Sealing treatment method for aluminum alloy anode oxide film

An anodic oxide film and treatment method technology, applied in the field of sealing, can solve the problems of loss of sealing effect, easy corrosion of oxide film, etc., and achieve the effect of improving corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

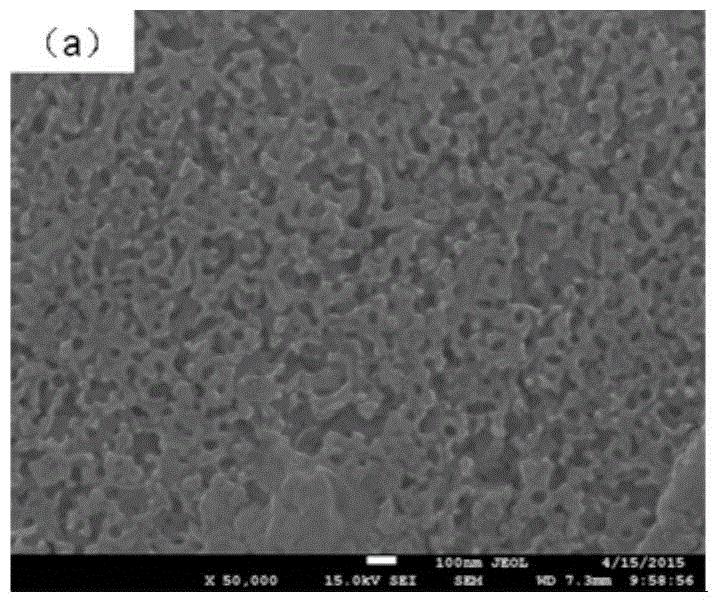

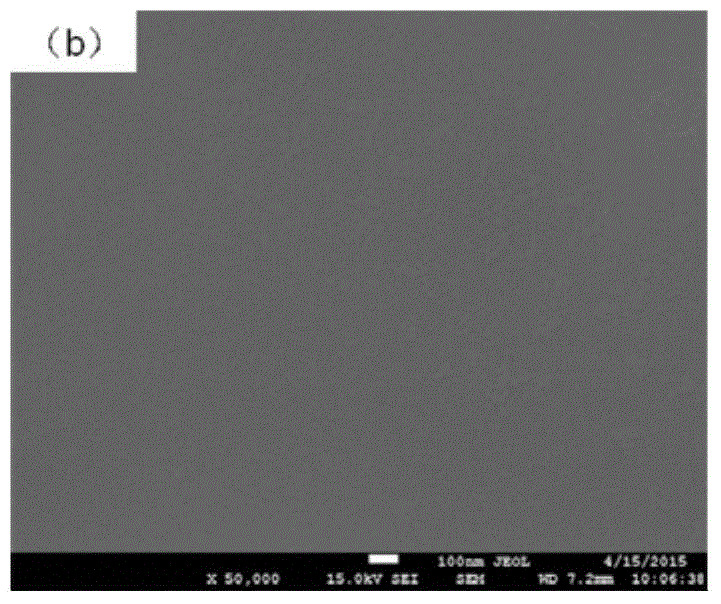

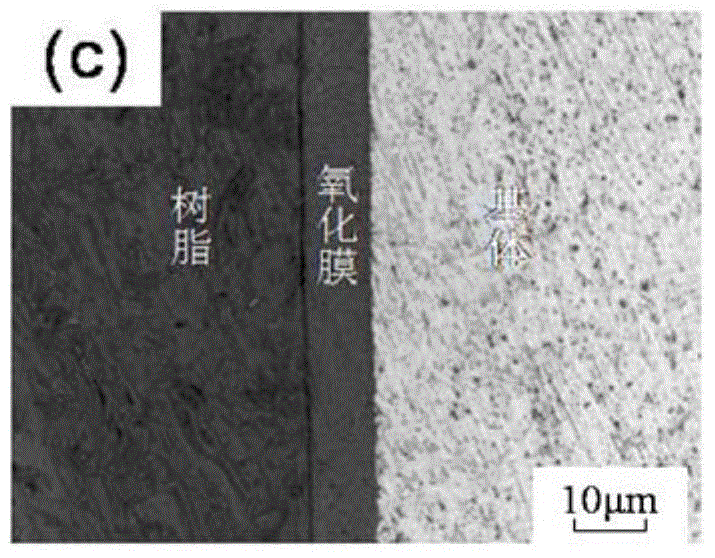

Image

Examples

specific Embodiment

[0030] Test 1: Phosphate sealing. Using Al(H 2 PO 4 ) 3 The solution is sealed, the Al(H 2 PO 4 ) 3 The solution synthesis method is: weigh a certain amount of H 3 PO 4 Solution and heated to 85 ° C, according to the ratio of the amount of substances Al / P = 1:3, to H 3 PO 4 Slowly add solid Al(OH) into the solution 3 , and stirred until solid Al(OH) 3 completely dissolved to form Al(H 2 PO 4 ) 3 solution, and then use deionized water to prepare Al(H 2 PO 4 ) 3 The solution is diluted, and the diluted Al(H 2 PO 4 ) 3 The mass fraction of the solution is 10%. Next, the prepared Al(H 2 PO 4 ) 3 The solution was evenly brushed on the aluminum alloy anodized film, and placed in the air to cure for 12 hours, and then the Al(H 2 PO 4 ) 3 The aluminum alloy anodized film of the solution was heat-treated at 20-250°C for 30 minutes, then air-dried naturally, and then the prepared Al(H 2 PO 4 ) 3 The solution is evenly brushed onto the aluminum alloy anodized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap