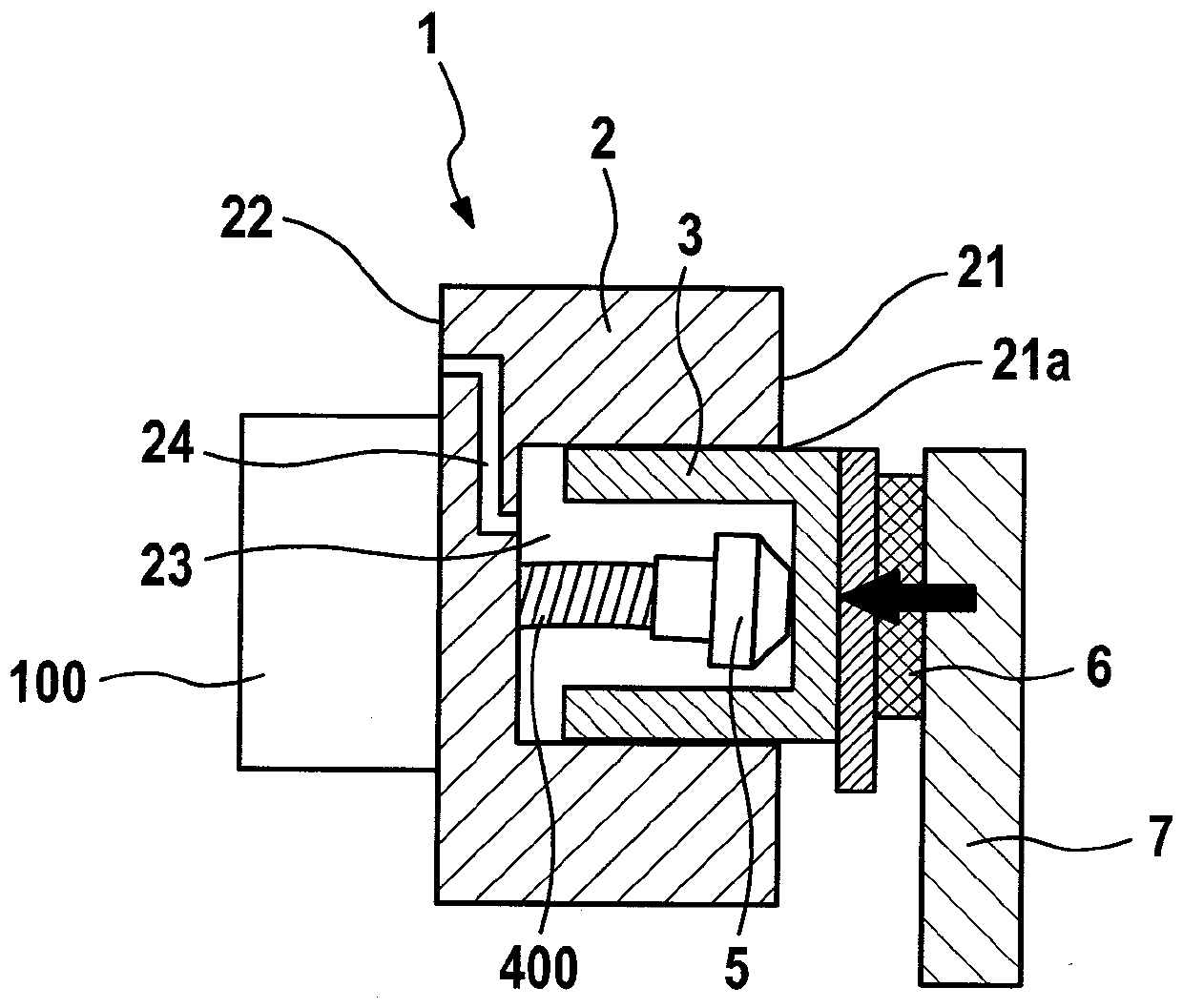

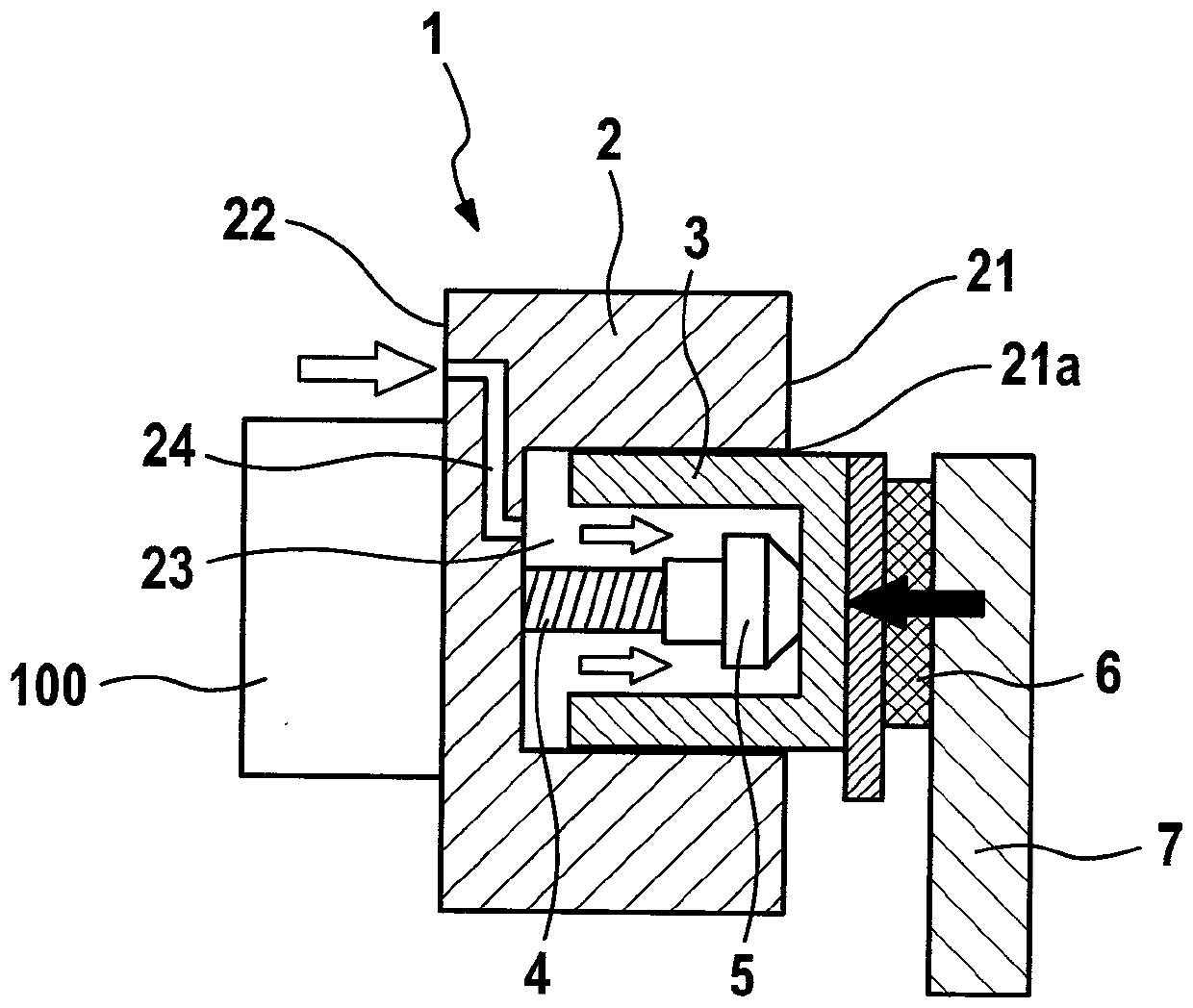

[0021] Refer below figure 2 The first embodiment of the present invention will be described. A braking device 1 for an automatic (automatic) parking brake (parking brake) comprises a brake caliper housing 2 or a brake caliper, a brake piston 3, a spindle 4, in particular a spindle, and A spindle nut 5 . Furthermore, the parking brake has an electric motor-gear unit (MGU) 100 and on the brake piston side at least one brake lining 6 and a brake disc 7 .

[0022] The caliper housing 2 comprises a first end 21 with a first opening 21 a for receiving the brake piston 3 , a second end oriented in the direction of the motor-transmission unit 100 . 22 and an inner chamber 23 for receiving fluid or brake fluid. Furthermore, hydraulic lines 24 for supplying brake fluid into the inner chamber 21 or for draining the brake fluid from the inner chamber 21 are provided in the caliper housing 2 .

[0023] The brake piston 3 is substantially cylindrical and has a blind hole pointing in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com