Online emergency maintenance method and online emergency maintenance system of molten salt storage tank

An emergency maintenance, molten salt technology, applied in the direction of container, packaging, transportation and packaging, can solve the problems of affecting the normal operation of the power station, polluting the insulation layer of the storage tank, the insulation of the foundation, and endangering the safety of the power station, etc., to achieve low cost, reduce Losses, the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

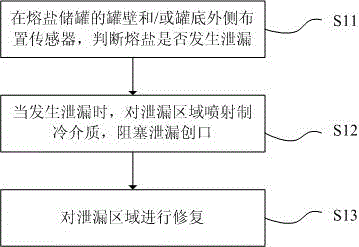

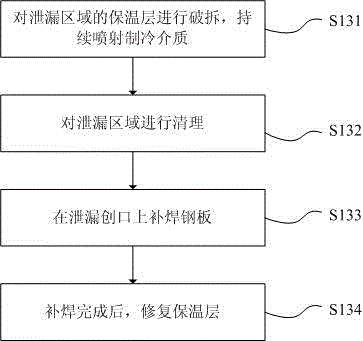

[0043] combine Figure 1-Figure 8 , this embodiment describes in detail the online emergency maintenance method of the molten salt storage tank of the present invention, which includes the following steps:

[0044] S11: arrange sensor 1 outside the tank wall and / or tank bottom of the molten salt storage tank, and sensor 1 detects whether the molten salt leaks;

[0045] S12: When the sensor 1 detects that the molten salt leaks, inject a refrigerant medium to the leakage area where the sensor 1 is located, and block the leakage wound;

[0046] S13: Repair the leakage area.

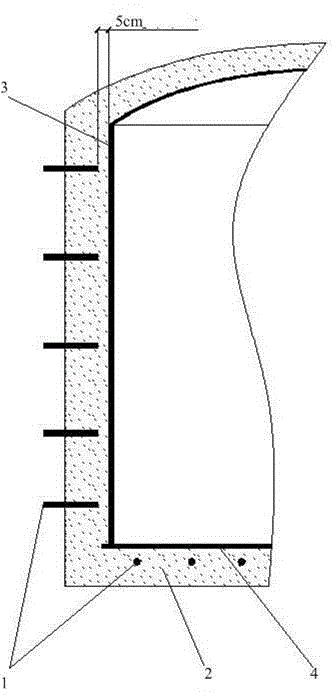

[0047] Wherein, S11 is specifically: dividing the tank wall 3 and / or tank bottom 4 of the molten salt storage tank into grids, and arranging a sensor 1 at the center of each grid, and the sensor 1 is arranged in the insulation layer 2 of the molten salt storage tank , the distance between the sensor 1 and the tank wall 3 and / or tank bottom 4 of the molten salt storage tank is 5cm, there is a large temperat...

Embodiment 2

[0056] This embodiment describes in detail the online emergency maintenance system for molten salt storage tanks of the present invention, which is a system for implementing the above maintenance method, including: sensors, refrigerant injection devices and repair devices. Among them: the sensor is as figure 2 In the array arrangement shown, the area occupied by each sensor is 1m×1m, each sensor has a number, and the location of the leakage area can be accurately determined according to the number; the refrigerant injection device is used when the sensor detects a leak, Spray the refrigerant medium to the leakage area, and the refrigerant vaporizes, taking away the heat of the tank and molten salt near the leakage point, causing the molten salt near the leakage wound to solidify, forming such a shape on the inner and outer walls. Figure 5-6 The first solidified salt block 5 and the second solidified salt block 6 shown prevent further leakage of the molten salt; the cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com