In-situ pore water sampling column and water sampling method thereof

A collection method and pore water technology, applied in the direction of sampling devices, etc., can solve the problems of Bou-Rouch sampler equipment structural damage, Bou-Rouch sampler work failure, and inability to meet the requirements effectively, so as to improve adaptability and resistance , The operation method is simple and standardized, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

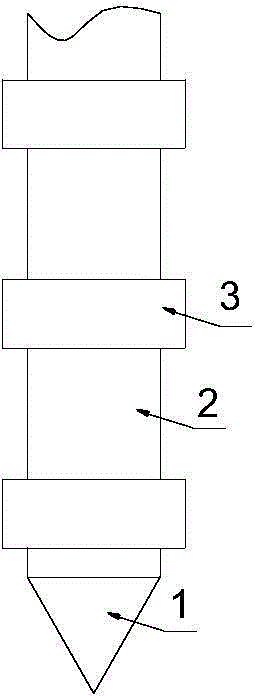

[0019] Such as figure 1 with 2 The in-situ pore water collection column includes a drilling head 1 and a water collection device unit 2, at least two water collection device units 2 are connected by clamps 3, and the water collection device units 2 are coaxially distributed. The head 1 is connected with the water collector unit 2 through the clamp 3, and is coaxially distributed with the water collector unit 2.

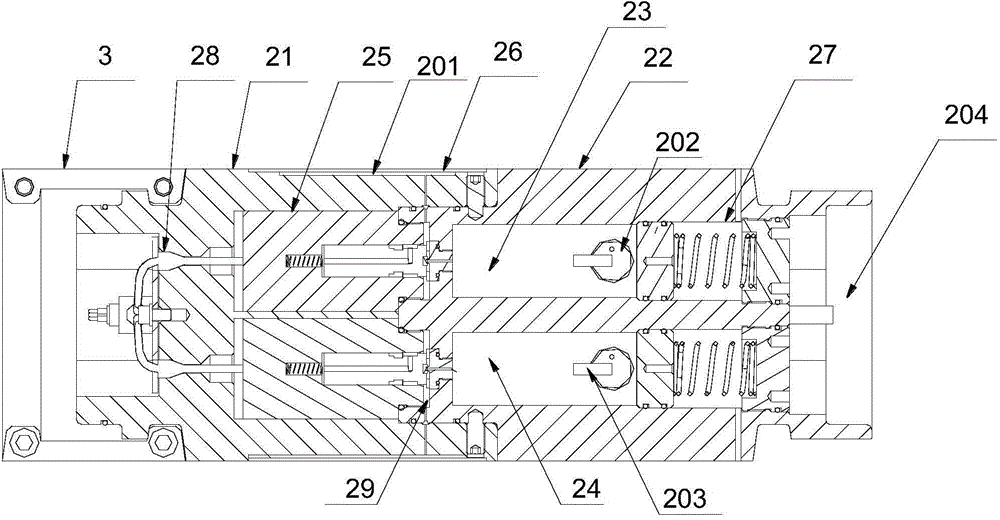

[0020] In the present embodiment, the described water collector unit 2 includes a solenoid valve installation bucket 21, a sampling cylinder 22, a waste water cabin 23, a sample water cabin 24, a solenoid valve 25, a composite filter layer 26, a balance piston 27, a control cable 28 and The guide tube 29, the electromagnetic valve insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com