A kind of manufacturing method of non-smoked salt glaze ceramics

A manufacturing method and non-smoking technology, which is applied in the field of manufacturing non-smoking salt glaze ceramics, can solve the problems of high energy consumption, difficulty in treatment, and restrictions on product production, and achieve the effect of reducing the firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

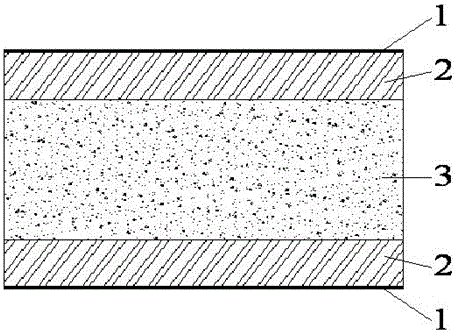

Image

Examples

Embodiment 1

[0019] Embodiment 1: Select the surface glaze slurry of corresponding ceramics, and add 50gNaCl / 100mL glaze slurry into the glaze slurry. Mix thoroughly and allow to dissolve well. Use conventional methods such as glaze dipping, glaze spraying, etc. for glazing, drying, and firing. The firing temperature is about 1200°C, and a ceramic product with a vitrified layer thickness of 1mm can be obtained.

Embodiment 2

[0020] Example 2: Select the surface glaze slurry of the corresponding ceramics, and add 5g NaCl / 100mL glaze slurry, 5ml water glass / 100mL glaze slurry, and 10g borax / 100mL glaze slurry into the glaze slurry. Mix thoroughly and allow to dissolve well. Use conventional methods such as glaze dipping, glaze spraying, etc. for glazing, drying, and firing. The firing temperature is about 1100°C, and a ceramic product with a vitrified layer thickness of 1mm can be obtained.

Embodiment 3

[0021] Example 3: Select the surface glaze slurry of the corresponding ceramics, add 50g NaCl / 100mL glaze slurry, 10mL water glass / 100mL glaze slurry, and 5g borax / 100mL glaze slurry into the glaze. Mix thoroughly and dissolve well. Use conventional methods such as glaze dipping, glaze spraying, etc. for glazing, drying, and firing. The firing temperature is 1160°C, and a ceramic product with a vitrified layer thickness of 3mm can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com