Piston-energy-storage toilet water flushing device

A flusher and piston technology, applied in the field of flushing devices, can solve the problems of large ceramic volume, small water impact force, waste of water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below with reference to accompanying drawing:

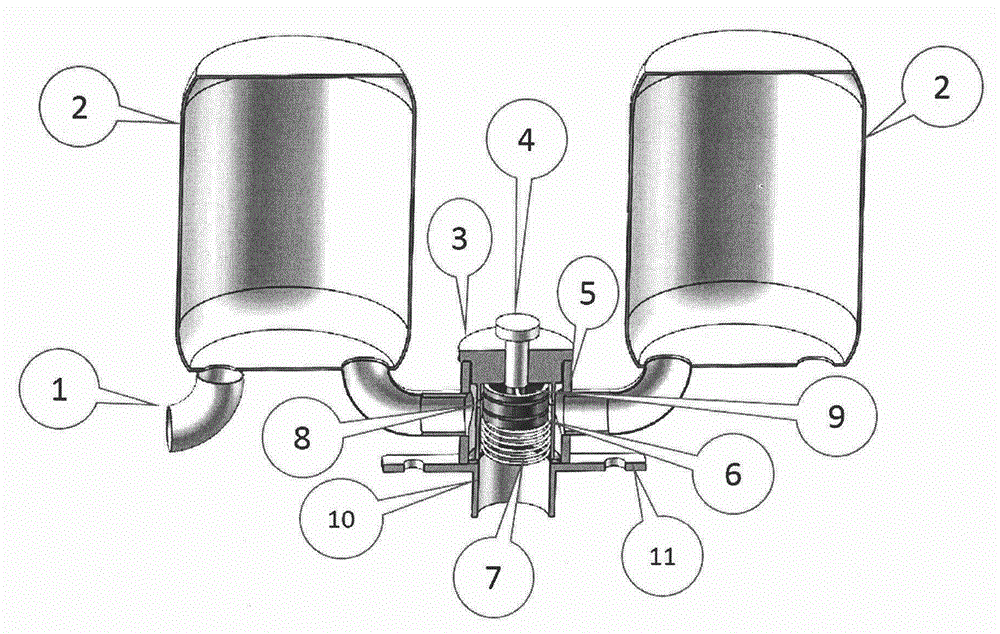

[0017] Referring to the accompanying drawings, the piston energy-storage toilet flusher includes: 1 water inlet, 2 small water tanks, 3 piston cylinders, 4 pressure rods, 5 four-way pipes, 6 pistons, 7 return springs, 8 side holes, 9 piston diversion hole, 10 drain port, 11 mounting bracket.

[0018] As shown in the accompanying drawing, 2 small water tanks are connected with 3 piston barrels, 6 pistons, 7 return springs, 4 depression bars, and 10 drain outlets by 5 four-way pipes. The piston valve is composed of 3 piston barrels, 4 pressure rods, 5 four-way pipes, 6 pistons, 7 return springs, 8 side holes, 9 piston diversion holes, and 10 drain ports.

[0019] Water intake process: The water pressure of the tap water pipe network for urban residents is about 0.25 MPa. The water inlet nozzle 1 of the 2 small water tanks is directly connected with the residential tap wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com