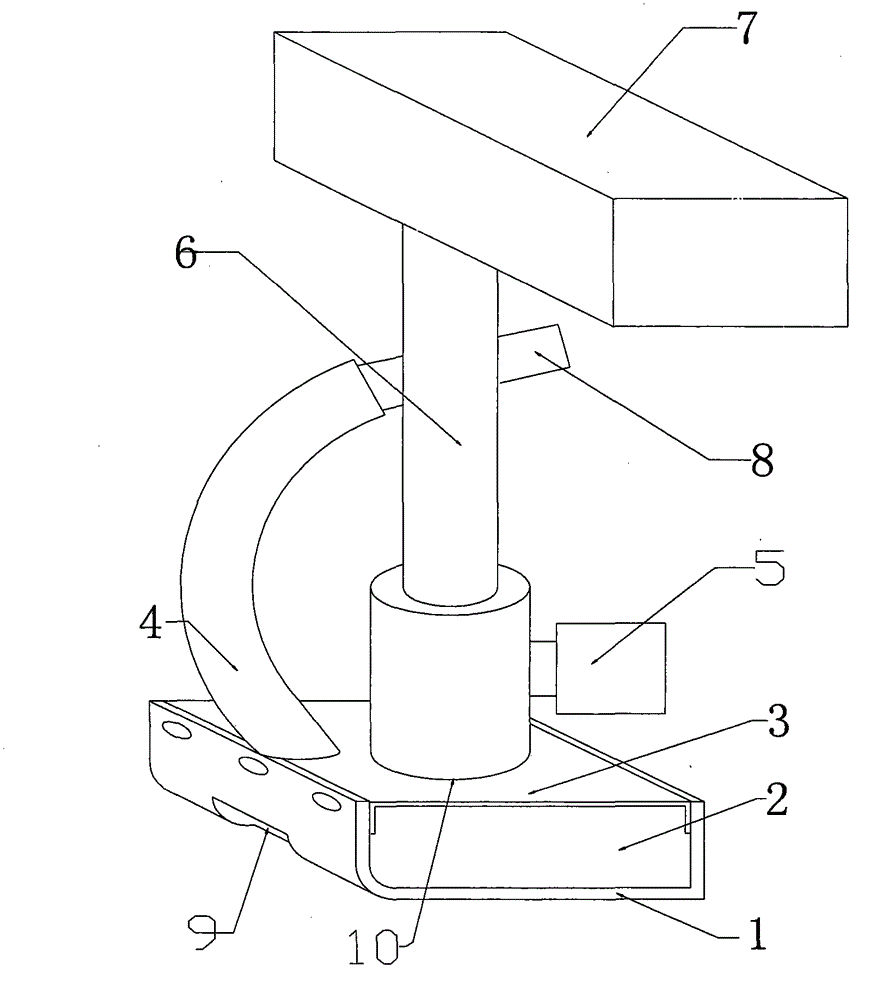

Pavement crack pouring machine synchronous preheating apparatus

A technology of a preheating device and a seam filling machine, which is applied to roads, roads, road repair and other directions, can solve the problems of very large interference of passing vehicles, consumption of large power and human resources, and complicated operation procedures, so as to save seam filling materials. The effect of consumption, labor saving, and low cost of seam filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

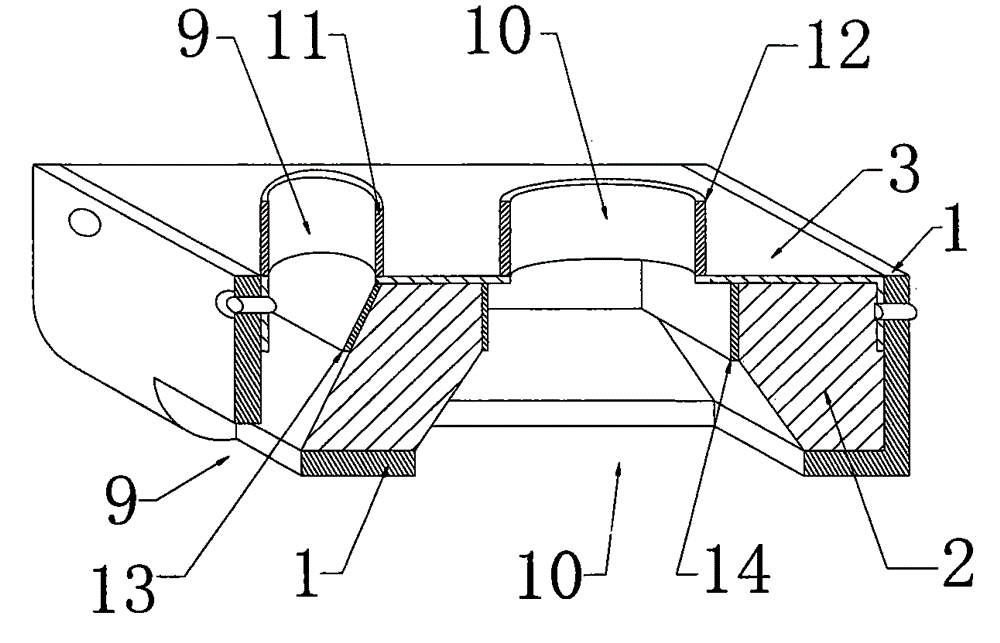

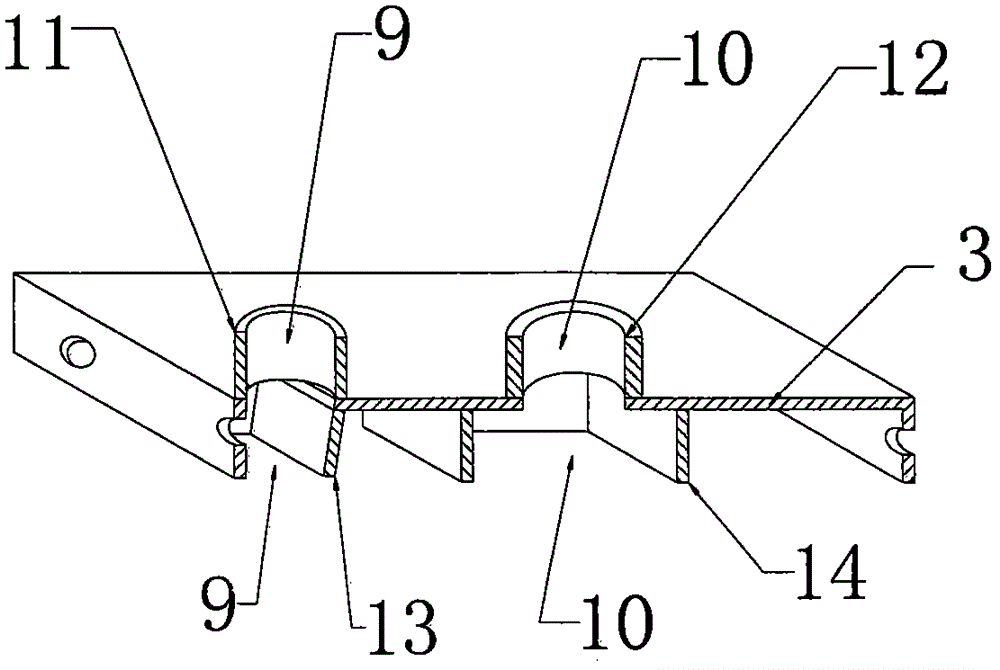

[0025] The preheating seam cleaning channel 9 and the joint filling material channel 10 are arranged one after the other in a device composed of a friction plate 1, an elastic body 2, and a valve mounting frame 3, wherein the elastic body 2 adopts elastic Made of high-quality and high-temperature-resistant rubber material, a trapezoidal gap with a large upper part and a smaller lower part is provided on the front end as part of the preheating seam cleaning channel 9, and a trapezoidal central through hole with a smaller upper part and a larger lower part is provided at the center As part of the caulking material channel 10, an installation step is provided on the upper side of the front and rear ends of the elastic body 2. The gap between the front end of the elastic body 2 and the central through hole is greater than 1 cm. It is made into an arc shape with a radius of 1 cm. The friction plate 1 is U-shaped and made of wear-resistant rubber material. Completely matched and clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com