Textile machine for making cross-wound bobbins and method of operating such textile machine

A technology for cross-winding bobbins and textile machines. It is used in textiles and papermaking, spinning machines, open-end spinning machines, etc., and can solve problems such as increased differences, shift of station units, and mechanical vibrations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

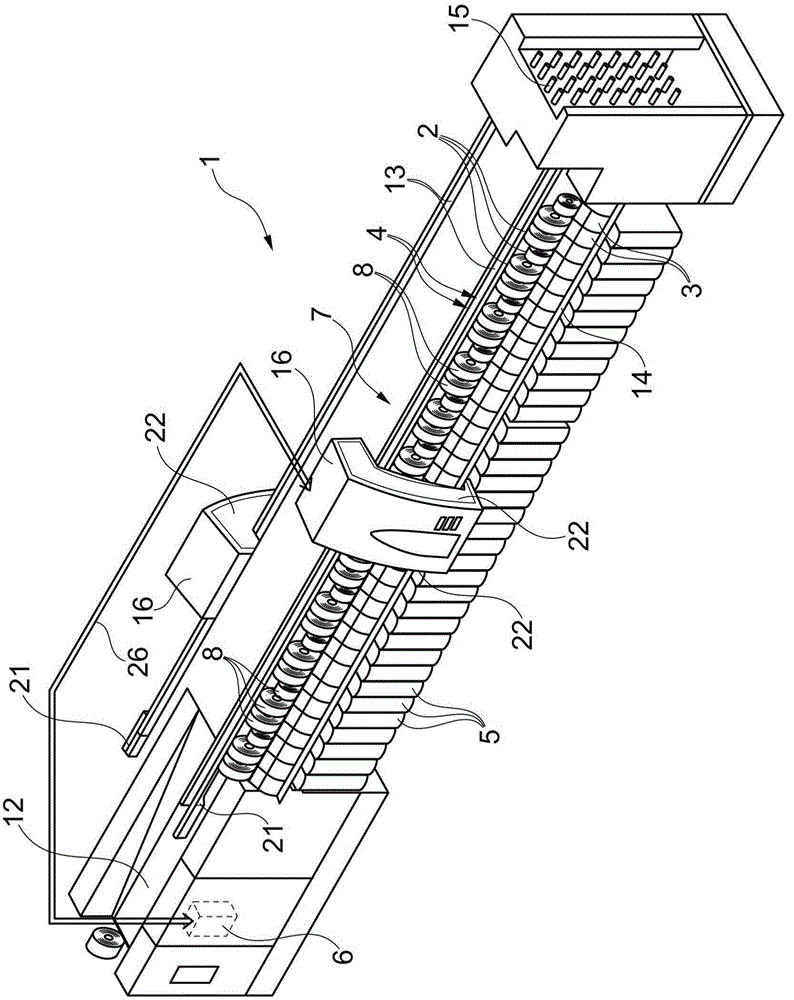

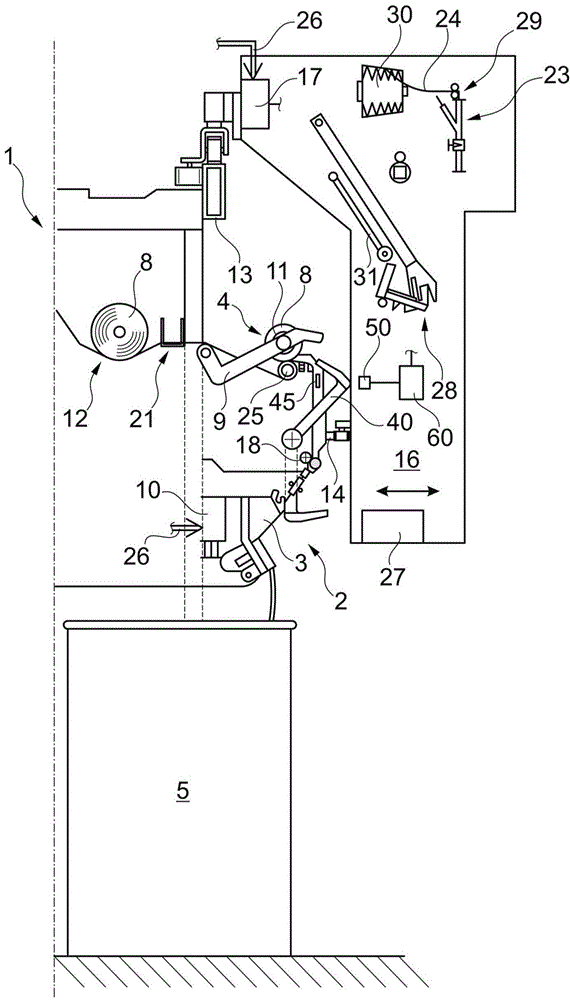

[0033]exist figure 1 An open-end spinning machine 1 is shown in , which has a plurality of stations 2 each of which is equipped with an open-end spinning device 3 and a winding device 4 . The open-end spinning machine 1 also has two identical service groups 16 .

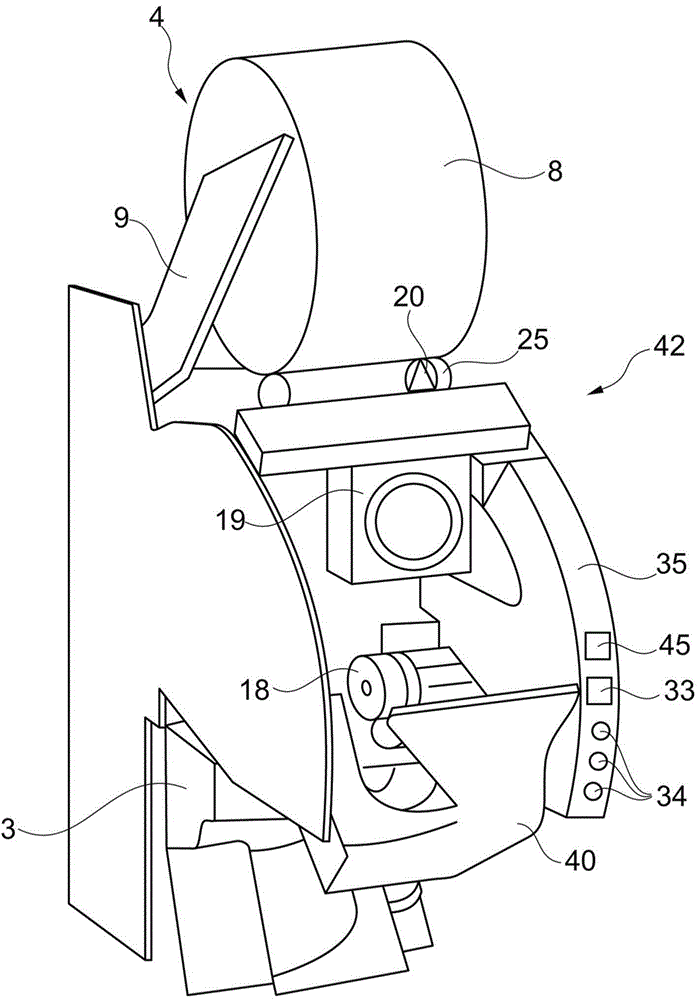

[0034] In the spinning device 3, the fiber sliver fed into the spinning drum 5 is spun into a yarn, which is drawn out of the spinning device 3 by means of a delivery roller pair 18 and wound up on the winding device 4 Wind the bobbin 8 into a cross. Winding device 4 such as figure 2 Shown is equipped with a creel 9 for rotatably holding an empty bobbin 11 or cross-wound bobbin 8 and a winding drum 25 for rotating the empty bobbin 11 or cross-wound bobbin 8 . The open-end spinning machine 1 also has a central control unit 6 which is connected via a bus system 26 to the control unit 10 of the workstation itself. In addition, such a textile machine 1 has a cross-wound bobbin delivery device 12 for handling complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com